Processing method for sealing failure of 19-inch normal-pressure knife cylinder gate

A technology of sealing failure and treatment method, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of tool wear, slag inclusion in the gate gap, and high cost, and achieve the effect of high safety guarantee and widening adaptation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

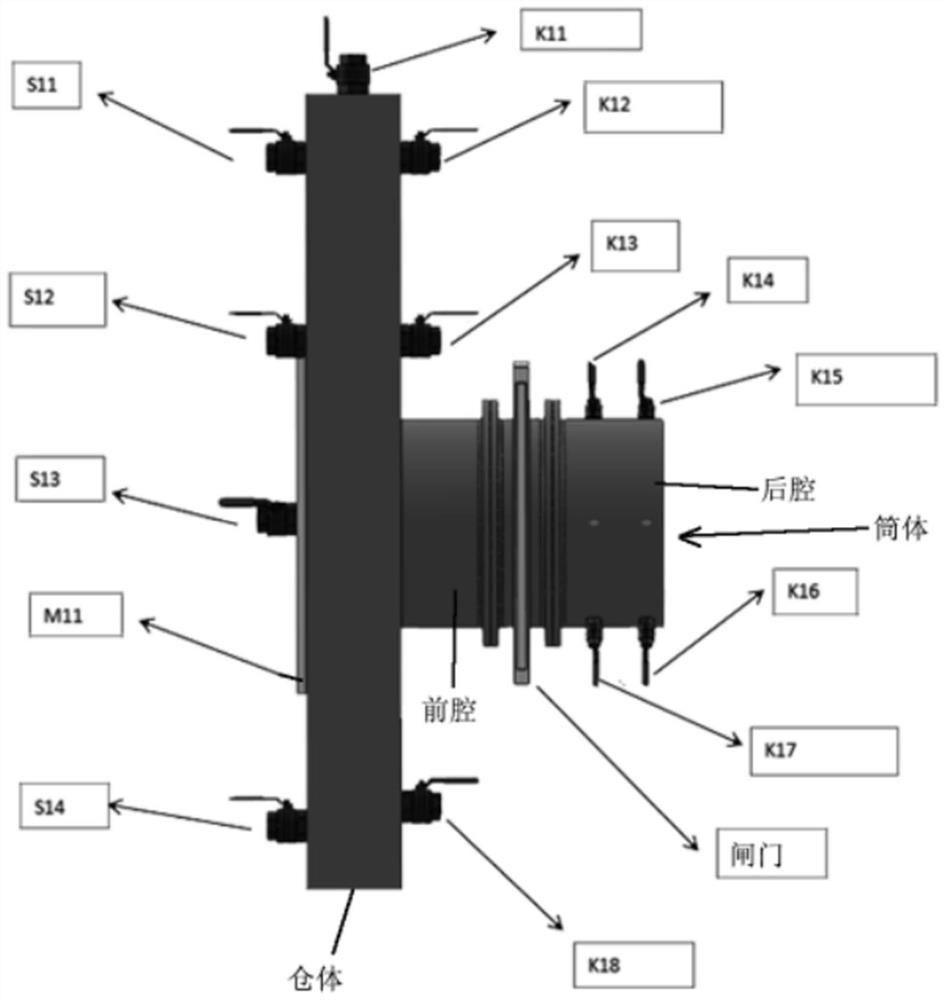

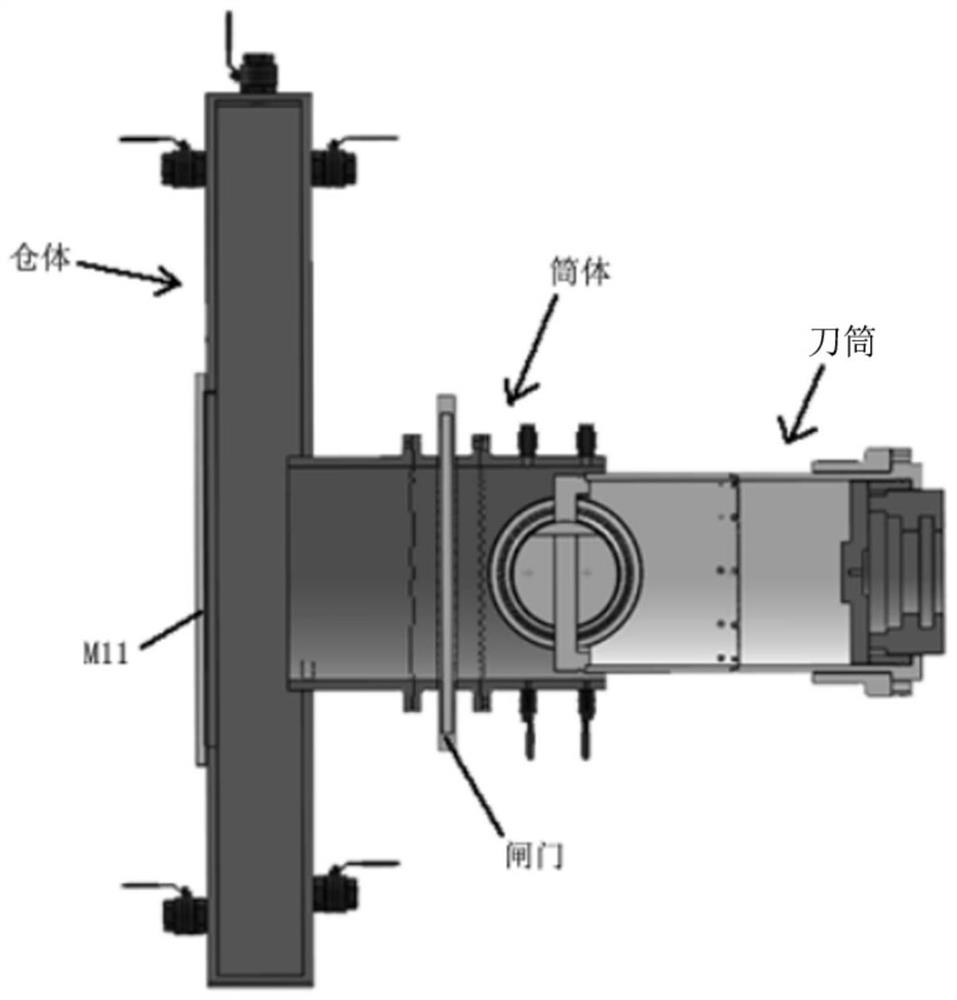

[0037] Such as figure 1 As shown, the cutter gate structure of the present embodiment includes a wall body of the palm mask with a sealing plate M11, a barrel in which a bunter is inserted, a gate, wherein the gate is divided into the tubular cavity of the cylinder into the prodrug. And the rear cavity.

[0038] In this example, during the normal pressure tool change process, after the gate is closed, the slider is pressed, and when the gate is sealed, it is found that the pressure relief requirement cannot be reached, and the shutter seal has leakage (can also be referred to as a sealed failure), Causes that cannot be relieved, the tool cartridge does not pull out, at this time, it must be handled in time to ensure smooth change.

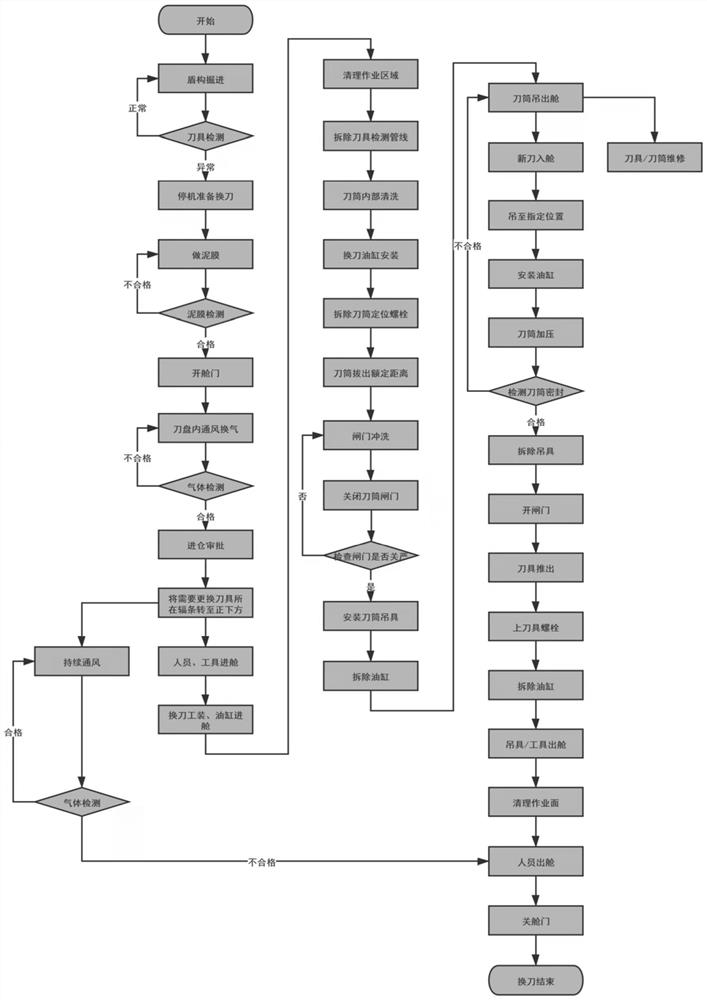

[0039] Specifically, the 19-inch retaining tool is closed, including the following steps: S1, gate leakage; S2, gate failure blockage; S3, tool mounting; S4, replace the gate.

[0040] Process combination figure 2 and image 3 The shown is implemented a...

Embodiment 2

[0047] During the tool change process, the tool is unplugged, and it is found that the gate seal is not allowed to leak. At this time, the person cannot stay in the warehouse, and the personnel need to evacuate, close the center warehouse door, the center bin pressure, ensure pressure balance, The palm is stabilized, and the person is pressed to connect the polyurethane pipe.

[0048] At the same time, the experimental step in this example is basically the same as that of Example 1.

[0049] It is to be further illustrated that the personnel are pressed into the central bin, remove the knife bone plate, connect the polyurethane injection tube, inject the polyurethane, and the injection process, keep the gate to leave a certain slit, continue to leave water, while meeting the normal pressure conditions Next, replace the gate, and to verify this method of adaptability, it also uses 4BAR, 6BAR, 8BAR, and 10BAR pressures, respectively, in the case of blocking experiments.

[0050] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com