Vibrating and washing pile inverted filter construction method

A construction method and a technology for an anti-filter layer, which are applied in separation methods, chemical instruments and methods, and filter circuits, etc., can solve the problems of inability to form an effective filter plug section, labor-intensive workers, and easy damage, and achieve non-deformation resistance. tearing ability, low labor intensity of workers, and the effect of ensuring construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0023] In conjunction with the accompanying drawings.

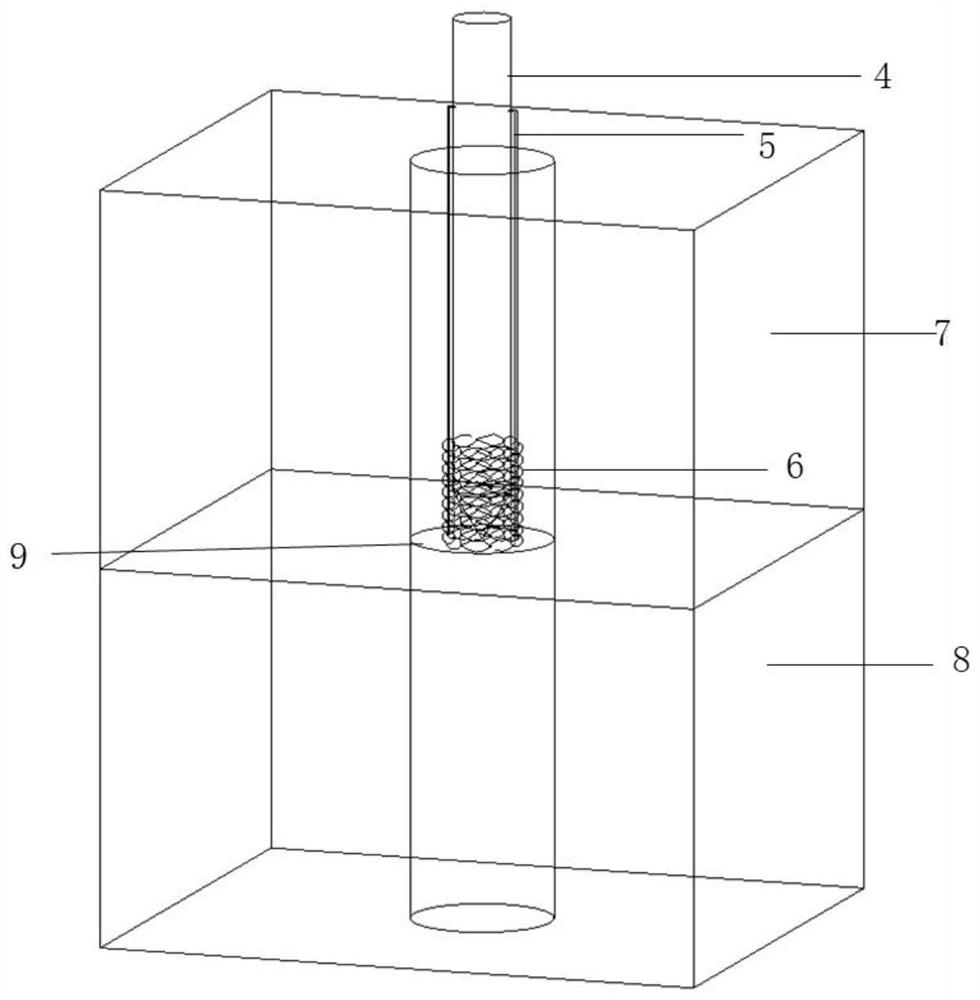

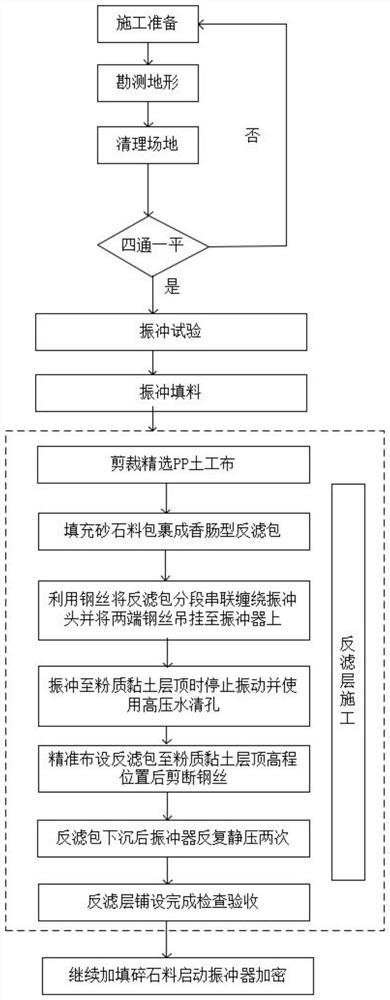

[0024] As shown in the figure, the present invention proposes a construction method for the precise deployment of a "sausage-shaped" hanging filter tube bag for a vibratory pile filter layer, using woven or woven PP geotextiles to replace traditional filament non-woven geotextiles , this kind of geotextile has good performances such as light weight, low cost, corrosion resistance, filter drainage, isolation, and tear resistance. Hang the steel wire, rotate and place the disc to accurately arrange the reverse filter tube bag, and ensure the forming qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com