High-frequency wire conductor polishing process

A high-frequency line and conductor technology, applied in the field of high-frequency line conductor polishing technology, can solve the problems of silver-plated conductor appearance scratches and unsatisfactory elongation, and achieve the effect of improving surface polishing efficiency and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] see Figure 1-6 As shown, a high-frequency wire conductor polishing process includes the following steps:

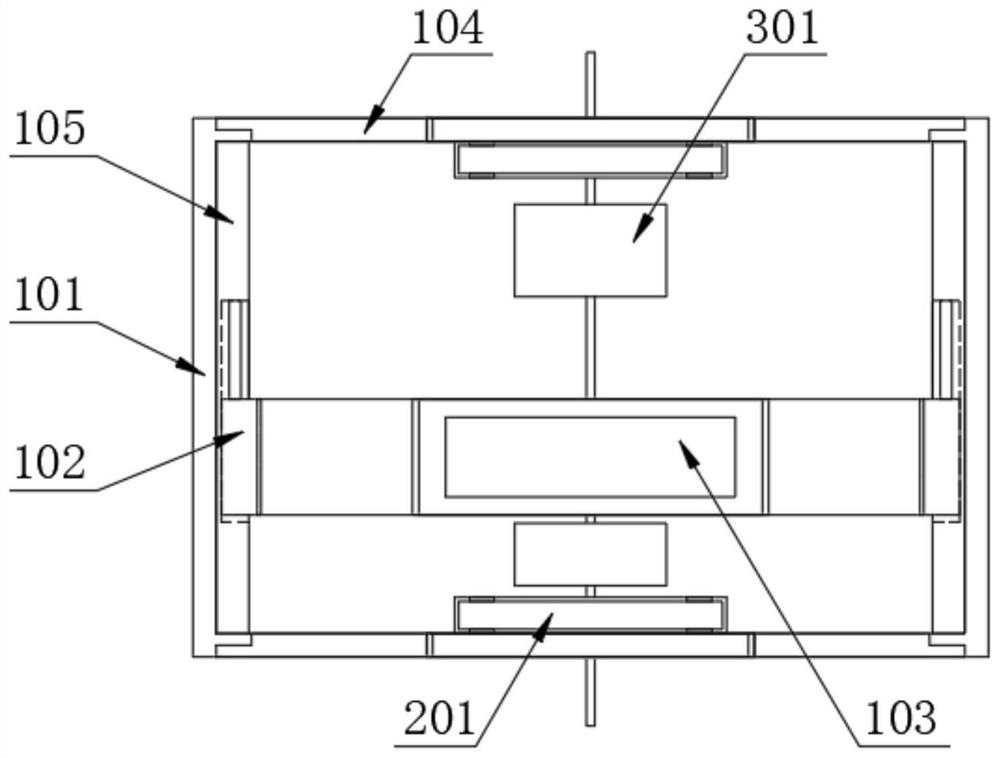

[0033] Step 1. After the annealing section, the high-frequency wire conductor is processed by polishing equipment before the wire is taken up. First, the high-frequency wire conductor is sent into the polishing equipment;

[0034] Step 2, the high-frequency wire conductor is sent into the fixed mount 101 from the movable plate 104 on the top of the fixed mount 101, and one end of the high-frequency wire conductor passes through the cleaning sponge 205 inside the connecting plate 203, and the surface of the high-frequency wire conductor is connected with the cleaning sponge The inner wall of the wire passing hole 206 inside the 205 is in contact, and the impurities on the surface of the high-frequency wire conductor are cleaned by using the cleaning sponge 205;

[0035] Step 3: One end of the high-frequency wire conductor passes through the cleaning sponge 205 and...

Embodiment 2

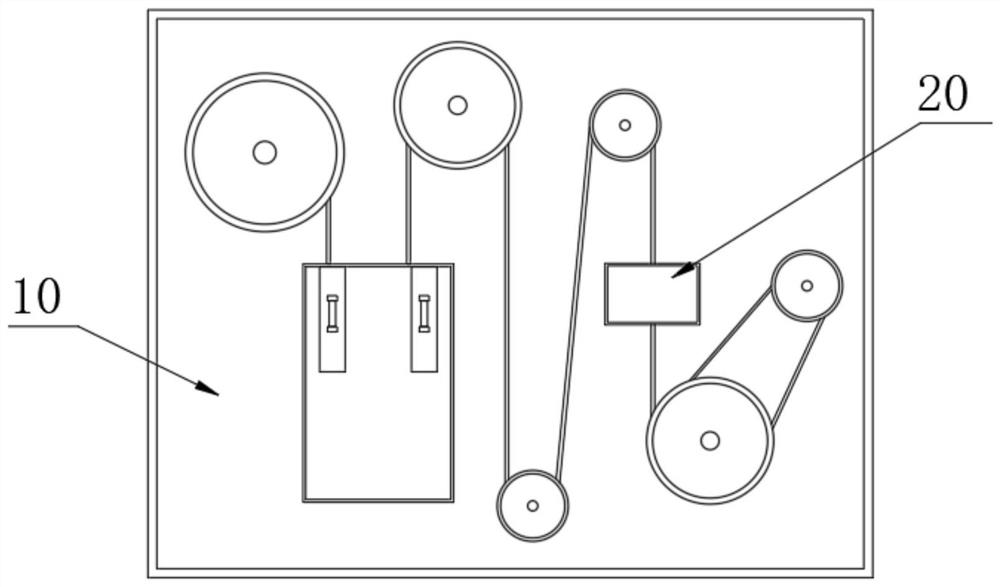

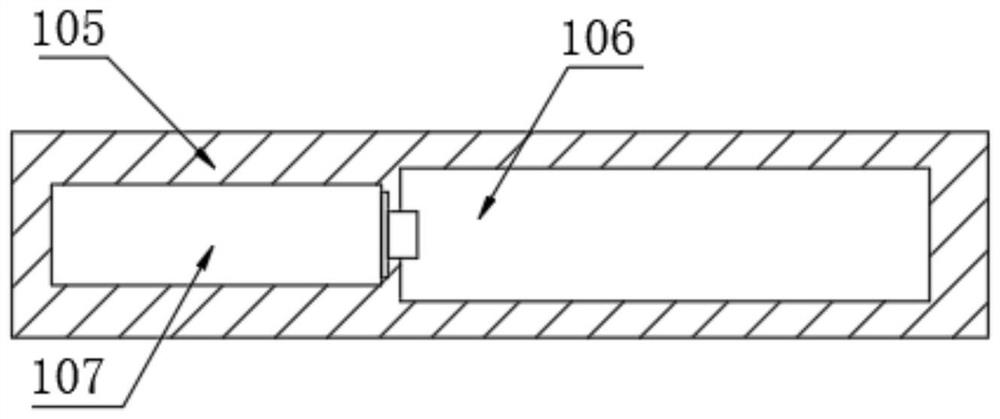

[0038] see Figure 1-3As shown, the polishing equipment includes a frame 10, the front of the frame 10 is provided with a polishing mechanism 20, and the left side of the frame 10 front is provided with an annealing box, the polishing mechanism 20 includes a fixed frame 101, and the back side of the fixed frame 101 is in contact with the machine The front of the frame 10 is fixedly connected, the inside of the fixed frame 101 is provided with a movable frame 102, and the inside of the movable frame 102 is provided with a wire drawing die 103, wherein the wire drawing die 103 adopts a natural diamond mold with a compression ratio of 1-2%, and the fixed frame 101 The top and the bottom are all rotatably provided with movable plates 104, and the opposite sides of the two movable plates 104 are provided with cleaning assemblies, both sides of the fixed mount 101 are provided with slide plates 105, and the insides of the two slide plates 105 are respectively connected with the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com