Manufacturing method of damping backing of ultrasonic probe

A technology of an ultrasonic probe and a manufacturing method, which is applied in the direction of material analysis, measurement device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problems of low controllability of sound absorption parameters, reduced attenuation effect, and difficult process control, etc. Reduced effects of process instabilities, reduced backing thickness, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The invention aims to solve the problem of uncontrollable sound-absorbing frequency and bandwidth of the damping backing of the ultrasonic probe and the problem of poor damping effect, and proposes a manufacturing method of the damping backing of the ultrasonic probe.

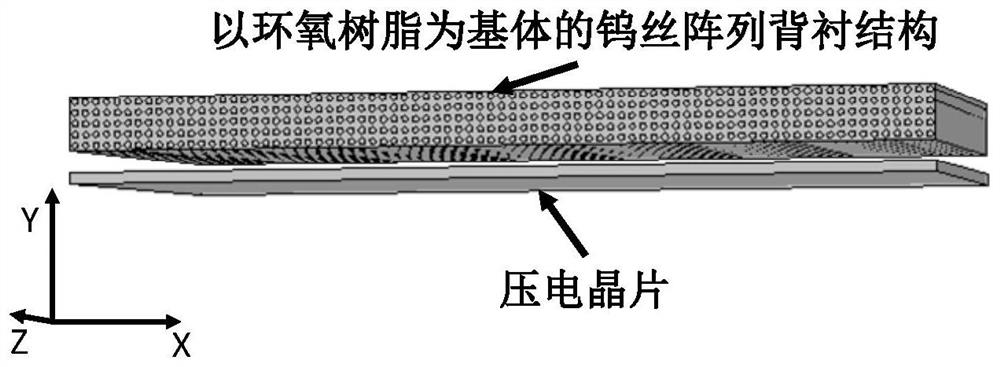

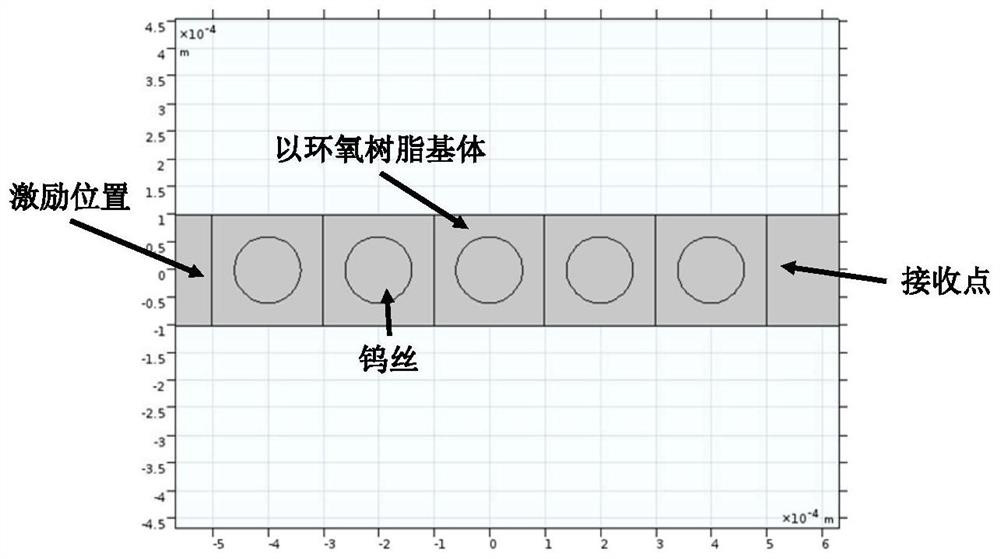

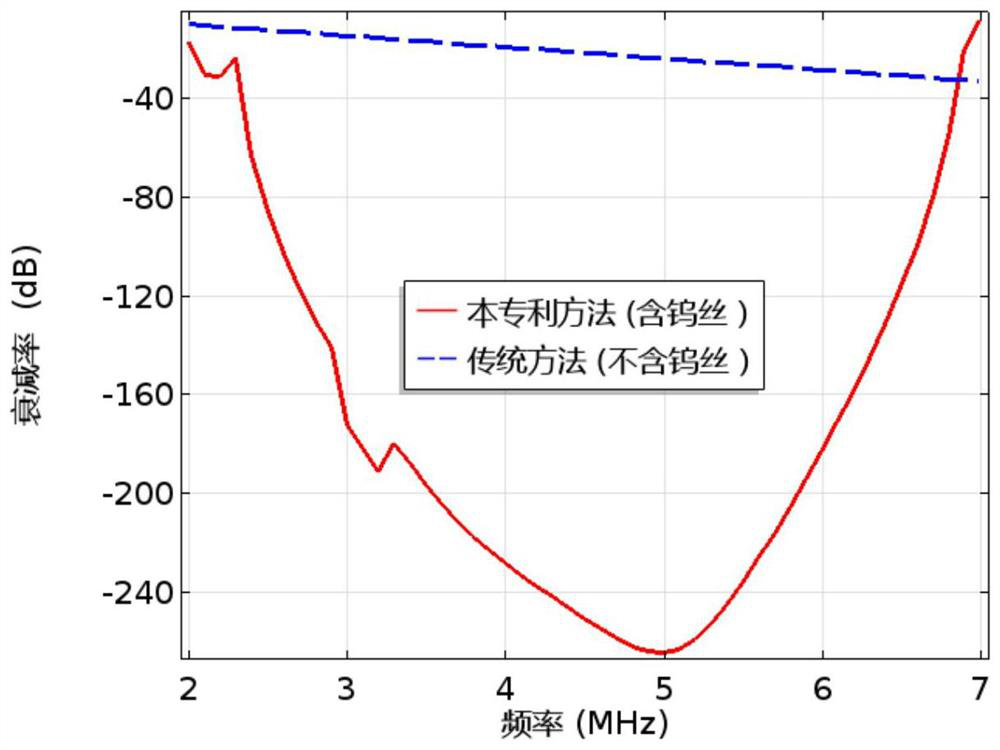

[0035] Taking the commonly used linear array ultrasonic probe with a center frequency of 5 MHz, a bandwidth of 60%, and 32 array elements as an example, its size is 16 mm×10 mm. Taking tungsten wire as an example, according to the formula (1), the distance a=0.2mm is calculated, and the diameter of the tungsten wire d≥0.112mm. In this embodiment, the diameter d is taken as 0.12mm, and the thickness of the backing is taken as 5 times the distance, that is, 1mm . The resulting backing and its installation on the piezoelectric chip are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com