Double-layer packaging substrate alignment method suitable for laser through hole

A packaging substrate and reference technology, applied in the direction of multilayer circuit manufacturing, electrical connection formation of printed components, etc., can solve the problems of inability to meet high-precision wiring design, reduce the company's cash flow, increase the company's operating burden, etc., to reduce input costs, Meet the design requirements and improve the effect of enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Example: such as Figure 1-11 As shown, a double-layer packaging substrate alignment method suitable for laser vias includes the following steps:

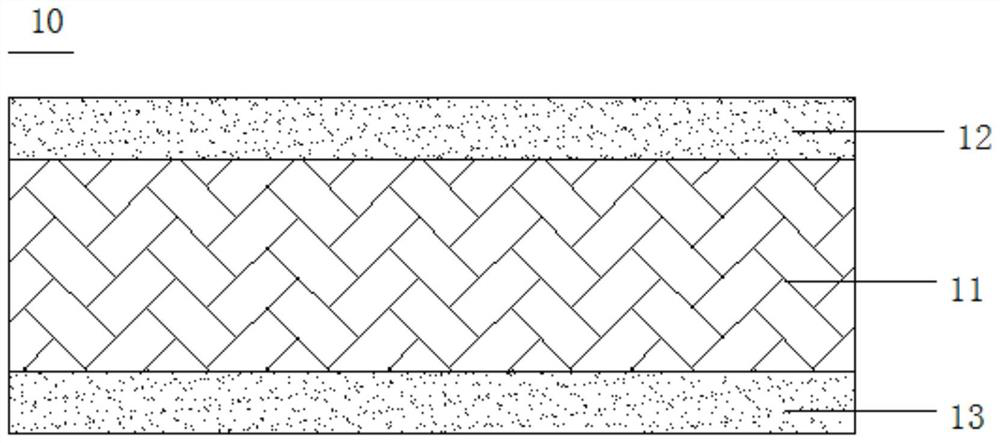

[0048] Step 1: cutting material: such as figure 1 As shown, a substrate 10 of a certain size is cut, and the substrate has a core layer 11 and a first inner copper foil layer 12 and a second inner copper foil layer 13 respectively arranged on the front and back sides of the core layer;

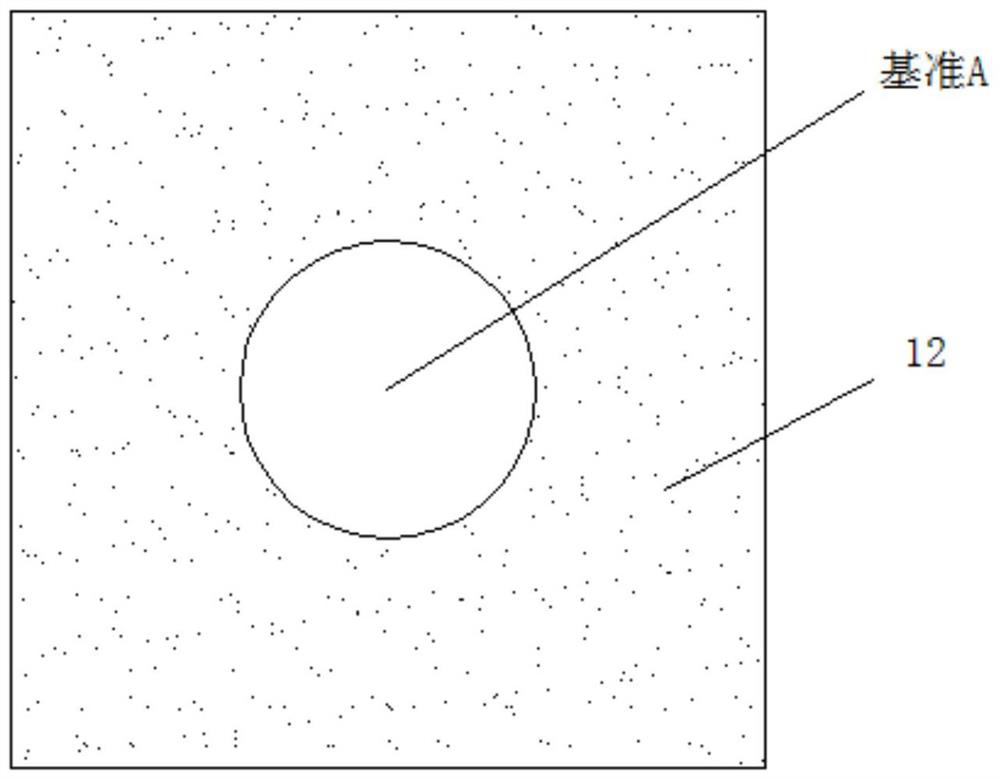

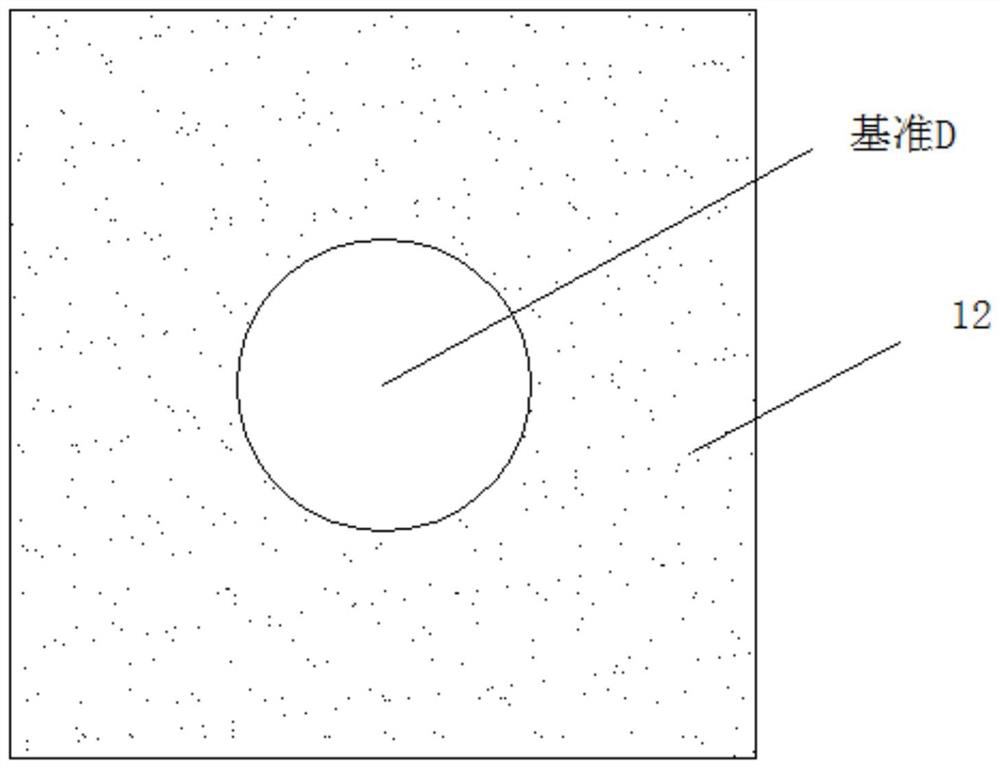

[0049] Step 2: Mechanical drilling: eg figure 2 and image 3 As shown, using mechanical drilling to make the pre-laser line alignment reference A and the graphic line alignment reference D on the edge of the substrate;

[0050] Step 3: Pre-laser circuit: Based on A, make laser drilling alignment reference B, laser hole opening and line alignment reference C window opening; Figure 4 and Figure 5 shows the windowing of the line-to-bit reference C, Figure 6 Alignment datum B is shown;

[0051] Step 4: Laser drilling: Based on B, make l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com