Automatic control system and control method for paint production line of radiator for transformer

An automatic control system and transformer technology, applied in transformer/inductor cooling, inductor/transformer/magnet manufacturing, paint spray booth, etc., can solve the problems of fan operation that cannot be controlled as required, each module cannot be independently controlled, and improve fan life. , to achieve the effect of reducing noise pollution, preventing pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

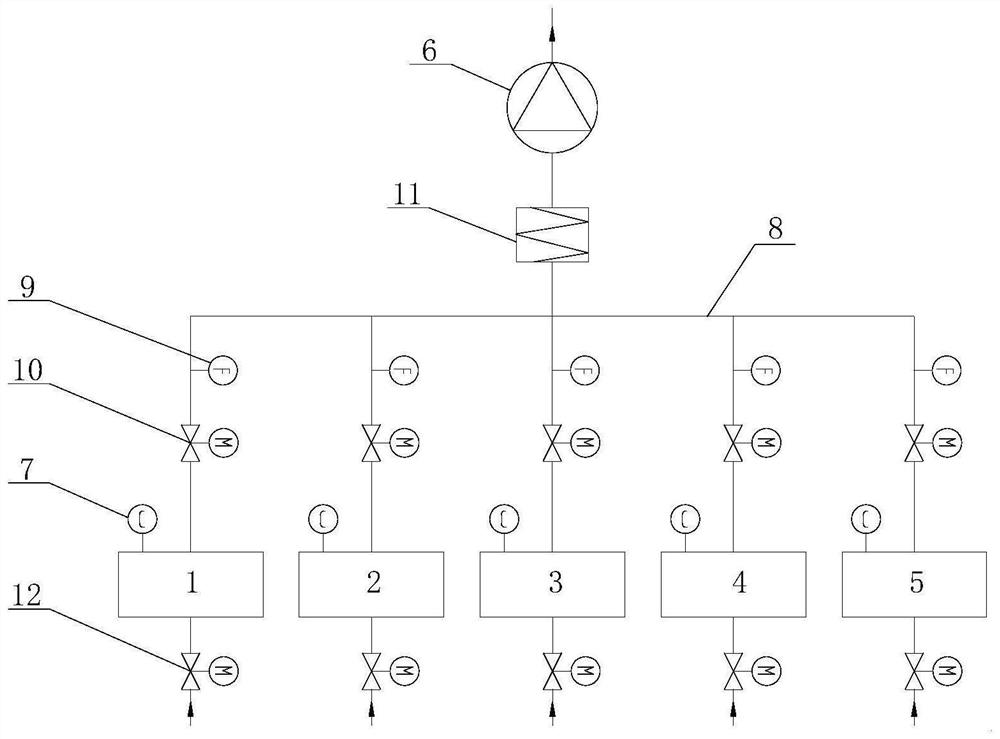

[0027] In this embodiment, the A electric valve 10 is an electric regulating valve. At this time, the electric valve A 10 can be adjusted to change the air volume in the corresponding exhaust duct 8; during the paint spraying process, the exhaust duct 8 of each module can be controlled by using the electric valve A 10 in conjunction with the intelligent fan 6. The precise control of the air volume inside further improves the exhaust effect, and can reduce the number of adjustments to the smart fan 6, further prolonging its service life.

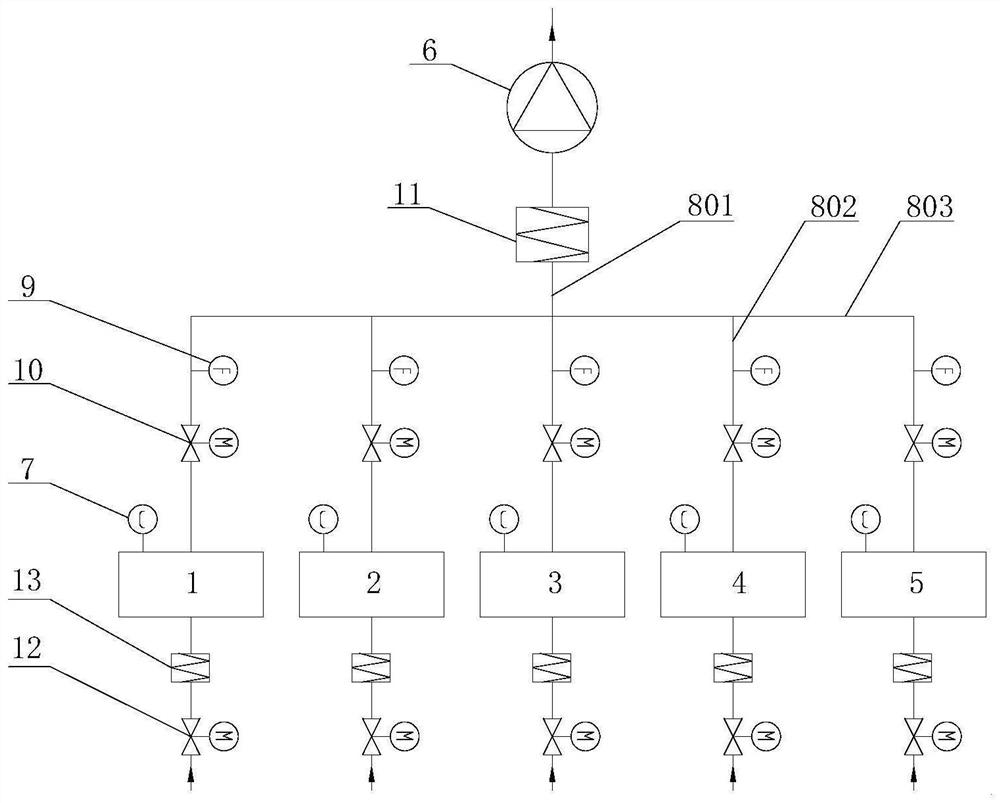

[0028] In this example, see figure 2 , the exhaust duct 8 includes an exhaust main pipe 801, an exhaust branch pipe 802, and a multi-way pipe 803 for connecting the exhaust main pipe 801 and the exhaust branch pipe 802; the air inlet of the smart fan 6 and the exhaust main pipe 801 The air outlet of each module is connected with the corresponding exhaust branch pipe 802, and the air volume transmitter 9 and A electric valve 10 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com