Method for automatically weighing coiled fabric

A roll fabric, automatic weighing technology, applied in the direction of continuous material flow weighing equipment, weighing, conveyor objects, etc., can solve the problems of low efficiency, increased labor intensity, fatigue and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

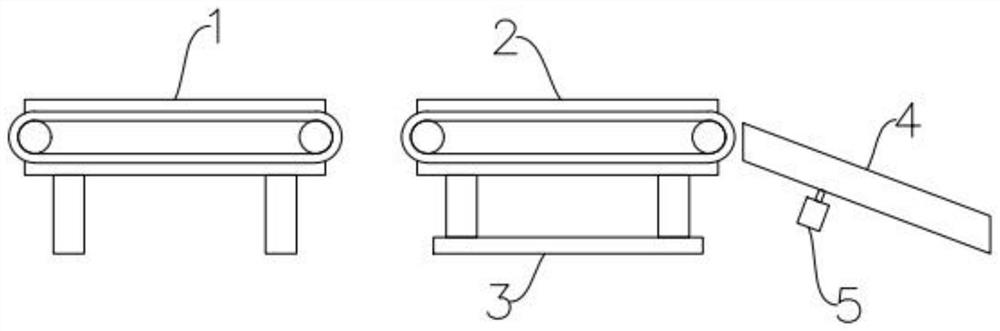

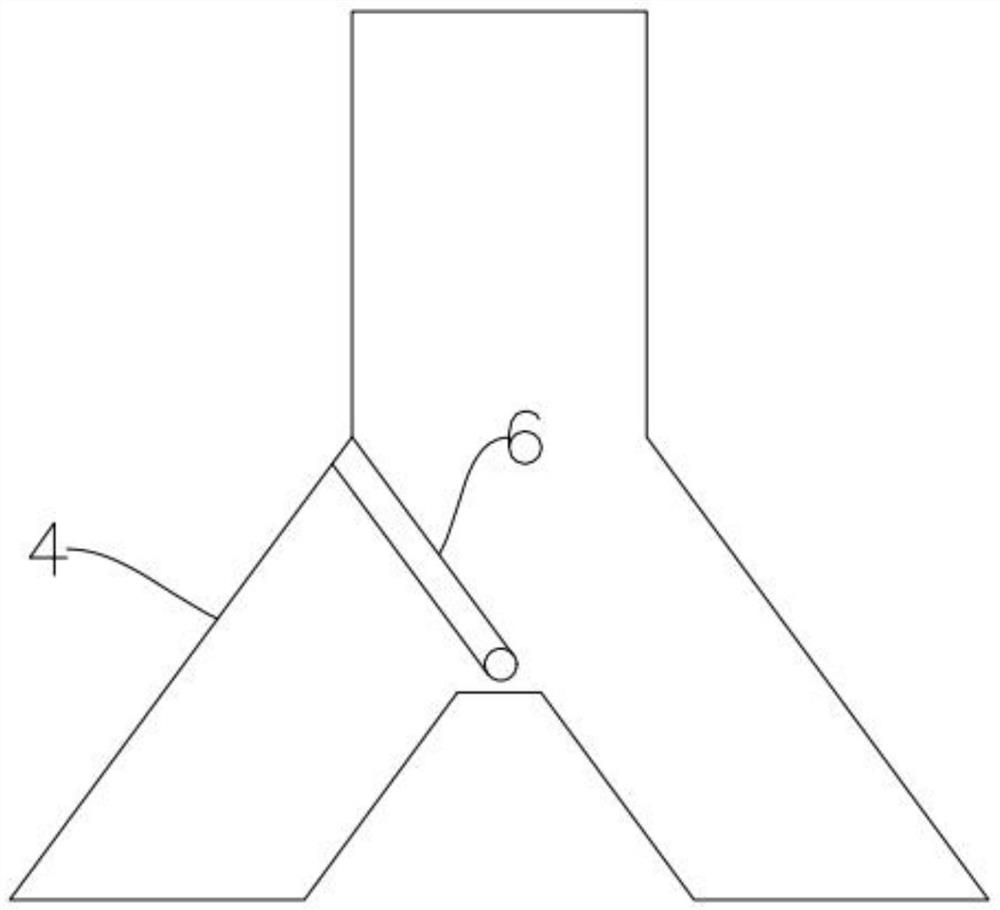

[0039] Such as Figure 1 to Figure 5 As shown, the invention discloses a method for automatic weighing of rolled fabrics, comprising the following steps:

[0040]Step 1, placing the rolled fabric on the conveying platform 1, so that the rolled fabric is placed horizontally on the conveying platform 1, and both ends of the rolled fabric are located on the conveying platform 1, so as to facilitate the transportation of the rolled fabric on the conveying platform 1;

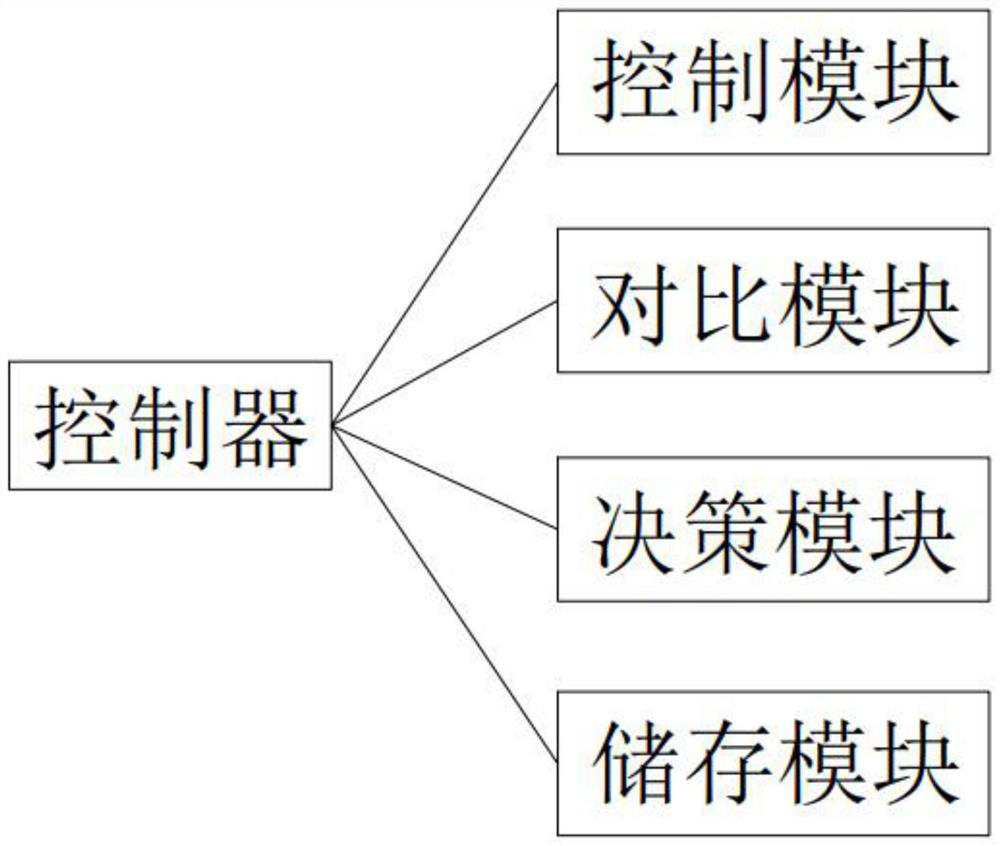

[0041] Step 2, control the work of the conveying platform 1 through the control module in the controller, and transport the rolled fabric to the detection platform 2;

[0042] Step 3, through the weighing platform 3 under the detection platform 2, the weight of the rolled fabric is detected. After the rolled fabric is transported to the detection platform 2, a data value is detected on the weighing platform 3, and this data value is the roll. the weight of the fabric;

[0043] Step 4, after the detection is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com