Method for controllably precipitating crystal phase of transparent glass ceramics for ultra-wide-band fiber amplifiers

An optical fiber amplifier and glass-ceramic technology, which is applied in the field of crystal phase controllable precipitation of transparent glass-ceramic, can solve problems such as uncontrollable crystal phase precipitation, and achieve the effect of optimizing the preparation process and widening the near-infrared broadband light emission range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

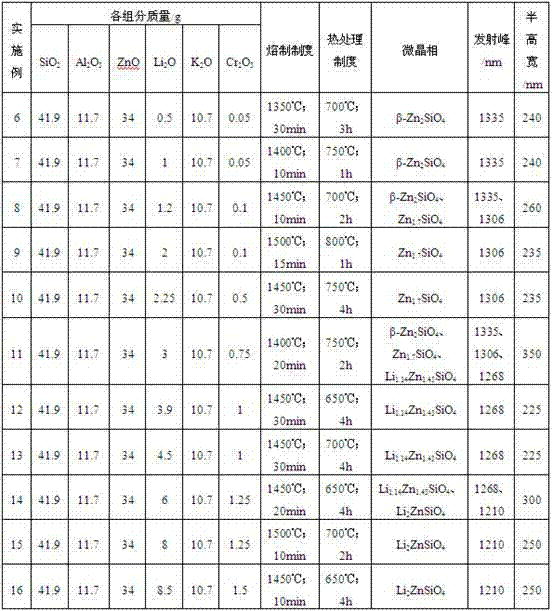

[0022] Weigh 41.9 g of SiO 2 , 11.7g of Al 2 o 3 , 34 g of ZnO, 10.7 g of K 2 O, 0.01 g of Cr 2 o 3 , after mixing the above components evenly, after melting at 1350 °C, keep the temperature for 10 minutes, pour the glass melt into the preheated mold, transfer to the muffle furnace with the temperature of 500 °C for 1 hour, and then close the furnace Furnace, let it cool down to room temperature naturally, get basic glass.

[0023] The basic glass was heat-treated at 650 °C for 4 hours, and then cooled to room temperature to obtain precipitated β-Zn 2 SiO 4 Nanocrystalline glass-ceramics.

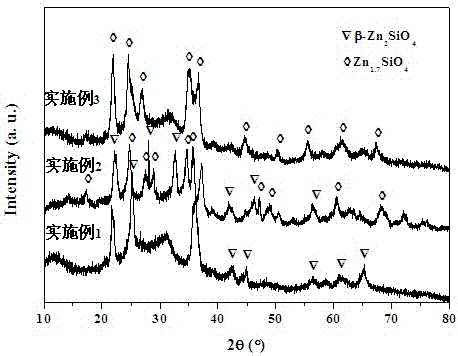

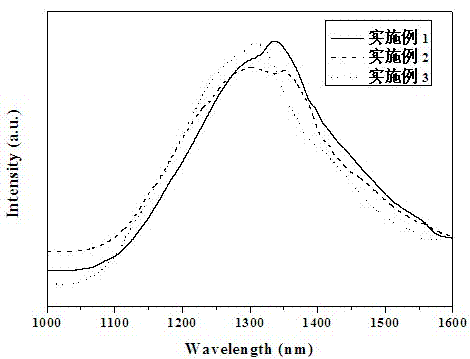

[0024] The XRD pattern of this transparent glass-ceramic is shown in figure 1 , see the fluorescence spectrum figure 2 . Depend on figure 1 It can be obtained that the crystallite crystal phase in the transparent glass-ceramic is β-Zn 2 SiO 4 ;Depend on figure 2 It can be obtained that the emission peak of the glass-ceramics is located at 1335 nm, and the full width at half ...

Embodiment 2

[0026] Weigh 41.9 g of SiO 2 , 11.7g of Al 2 o 3 , 34 g of ZnO, 1.5 g of Li 2 O, 10.7 g of K 2 O, 1.5 g of NiO, mix the above components evenly, melt at 1500 °C, keep warm for 30 minutes, pour the glass melt into a preheated mold, and transfer to a muffle furnace with a temperature of 500 °C to keep warm 1 hour, then close the muffle furnace, let it cool down to room temperature naturally, and obtain the basic glass.

[0027] The base glass was heat-treated at 850 °C for 1 hour, and then cooled to room temperature to obtain precipitated β-Zn 2 SiO 4 and Zn 1.7 SiO 4 Nanocrystalline glass-ceramics.

[0028] The XRD pattern of this transparent glass-ceramic is shown in figure 1 , see the fluorescence spectrum figure 2 . Depend on figure 1 It can be obtained that the crystallite crystal phase in the transparent glass-ceramic is β-Zn 2 SiO 4 , Zn 1.7 SiO 4 ;Depend on figure 2 It can be obtained that the emission peaks of the glass-ceramics are located at 1335 nm...

Embodiment 3

[0030] Weigh 41.9 g of SiO2 , 11.7g of Al 2 o 3 , 34 g of ZnO, 2.5 g of Li 2 O, 10.7 g of K 2 O, 0.5 g of CoO, mix the above components evenly, melt at 1450 °C, keep warm for 15 minutes, pour the glass melt into a preheated mold, transfer to a muffle furnace with a temperature of 500 °C and keep it warm 1 hour, then close the muffle furnace, let it cool down to room temperature naturally, and obtain the basic glass.

[0031] The base glass was heat-treated at 700 °C for 2 hours, and then cooled to room temperature to obtain precipitated Zn 1.7 SiO 4 Nanocrystalline glass-ceramics.

[0032] The XRD pattern of this transparent glass-ceramic is shown in figure 1 , see the fluorescence spectrum figure 2 . Depend on figure 1 It can be obtained that the crystallite crystal phase in the transparent glass-ceramics is Zn 1.7 SiO 4 ;Depend on figure 2 It can be obtained that the emission peak of the glass-ceramics is located at 1306 nm, and the full width at half maximum i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com