Concentrated detergent composition

A cleaning composition and composition technology, applied in the direction of detergent composition, organic cleaning composition, detergent compounding agent, etc., can solve the problems of high temperature, cumbersome preparation, etc., and achieve the effect of improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

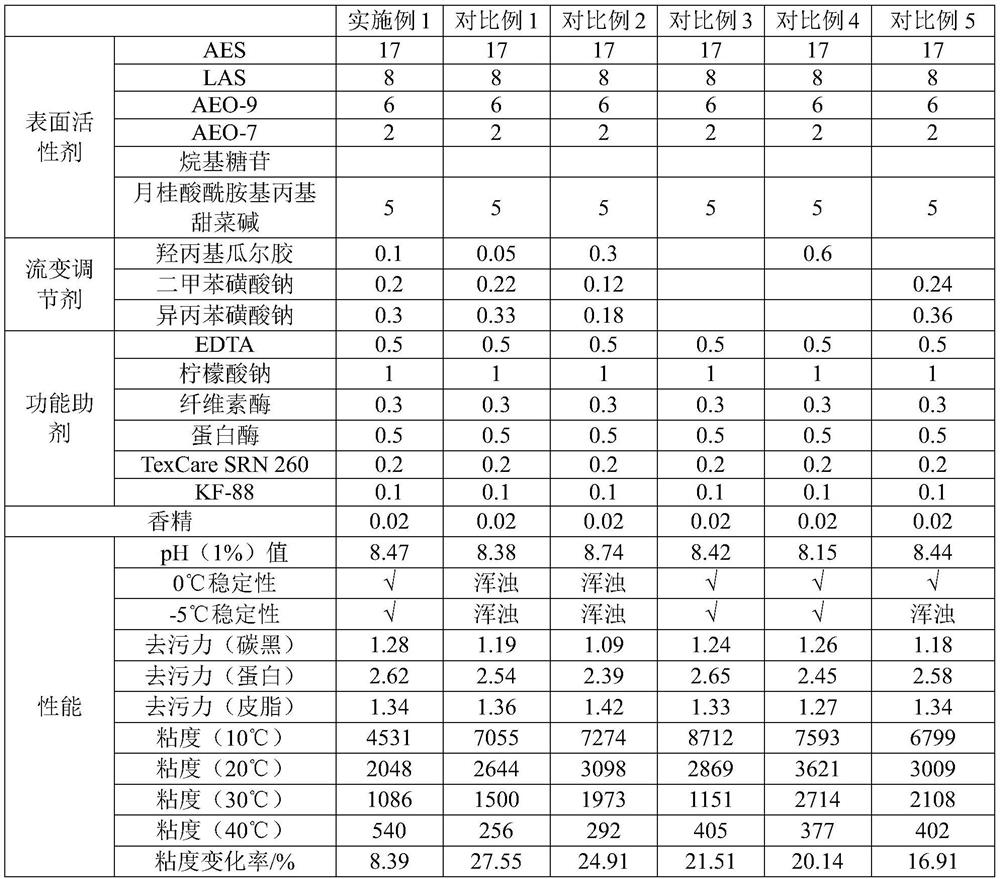

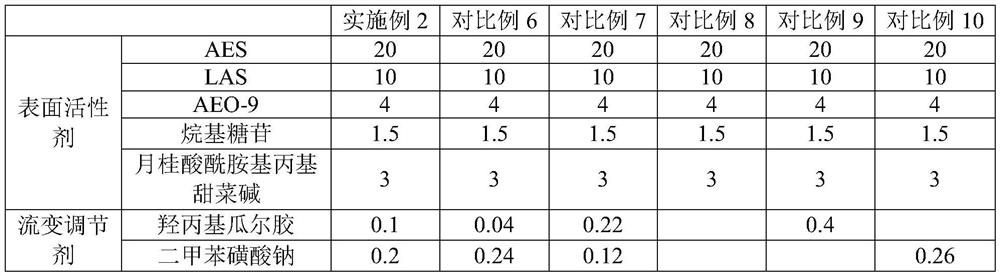

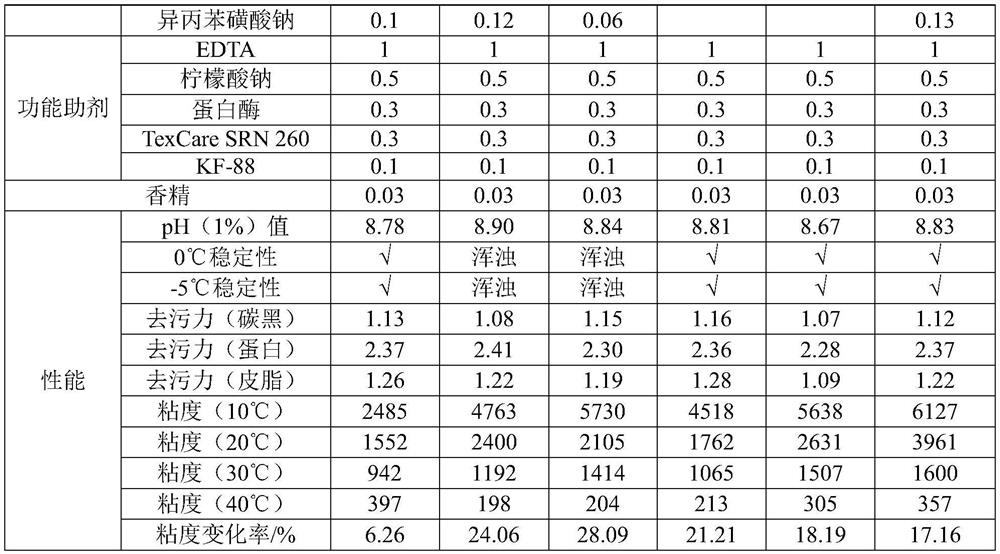

Embodiment 1~3 and comparative example 1~15

[0060] According to the formula of following table 1~3, prepare the concentrated detergent composition of embodiment 1~3 and comparative example 1~15 through the following steps:

[0061] (1) Mix deionized water, zwitterionic surfactant and anionic surfactant in proportion, and stir evenly at 45-48°C;

[0062] (2) cooling the solution to room temperature, adding a rheology modifier and a nonionic surfactant in turn to the solution prepared in step (1), mixing and stirring until the solution is evenly dissolved until completely dissolved;

[0063] (3) Cool the solution to room temperature, add functional additives in turn to the solution prepared in step (2), mix and stir until the solution is uniform, and adjust the pH of the solution to 8.0-9.0 to obtain a concentrated detergent composition.

[0064] In Tables 1 to 3, the content of each component is weight percentage, and the balance is water; if not filled in, the added amount is 0.

[0065] Performance tests were carried ...

Embodiment 4~6 and comparative example 16~18

[0080] According to the formula of following table 4, prepare the concentrated detergent composition of embodiment 4~6 and comparative example 16~18 through the following steps:

[0081] (1) Mix deionized water, zwitterionic surfactant and anionic surfactant in proportion, and stir evenly at 45-48°C;

[0082] (2) cooling the solution to room temperature, adding a rheology modifier and a nonionic surfactant in turn to the solution prepared in step (1), mixing and stirring until the solution is evenly dissolved until completely dissolved;

[0083] (3) Cool the solution to room temperature, add functional additives in turn to the solution prepared in step (2), mix and stir until the solution is uniform, and adjust the pH of the solution to 8.0-9.0 to obtain a concentrated detergent composition.

[0084] In Table 4, the content of each component is weight percentage, and the balance is water; if it is not filled in, the added amount is 0.

[0085] The concentrated detergents of E...

Embodiment 7~10 and comparative example 19~22

[0090] According to the formulation of the following table 5, the concentrated detergent compositions of Examples 7-10 and Comparative Examples 19-22 were prepared through the following steps:

[0091] (1) Mix deionized water, zwitterionic surfactant and anionic surfactant in proportion, and stir evenly at 45-48°C;

[0092] (2) cooling the solution to room temperature, adding a rheology modifier and a nonionic surfactant in turn to the solution prepared in step (1), mixing and stirring until the solution is evenly dissolved until completely dissolved;

[0093] (3) cooling the solution to room temperature, sequentially adding functional additives to the solution prepared in step (2), mixing and stirring until the solution is uniform, and adjusting the pH of the solution to 8.0-9.0 to obtain a concentrated detergent composition.

[0094] In Table 5, the content of each component is weight percentage, and the balance is water; if not filled, the added amount is 0.

[0095]Perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com