Electric vehicle low electric quantity working condition high voltage control method based on BMS

A technology for high-voltage control and electric vehicles, applied in electric vehicles, battery/fuel cell control devices, electrical devices, etc., can solve the problems of reduced battery life, inaccurate accuracy, battery damage, etc., to improve driving reliability, Reduce damage and avoid over-discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

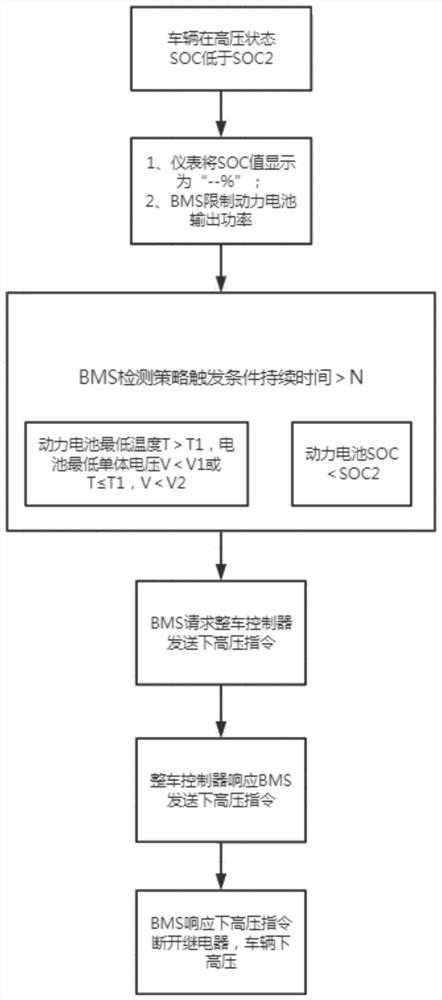

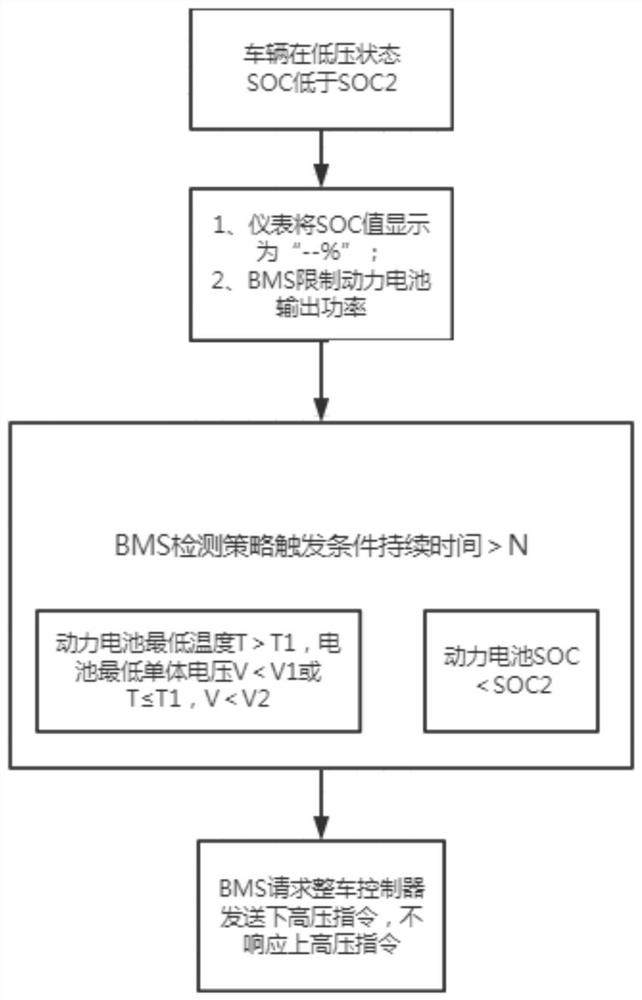

[0030] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0031] The strategy of the present invention aims to solve the problem of poor customer experience caused by the breakdown of the vehicle at the end of discharge of the new energy electric vehicle and to reduce the life loss of the power battery caused by over-discharge.

[0032] When the power of the power battery is low, the battery management system (BMS) will judge whether the current power is exhausted. After triggering the set conditions, the BMS will send a high-voltage request to the vehicle controller to make the vehicle enter a low-voltage state to prevent the vehicle from being depleted due to power consumption. Do not trigger the over-discharge fault of the power battery, which will affect the battery life. At the same time, taking into account the user experience, after the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com