Method for reinforcing concrete frame joints

A technology of concrete and concrete beams, which is applied in building maintenance, construction, building construction, etc., can solve problems such as insufficient bearing capacity, increased structure self-weight, complex construction, etc., to increase rigidity and ultimate strength, increase maximum bearing capacity, and meet The effect of space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, but do not limit the rights thereof.

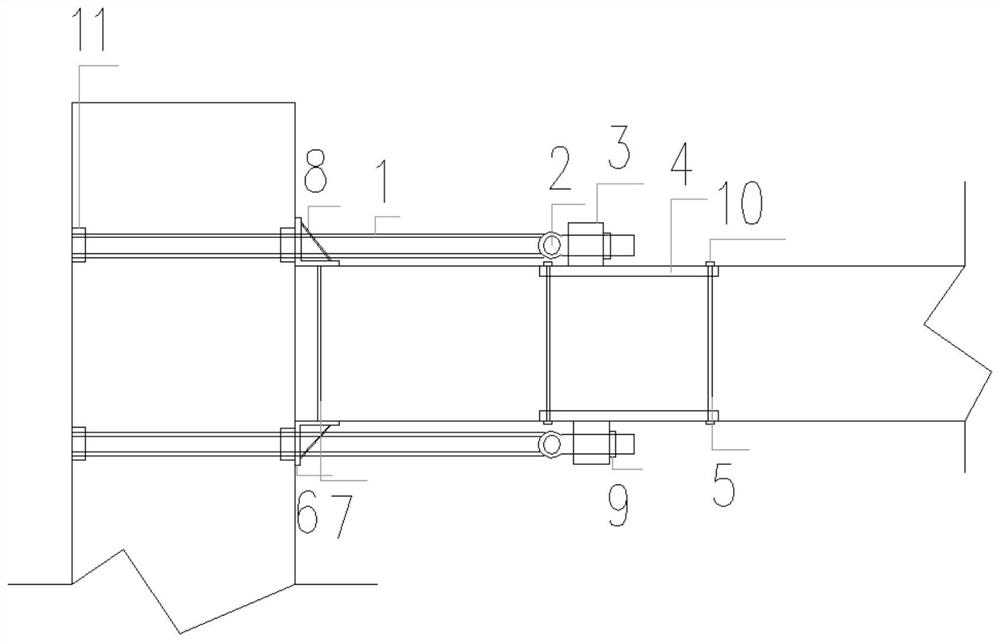

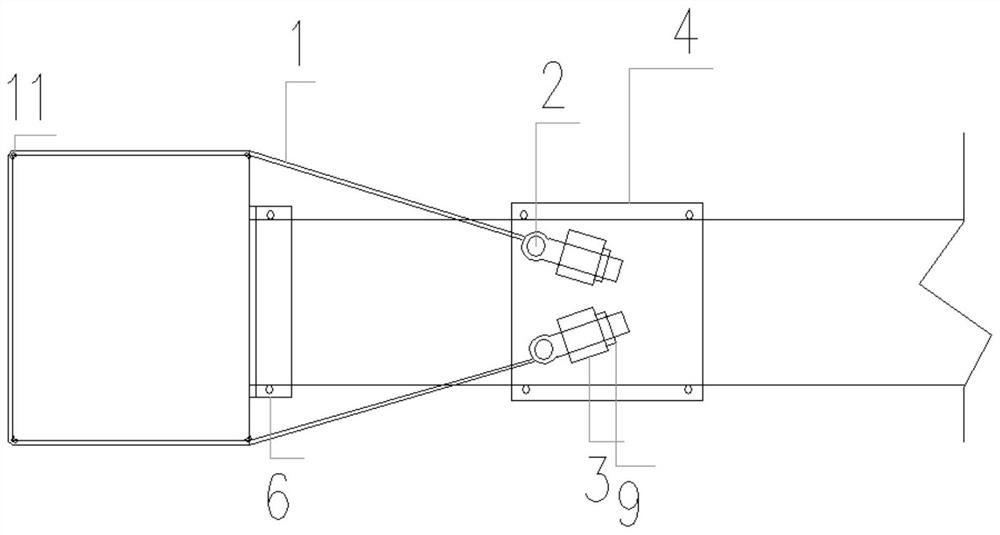

[0027] In the picture: 1. Steel wire rope, 2. Bolt with holes, 3. Cube block, 4. Special steel plate, 5. Long bolt, 6. Angle steel, 7. Long bolt, 8. Diagonal brace, 9. Nut, 10. Nut, 11. Grooved backing plate.

[0028] A method for reinforcing concrete frame joints, the steps of which are as follows:

[0029] (1) According to the area under the concrete beam, prepare a special anchoring steel plate, the area of the special anchoring steel plate is larger than the area under the beam, the four corners are opened, and the special steel plate is welded with cubic steel blocks;

[0030] (2) A special rectangular steel plate is placed on the top and bottom of the near beam end, and bolt holes are reserved at the four corners of the special steel plate, and then four long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com