Preparation method of polyurethane microporous elastomer

A technology of microporous elastomer and polyurethane, which is applied in the field of materials, can solve the problems of limited application, difficulty in meeting the demand for low-temperature compression set performance, poor low-temperature flexibility, etc., and achieve excellent low-temperature flexibility, excellent low-temperature compression set performance, and optimized The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

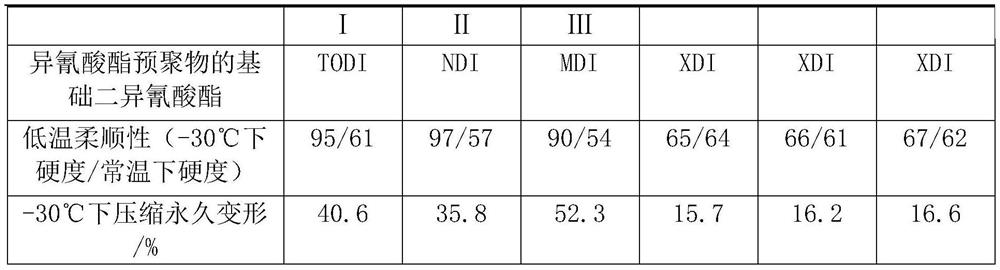

Embodiment 1

[0018] Preparation of prepolymer: After melting 100 parts by weight of PTMEG with a hydroxyl value of 56 mgKOH / g at 80° C., adding 40 parts by weight of XDI, and keeping the temperature for 30 minutes, a clear and transparent polyurethane prepolymer was obtained. Cool to 60°C while stirring to obtain a transparent and clear mixed prepolymer.

[0019] Chain extender preparation: 100 parts by weight of PTMEG with a hydroxyl value of 56mgKOH / g melted at 60°C was added to 5 parts by weight of water, 0.5 parts by weight of a foam stabilizer, and 0.4 parts by weight of a catalyst, and they were stirred and mixed for 2 hours to obtain chain extender.

[0020] Preparation of polyurethane microcellular elastomer finished product: Mix and stir the 80°C prepolymer and 50°C chain extender at a weight ratio of 100:35, and carry out foaming reaction. The reaction time is 30 minutes. After aging, the finished product is obtained for evaluation.

Embodiment 2

[0022] On the basis of Example 1, in the chain extender component, the weight portion of water is reduced to 2.5, and the added glycol is changed from PTMEG to 1,4-butanediol, and its weight portion is 4, and other conditions remain unchanged .

Embodiment 3

[0024] On the basis of Example 1, when the prepolymer was prepared, PCL with a hydroxyl value of 56 mgKOH / g was used, and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com