Intelligent grinding equipment capable of screening raw material particles

A granulation and screening technology, applied in grain processing and other directions, can solve the problems of tediousness and low work efficiency, and achieve the effect of improving recovery efficiency, work efficiency and qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

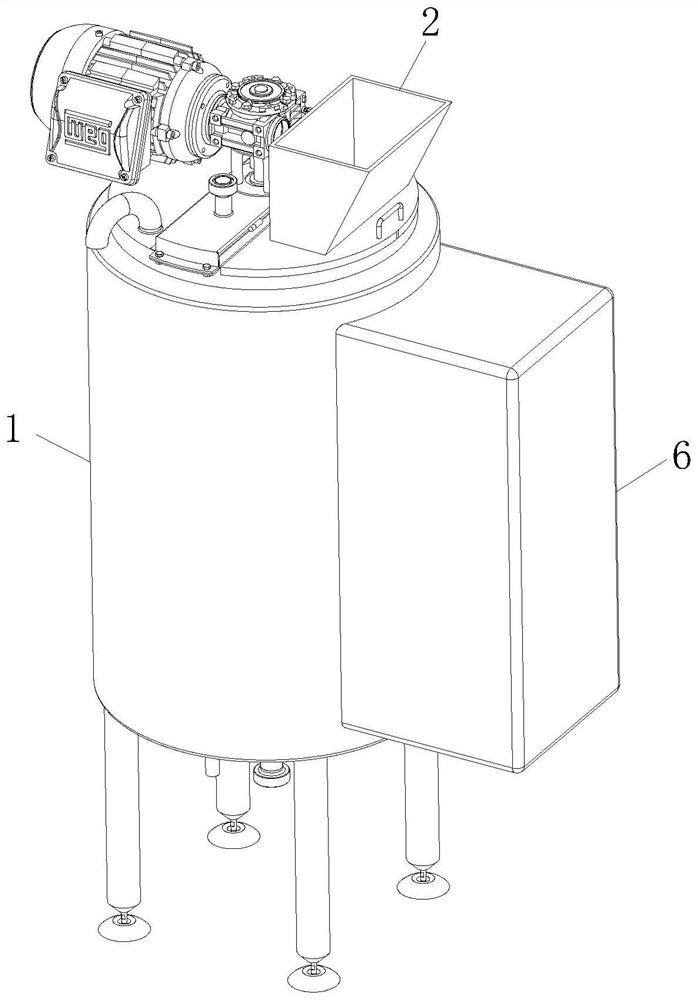

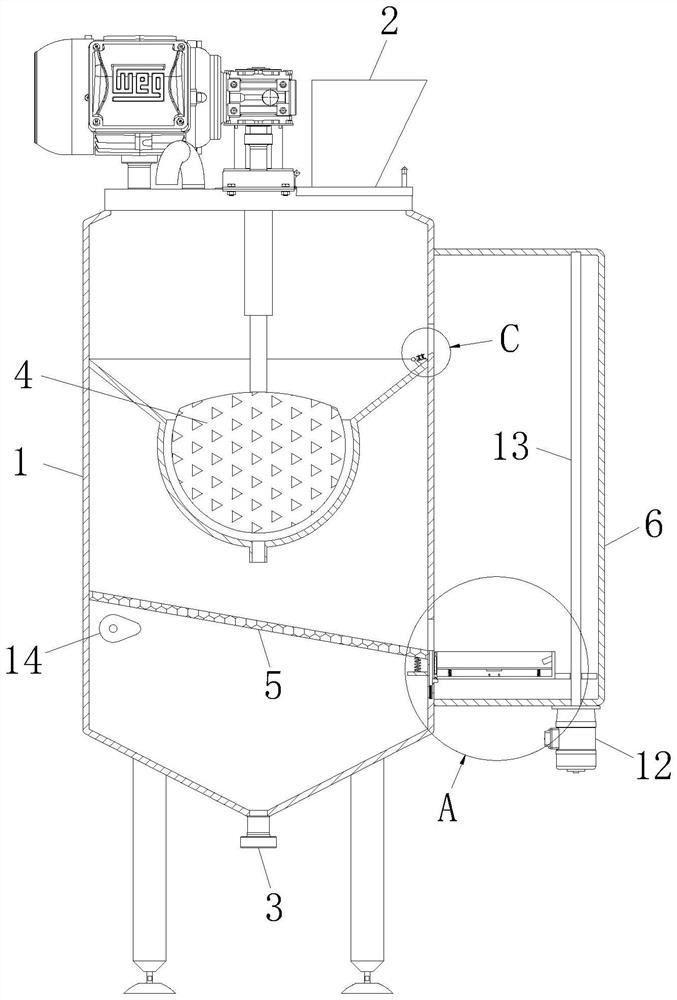

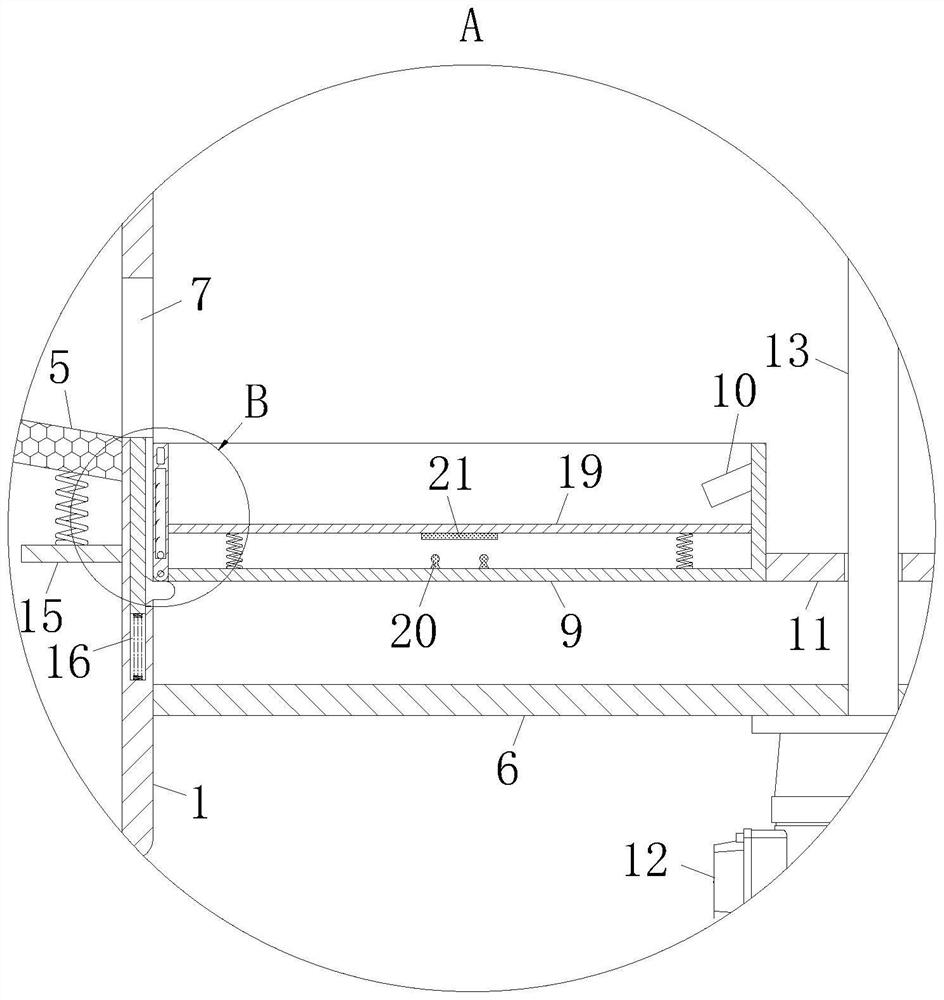

[0030] Such as Figure 1 to Figure 5As shown, an intelligent grinding device capable of screening raw material particles described in the embodiment of the present invention includes a housing 1; the top of the housing 1 is provided with a feed port 2, and the bottom of the housing 1 is provided with a discharge port 3; the inside of the housing 1 is equipped with a grinding unit 4; the inside of the housing 1 below the grinding unit 4 is provided with a screen plate 5, and the screen plate 5 is inclined; one side of the housing 1 is fixed A box body 6 is connected; the side of the housing 1 is provided with a collecting port 7 at a position close to the screen plate 5, and a recovery port 8 is provided at a position close to the grinding unit 4 on the side of the housing 1, and the collecting port 7 and the recovery port 8 are both It communicates with the box body 6; a lifting unit is installed inside the box body 6; a collection box 9 is slidably connected inside the box bo...

Embodiment 2

[0040] Such as Image 6 As shown in Comparative Example 1, another embodiment of the present invention is: the inside of the electronically controlled sprinkler head 10 is rotatably connected with a rotating shaft 32 through a bracket; the outer side of the rotating shaft 32 is fixedly connected with an auger 33; A pair of elastic strips 34 are fixedly connected to one end extending to the outside of the electronically controlled nozzle 10; a small ball 35 is fixedly connected to the end of the elastic strip 34 away from the rotating shaft 32; Rotate, and drive a pair of elastic strips 34 to rotate through the rotating shaft 32, the ball 35 at the end of the elastic strip 34 constantly hits the induction plate 19, driving the induction plate 19 to vibrate, thereby promoting the air flow to take away the materials on the upper side of the induction plate 19, further reducing the The residue of materials on the surface of the induction plate 19 improves the efficiency of materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com