Method for testing mobility of binder in lithium ion battery pole piece

A lithium-ion battery and testing method technology, which is applied in the field of binder mobility testing in lithium-ion battery pole pieces, can solve problems such as inconvenient binder mobility testing, achieve accurate measurement values, and optimize the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

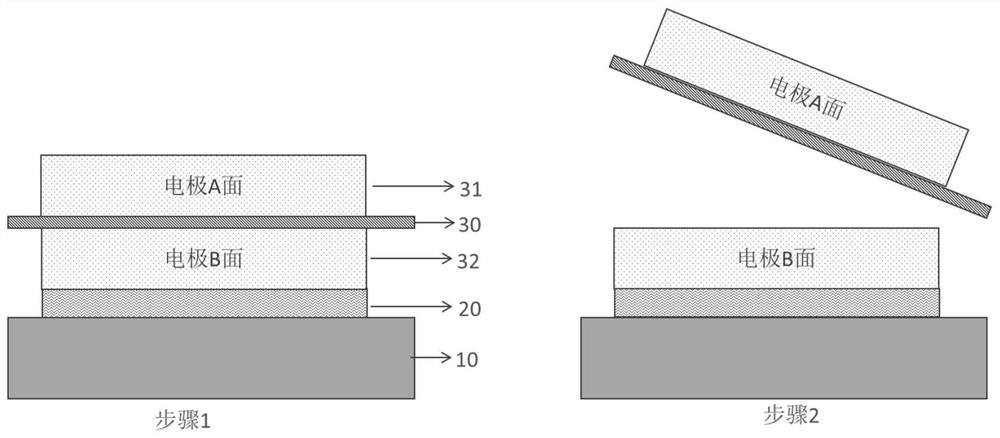

[0025] (1) Electrode preparation and processing: prepare the slurry by mass ratio of graphite negative electrode material: carbon black conductive agent: thickener CMC: binder SBR (A)=94:2:1.5:2.5, and then apply it Spread on copper foil, the coating surface density is 185g m -2 . During the drying process in the oven, the pole piece travels at a speed of 2.5m / min. After rolling the negative electrode once, the compacted density is 1.6g cm -3 . The negative electrode sheet is cut into electrode sheets whose length and width are 5 cm and 8 cm, respectively. Such as figure 1 As shown, the electrode sheet includes two active material layers A-side 31 and B-side 32, and an electrode sheet current collector 30 is arranged between the two active material layers.

[0026] (2) Binder mobility test in battery pole piece:

[0027] S1 Stick one side of the double-sided adhesive tape 20 on the glass substrate 10, and stick the other side on the active material layer B surface of the...

Embodiment 2

[0031] The difference from Example 1 is that during the drying process in the oven, the electrode piece travels at a speed of 5 m / min, and the MD (sample 2) obtained is 1.33.

Embodiment 3

[0033] The difference from Example 1 is that during the drying process in the oven, the pole piece travels at a speed of 7.5 m / min, and the MD (sample 3) is 1.50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com