Active feeding and printing mechanism assembly for moving four-side elastic clothes transfer silk screen lamination

A printing mechanism and four-sided printing technology, which is applied to screen printing machines, rotary printing machines, printing machines, etc., to achieve the effect of avoiding premature transportation, taking into account printing efficiency and printing quality, and preventing mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

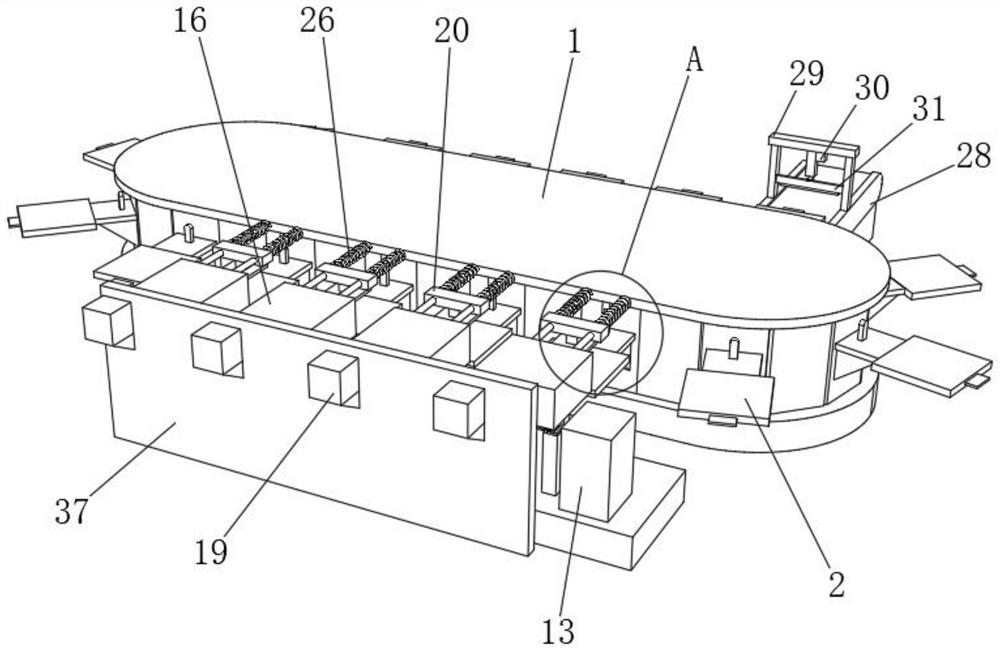

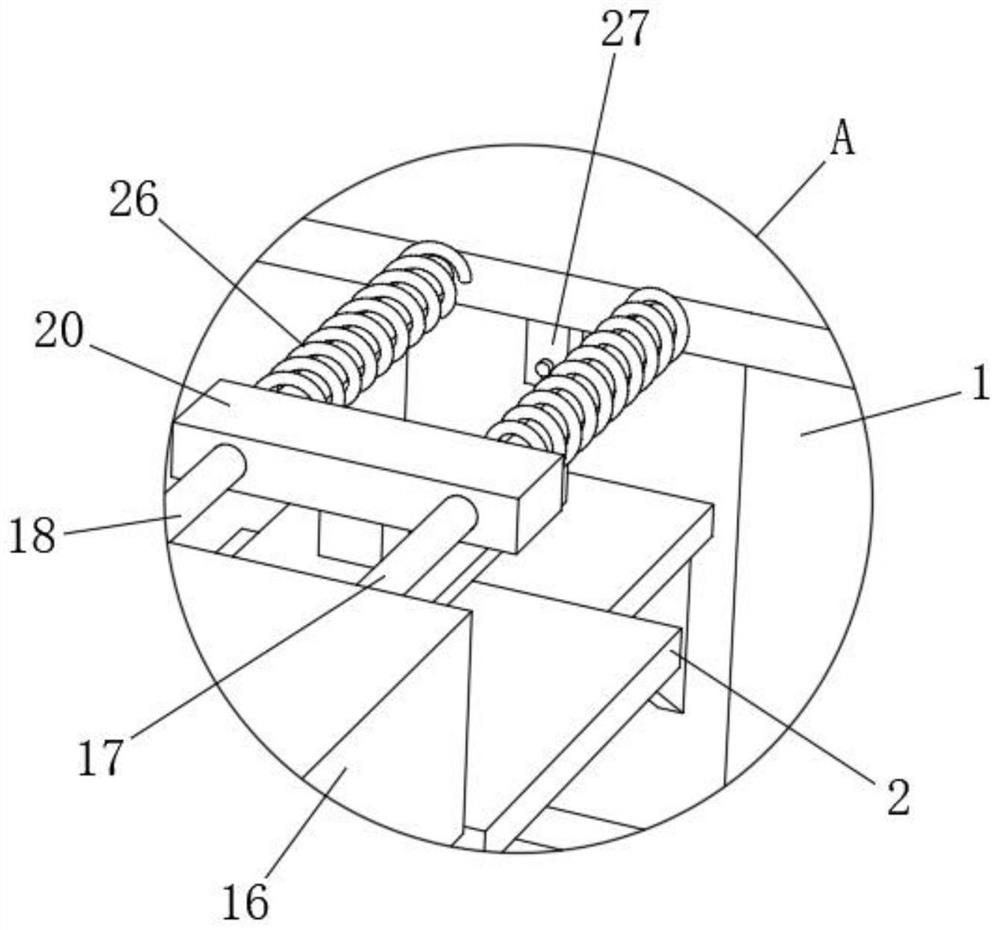

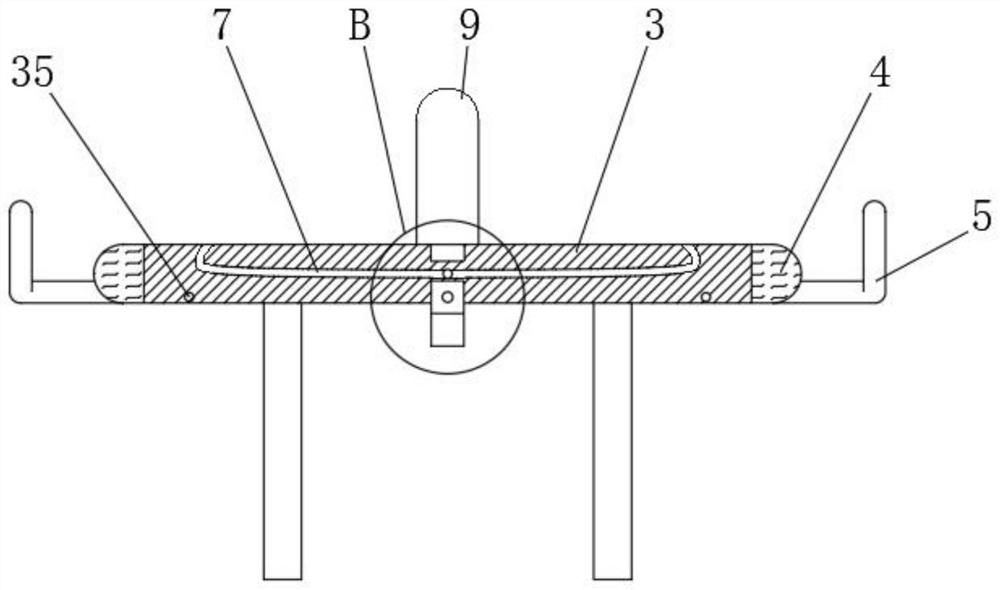

[0032] Such as Figure 1-9 As shown, the embodiment of the present invention provides a sports four-way elastic clothing transfer screen laminated active feeding printing mechanism assembly, including a chain conveyor 1, and the outer side of the chain conveyor 1 is uniformly provided with a bearing assembly 2, and the bearing assembly 2 includes a bearing Plate 3, the left and right ends of the side far away from the chain-plate conveyor 1 are provided with elastic layers 4, and the left and right ends of the side of the load-bearing plate 3 close to the chain-plate conveyor 1 are fixedly connected with curved rods 5. 3 is provided with diversion groove 6 in the middle, diversion groove 7 is evenly arranged on both sides of diversion groove 6, and photosensitive sensor 8 is arranged in the middle of the top of bearing plate 3, and the side of the top of bearing plate 3 close to chain plate conveyor 1 is fixedly connected with The trigger plate 9 is provided with a chute 10 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com