Hyperelastic aerogel and preparation method thereof

An airgel and superelastic technology, which is applied in the field of superelastic inorganic material preparation, can solve the problems of low strength and compressive stress that cannot meet the needs of practical applications, and achieve the effects of improving service reliability, improving storage, and reducing free slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Described a kind of superelastic airgel and preparation method thereof, comprise the following steps:

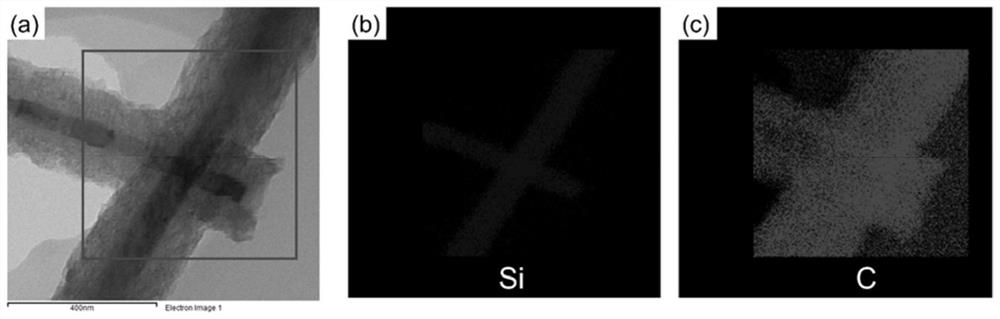

[0041] SiC nanowire airgel or Si 3 N 4 Nanoribbon airgel is used as raw material, and a layer of pyrolytic carbon is deposited on the surface of nanowires by chemical vapor deposition (CVD). The deposited pyrolytic carbon can "weld" the nanowires that originally had only physical contact. A pyrolytic carbon node is formed between them, and the node is fixed and cannot be rotated.

[0042] CVD process: the temperature of chemical vapor deposition is 900-1200°C, the heating rate of the deposition furnace is 0.1-10°C / min, the pressure in the furnace is 1-20kPa, the precursor is methane, and the gas flow rate is 10-200ml / min. The time is 1h~30h.

Embodiment 1

[0044] This embodiment has prepared the density is 40mg / cm 3 superelastic airgel;

[0045] Choose 10mg / cm 3 The SiC nanowire airgel is used as the raw material, placed in the CVD furnace, vacuumed, and the temperature is raised to 800°C at a rate of 10°C / min, and the carbon source precursor gas methane is introduced, and the flow rate of methane is controlled to 10ml / min. Then increase the temperature to 900°C at a rate of 0.1°C / min, and keep it warm for 30 hours to obtain a density of 40mg / cm 3 superelastic airgel.

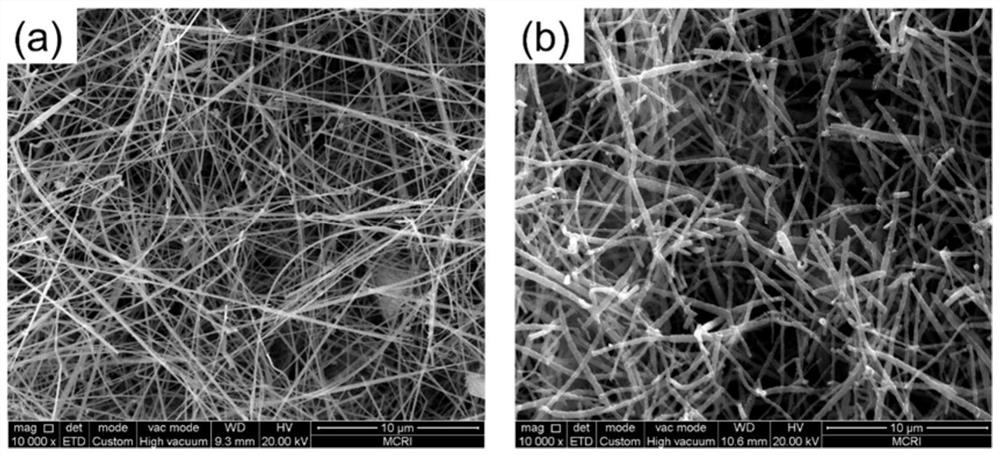

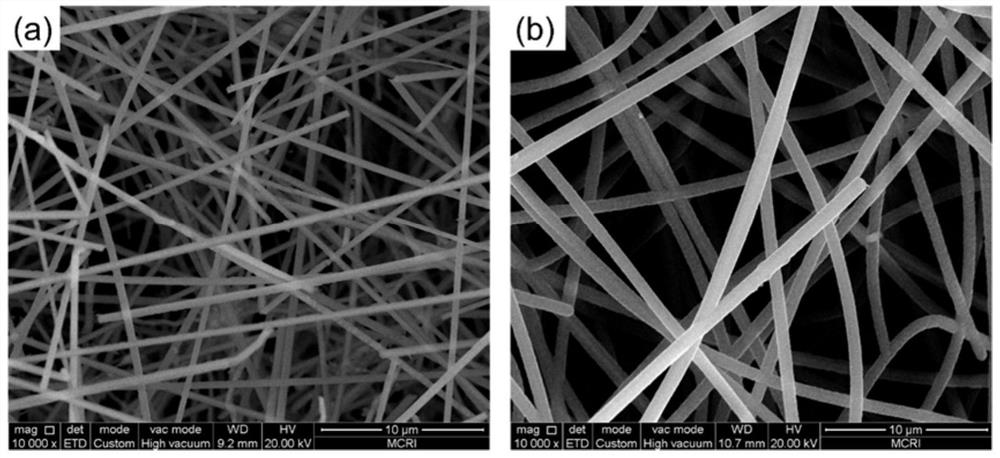

[0046] Such as figure 1 and image 3 As shown, after SiC nanowire airgel was treated with CVD pyrolytic carbon, the nanowires were successfully welded by pyrolytic carbon; after SiC nanowire airgel was treated with CVD pyrolytic carbon, both the strength and compressive have been greatly enhanced to become superelastic aerogels: see Figure 6 ,Such as Figure 6 As shown in (a), the black, blue, purple and green lines represent the stress curves when the co...

Embodiment 2

[0048] This example prepared a density of 10mg / cm 3 superelastic airgel;

[0049] Choose 4mg / cm 3 The SiC nanowire airgel is used as raw material, placed in a CVD furnace, vacuumed, and the temperature is raised to 800°C at a rate of 10°C / min, and the carbon source precursor gas methane is introduced, and the flow rate of methane is controlled to 15ml / min. Then increase the temperature to 1000°C at a rate of 2°C / min, and keep it warm for 6 hours to obtain a density of 10mg / cm 3 superelastic aerogels, such as Figure 4 As shown, the thickness of the pyrolytic carbon layer on the surface of SiC nanowires is 40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com