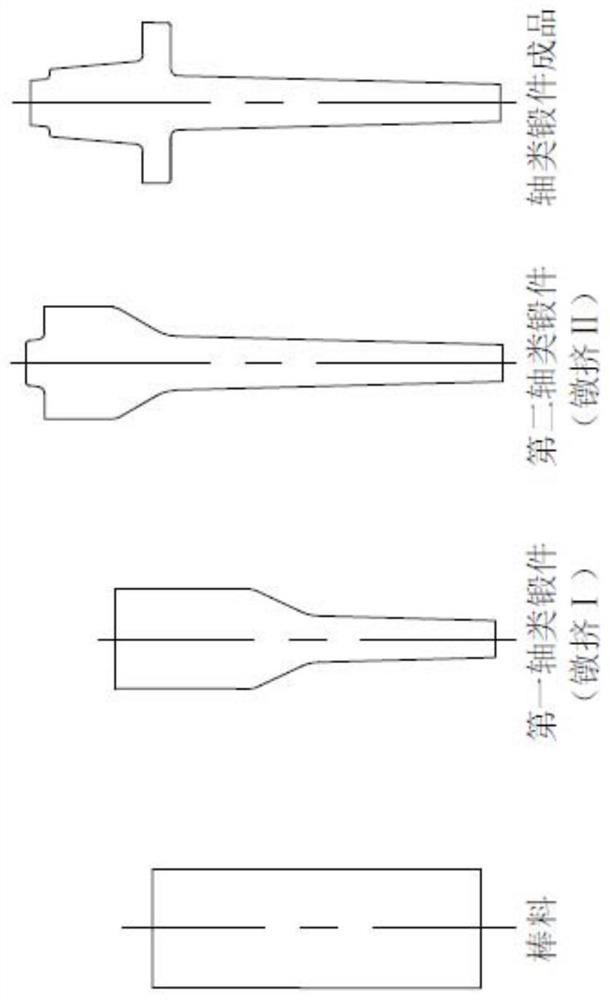

Forging method for shaft forgings and blank-making and finish-forging die structure of shaft forgings

A technology for forgings and shafts, which is applied to the forging method of shaft forgings and the structure of blanks and final forging molds, can solve the problems of production cost load, low diversity of shaft products, etc., and achieves small investment and avoids production. High cost and the effect of ensuring compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

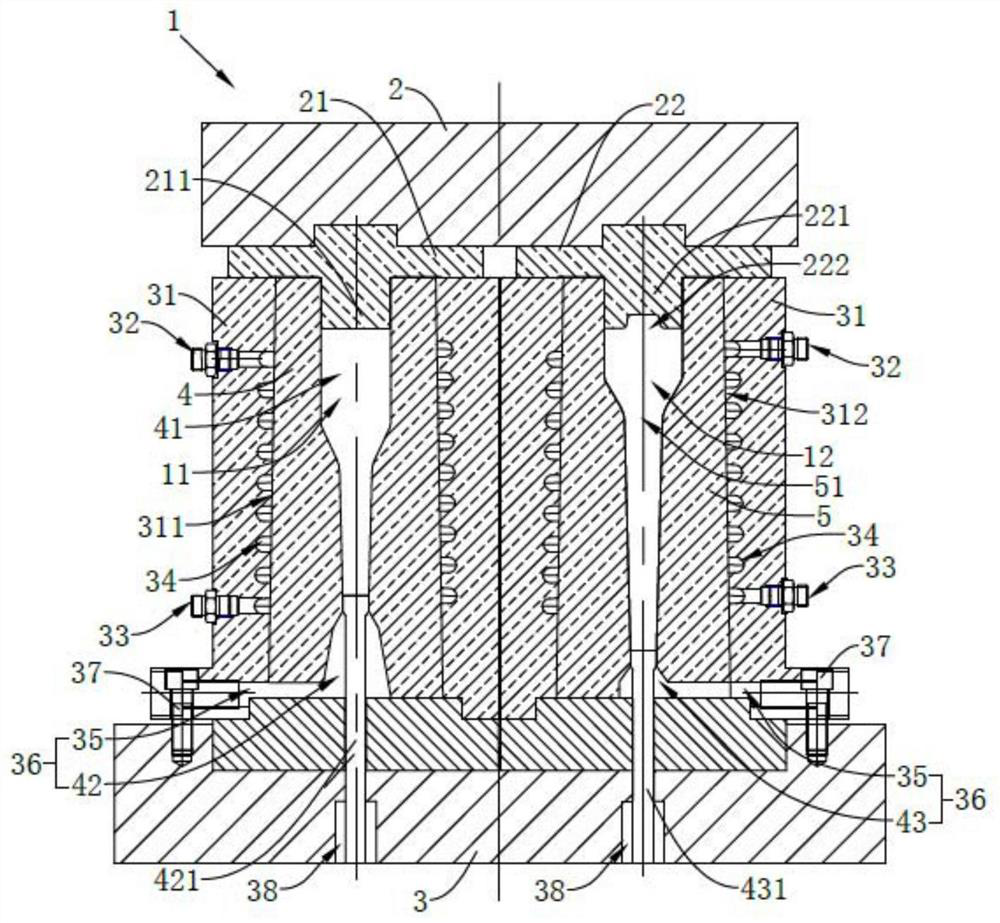

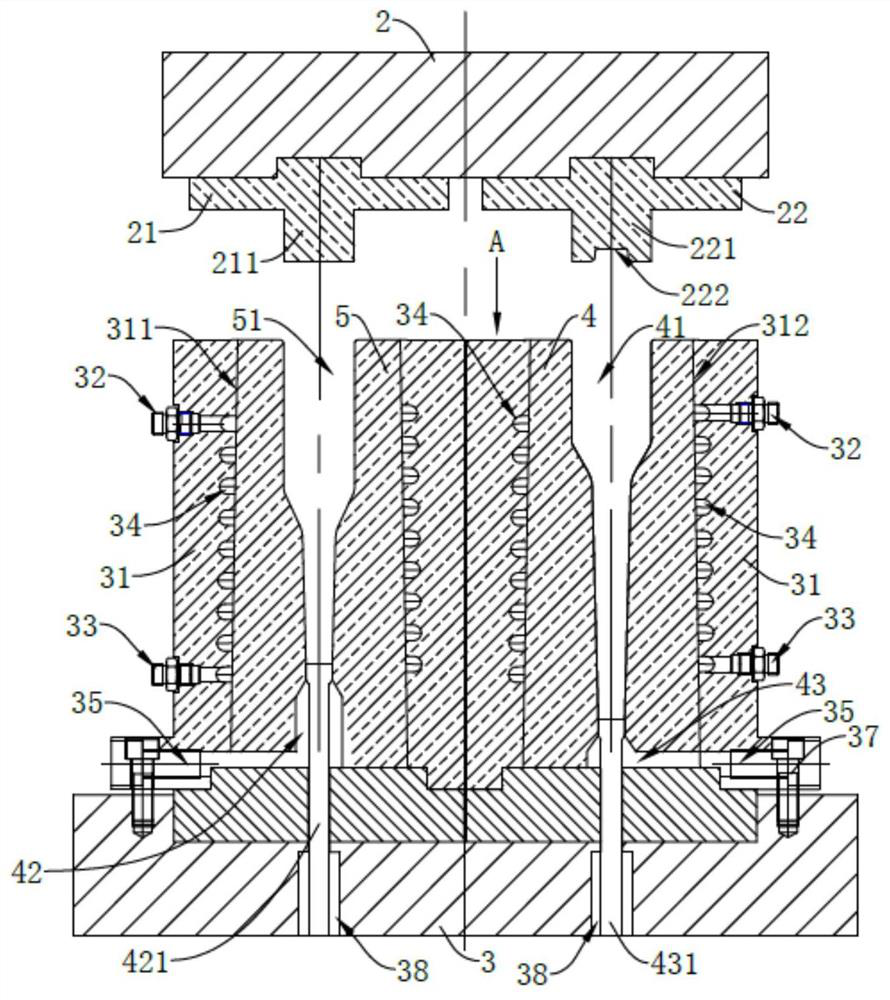

[0047] refer to Figure 1-6 , a kind of shaft-type billet mold structure, comprising a first upper mold fixed plate 2 and a first lower mold fixed plate 3, the top surface of the first lower mold fixed plate 3 is provided with a first lower formwork frame 31, the first lower formwork The top surface of the frame 31 is provided with an Upsetting Extrusion I mold core groove 311 and an Upsetting Extrusion II mold core groove 312, and the Upsetting Extrusion I mold core groove 311 is fixedly provided with the Upsetting Extrusion I lower mold core 4 and the Upsetting Extrusion I lower mold core 4. The top surface is provided with the first forging groove 41 into which the feeding rod is placed. The section diameter of the first forging groove 41 is gradually reduced along the depth direction of the groove. A forging upper extrusion die 21, the bottom surface of the first forging upper extrusion die 21 is provided with a first forging upper insert 211, the first forging upper inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com