Air filter blowback self-cleaning device for air compressor

An air compressor and air filtration technology, applied in mechanical equipment, transportation and packaging, dispersed particle filtration, etc., can solve the problems of high resistance, high operation and maintenance costs, and rapid loss of filter element and filter paper, reducing power consumption, improving Filtering effect, the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

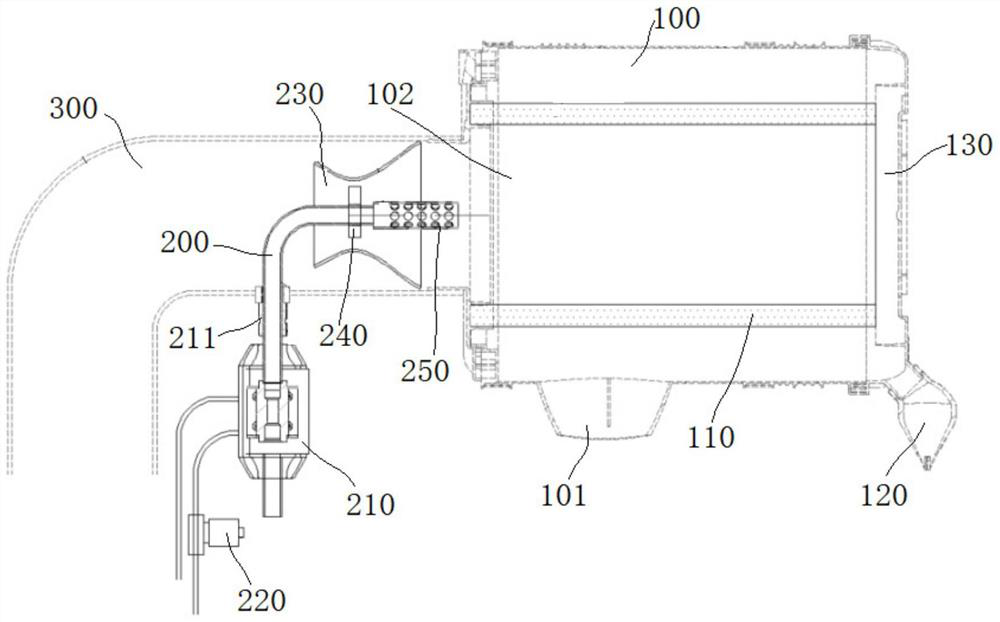

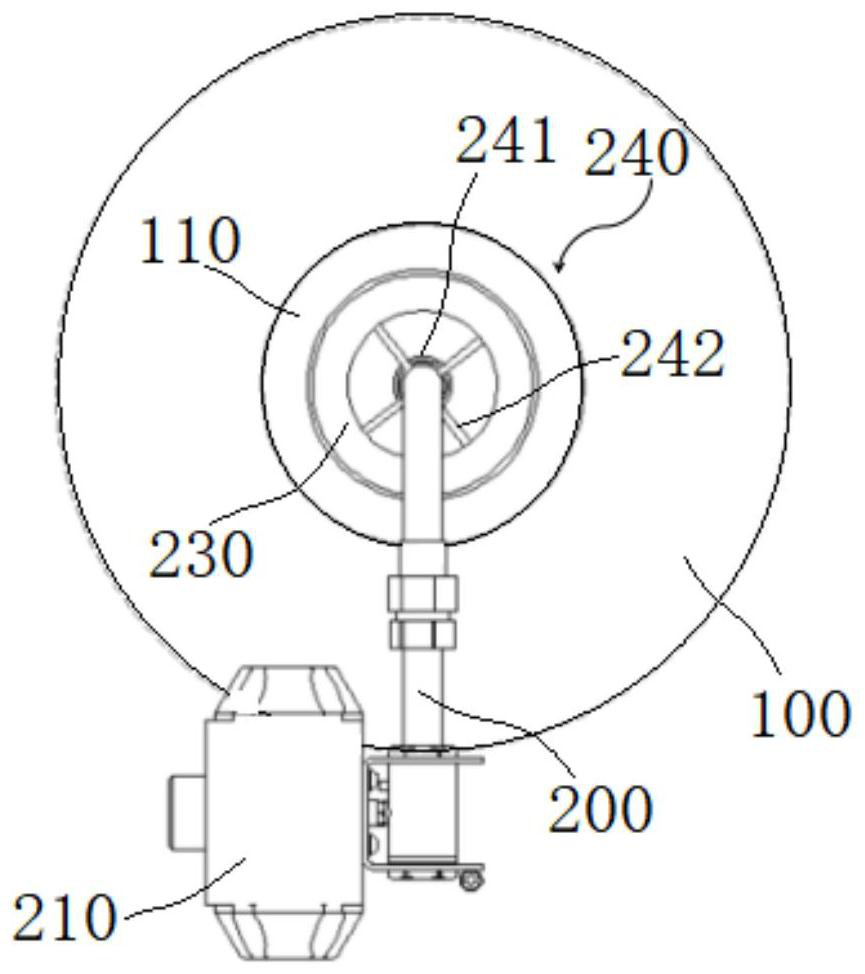

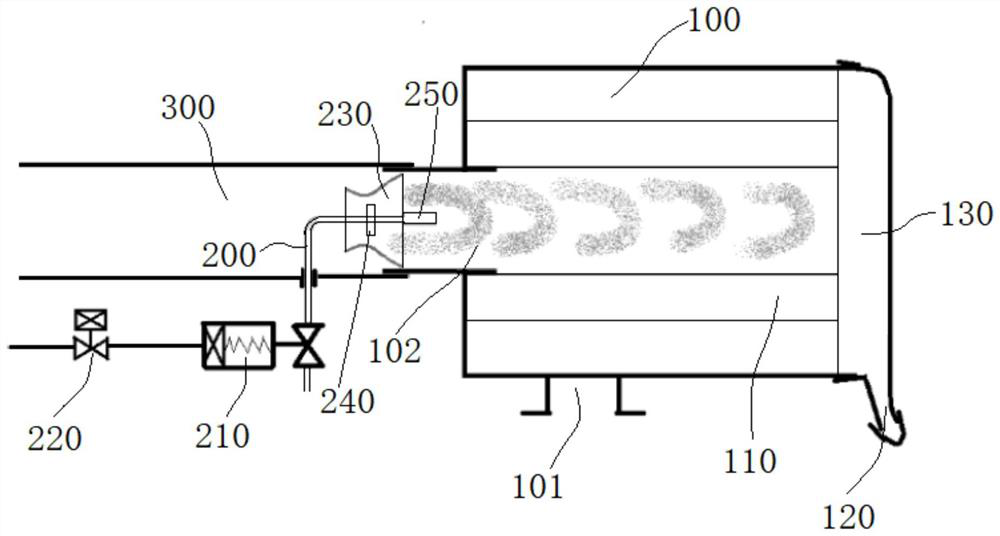

[0030] combine Figure 1-Figure 3 , an air filter blowback self-cleaning device for an air compressor in this embodiment includes an air filter housing 100, and a self-cleaning air filter element 110 is arranged inside the air filter housing 100, and the self-cleaning air filter element 110 There is a layer of nano-coating on the outer periphery. On the basis of the fiber filter element, a layer of nano-coating is applied on the outer periphery of the fiber filter element by using nano-coating or spinning process, which can filter dust and impurities in the self-cleaning air filter element 110. The outer surface prevents dust and impurities from entering the interior of the self-cleaning air filter element 110, which effectively improves the filtering effect and facilitates subsequent purging work. In this embodiment, the axial side of the self-cleaning air filter element 110 is the air filter exhaust port 102, and the air filter exhaust port 102 is provided with a purging uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com