Elevator steel belt damage dynamic quantitative evaluation device and method

A quantitative evaluation and steel belt technology, applied in the direction of transportation, packaging, elevators, etc., can solve the problems that the damaged parts cannot be calibrated, and the fracture and wear cannot be detected, so as to improve the anti-interference ability and alarm ability of detection, and increase the accuracy of detection The effect of enhancing the degree of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] specific implementation plan

[0046] In order to facilitate a better understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

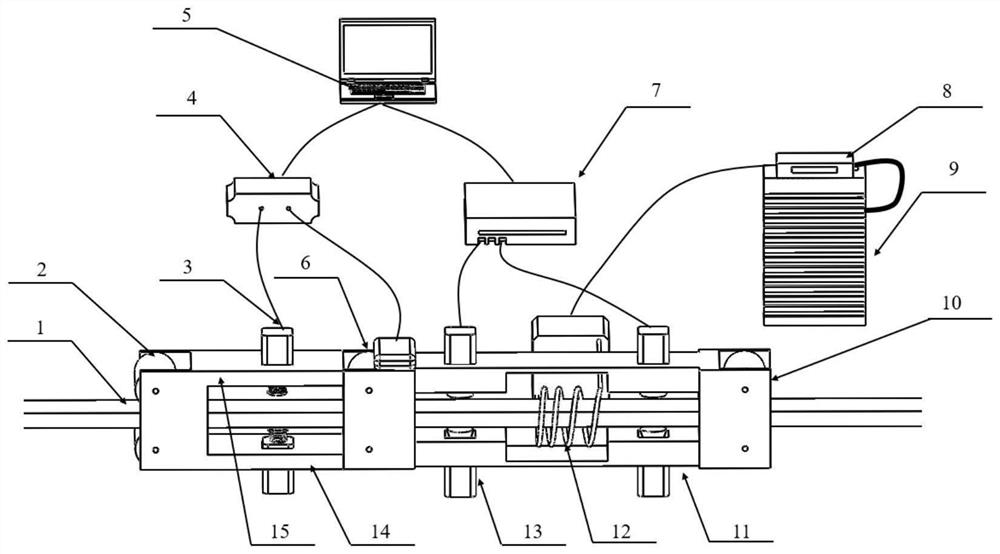

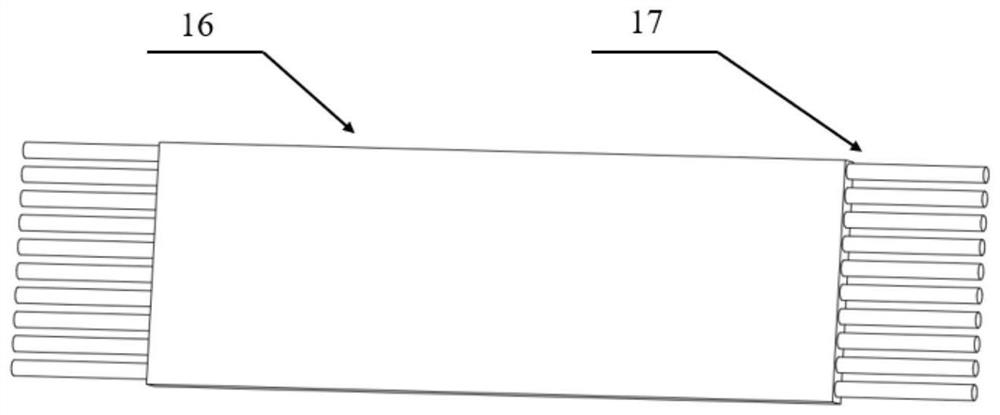

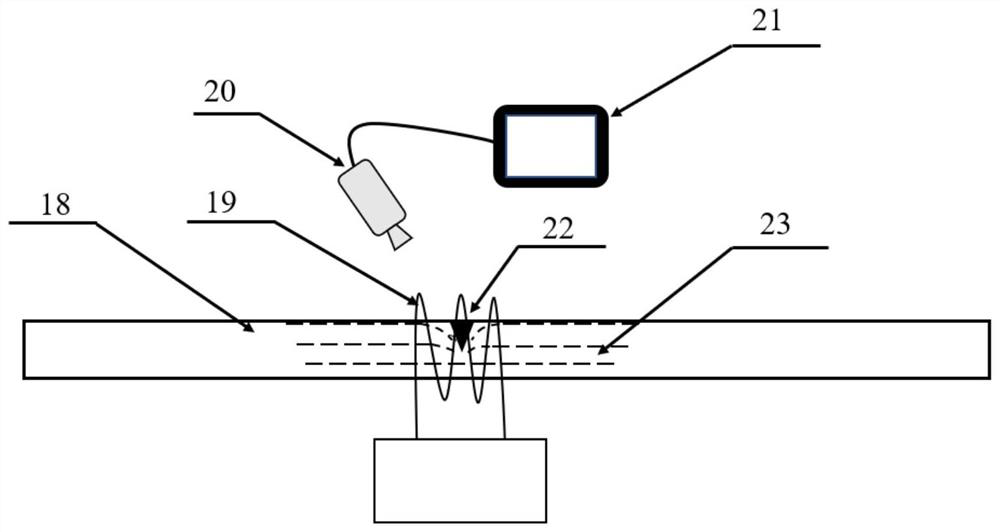

[0047] Please refer to figure 1 , figure 2 and image 3 As shown, the coupling of this device is based on two technologies of industrial high-speed camera and eddy current thermal imaging for comprehensive damage detection of the steel strip 1 to be inspected. The steel strip is mainly divided into two parts: a polyurethane coating layer 13 on the surface of the steel strip and a steel wire rope 14 inside the steel strip. The device includes a steel strip guide wheel assembly, a position detection module 6 , an industrial high-speed camera 3 , infrared thermal imagers 11 and 13 and a high-frequency AC heating system 12 . The following is an introduction to each part:

[0048] The guide wheel assembly, including the front gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com