Method for cleaning oxidized finished copper wires

A cleaning method and copper wire technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as environmental pollution, cumbersome methods, and incomplete treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

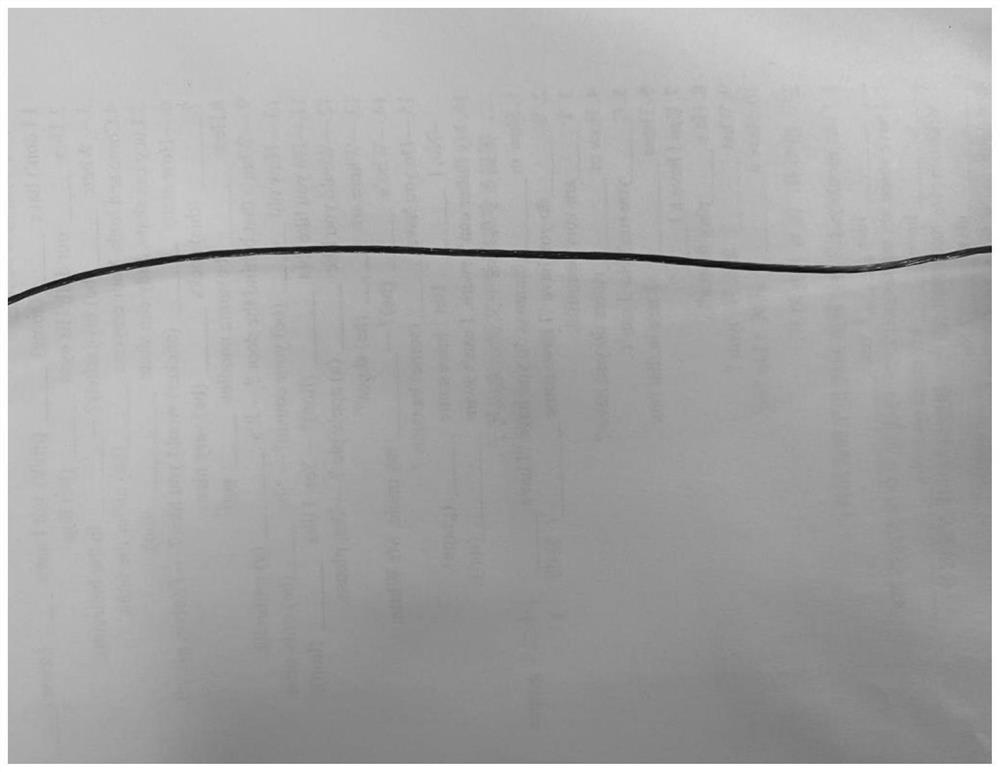

[0031] An embodiment of the present invention provides a method for cleaning finished copper wire after oxidation, comprising the following steps:

[0032] (1) Wind the oxidized copper wire to be treated on the iron pan and put it in the furnace gall of the annealing furnace;

[0033] (2) Put industrial alcohol with a purity of 95% in a glass bottle with a capacity of 500ml, then place it in an annealing furnace, and vacuumize the furnace to minus 0.1MPa;

[0034] (3) Pass carbon dioxide into the furnace until the pressure in the furnace is 0.25MPa, and then heat it up,

[0035] Specifically, three heating points, upper, middle, and lower, are set in the annealing furnace to uniformly heat the furnace. Among them, the heating temperature of the upper phase is 420°C, the heating time is 80 minutes, and the holding time is 40 minutes; the heating temperature of the middle phase is 420°C, the heating time is 60min, and the holding time is 40min; the heating temperature of the lo...

Embodiment 2

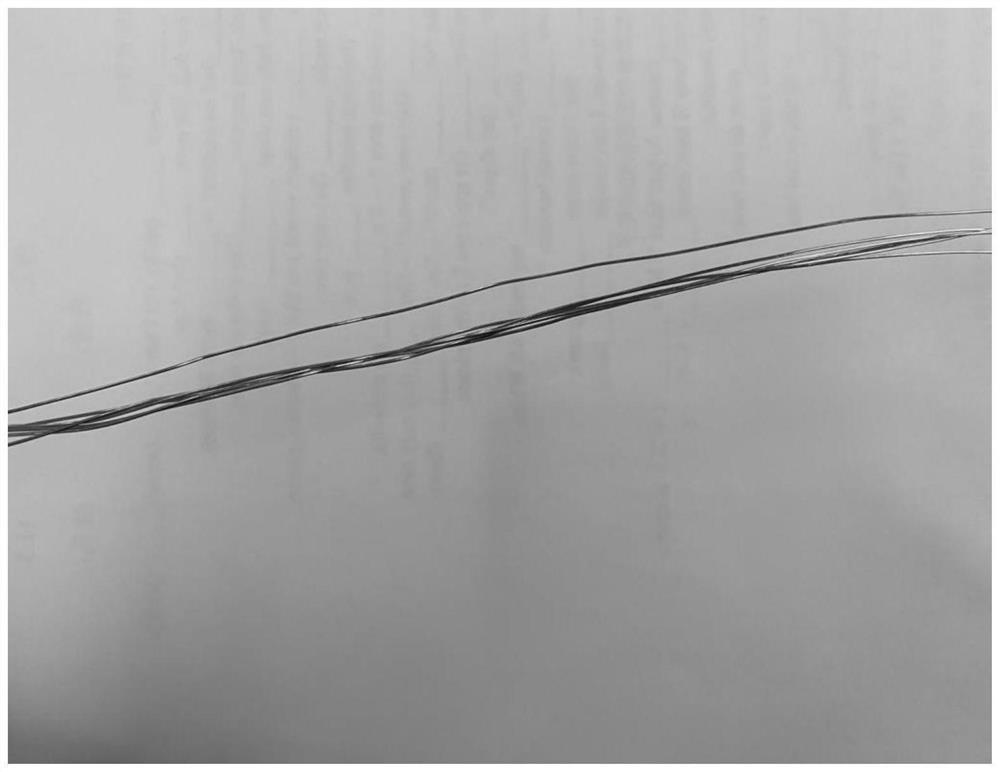

[0039] An embodiment of the present invention provides a method for cleaning finished copper wire after oxidation, comprising the following steps:

[0040] (1) Wind the oxidized copper wire to be treated on the iron pan and put it in the furnace gall of the annealing furnace;

[0041] (2) Put industrial alcohol with a purity of 99% in a glass bottle with a capacity of 500ml, then place it in an annealing furnace, and vacuumize the furnace to minus 0.1MPa;

[0042] (3) Pass carbon dioxide into the furnace until the pressure in the furnace is 0.35MPa, then heat,

[0043] Specifically, three heating points, upper, middle and lower, are set in the annealing furnace to uniformly heat the furnace. Among them, the heating temperature of the upper phase is 590 ° C, the heating time is 80 min, and the holding time is 40 min; the heating temperature of the middle phase is 590°C, the heating time is 60min, and the holding time is 40min; the heating temperature of the lower phase is 590°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com