Hollow inner cooling ventilation structure assembly of salient pole motor rotor

A technology of salient pole motors and structural components, applied in the direction of electric components, cooling/ventilation devices, electrical components, etc., to achieve the effects of ensuring continuity, low manufacturing cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

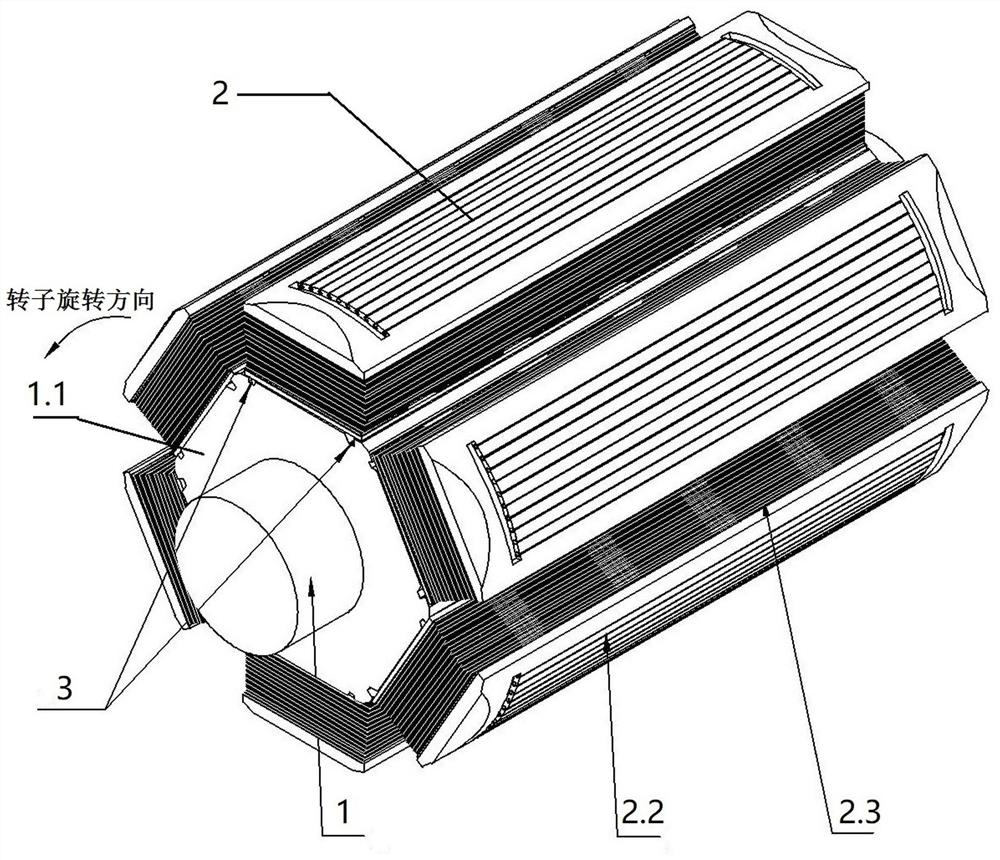

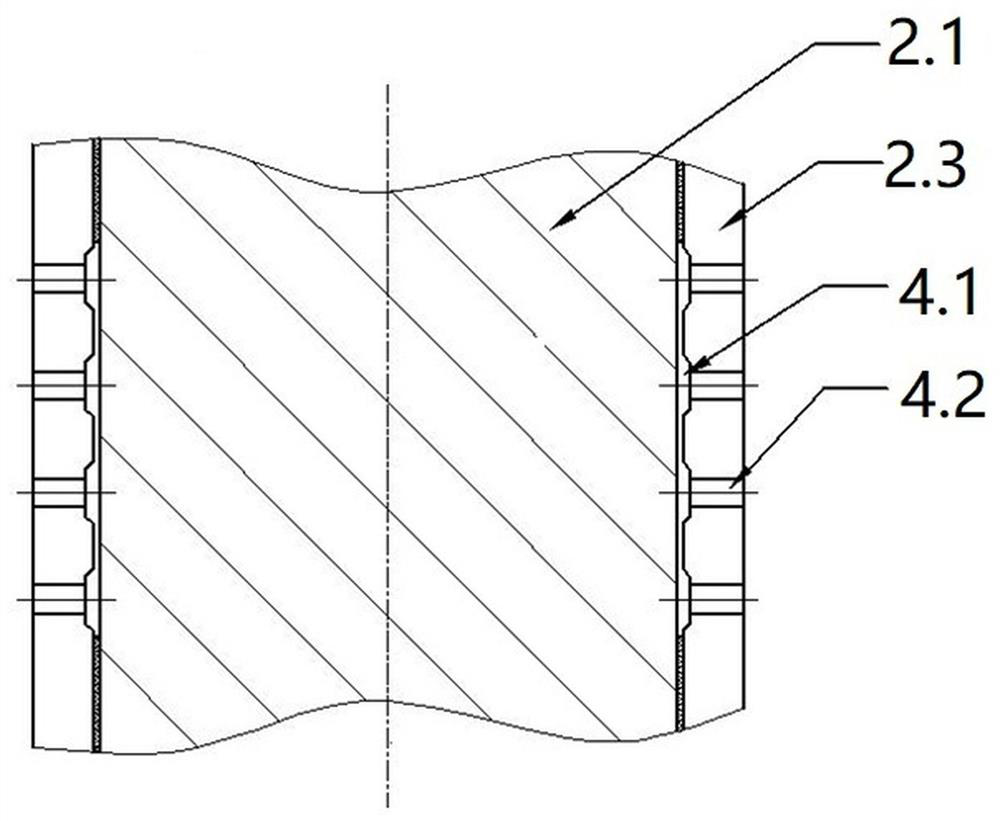

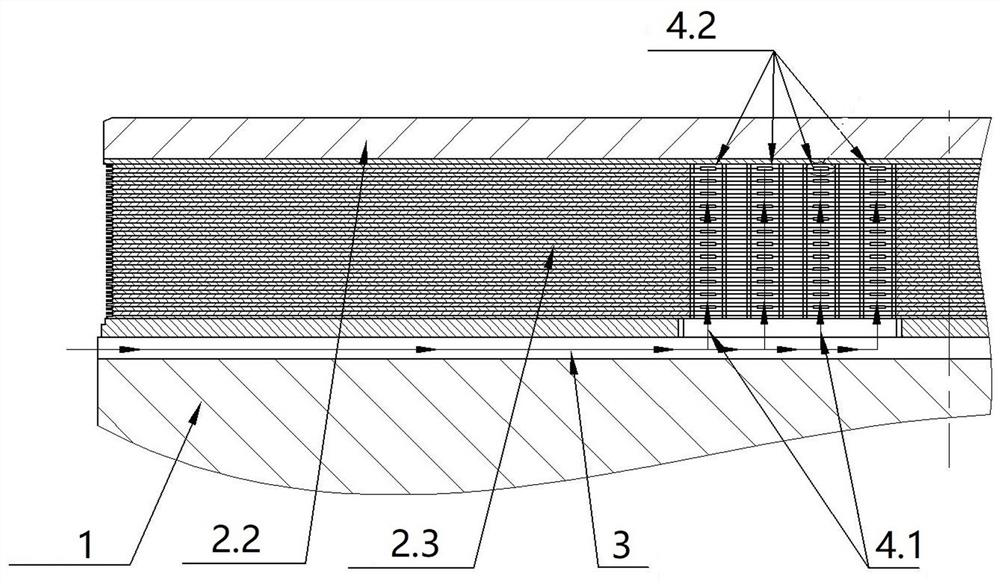

[0034] This embodiment discloses a salient pole motor rotor air internal cooling ventilation structure assembly, including a solid shaft 1 and a magnetic pole unit 2; the solid shaft 1 includes a magnetic pole installation section 1.1, and the magnetic pole installation section 1.1 is in the form of at least four side planes 1.1. 1, a positive prism structure, each side plane 1.1.1 of the magnetic pole installation section 1.1 is respectively provided with a magnetic pole unit 2; the windward side and the leeward side of the magnetic pole unit 2 are parallel to each other, and are respectively perpendicular to the side of the magnetic pole installation section 1.1. Plane 1.1.1, the windward side and the leeward side of the magnetic pole unit 2 are respectively provided with a ventilation system; the magnetic pole unit 2 includes a magnetic pole core 2.1 directly connected to the magnetic pole installation section 1.1, and the magnetic pole core 2.1 is wound with copper as a magn...

Embodiment 2

[0038] This embodiment discloses a salient pole motor rotor air internal cooling ventilation structure assembly, as a preferred implementation of this technical solution, including a solid shaft 1 and a magnetic pole unit 2; the solid shaft 1 includes a magnetic pole installation section 1.1, and the magnetic pole installation section 1.1 is a regular prism structure containing at least four side planes 1.1.1, such as figure 1 and figure 2 As shown, it can include six side planes 1.1.1. Specifically, the number of side planes 1.1.1 of the magnetic pole installation section 1.1 can be increased according to the increase in the radial dimension of the solid shaft 1; each side plane of the magnetic pole installation section 1.1 1.1.1 is respectively provided with a magnetic pole unit 2; the windward side and the leeward side of the magnetic pole unit 2 are parallel to each other, and are respectively perpendicular to the side plane 1.1.1 of the magnetic pole installation section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com