Finishing equipment for glass fiber stitch-bonded felt

A technology of glass fiber and stitch-bonded mat, which is applied in the field of stitch-bonded mat processing, which can solve problems such as difficulty in finishing and using glass fiber stitch-bonded mat, reduce work efficiency, etc., achieve standardized winding operations, improve practicability, and facilitate finishing The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

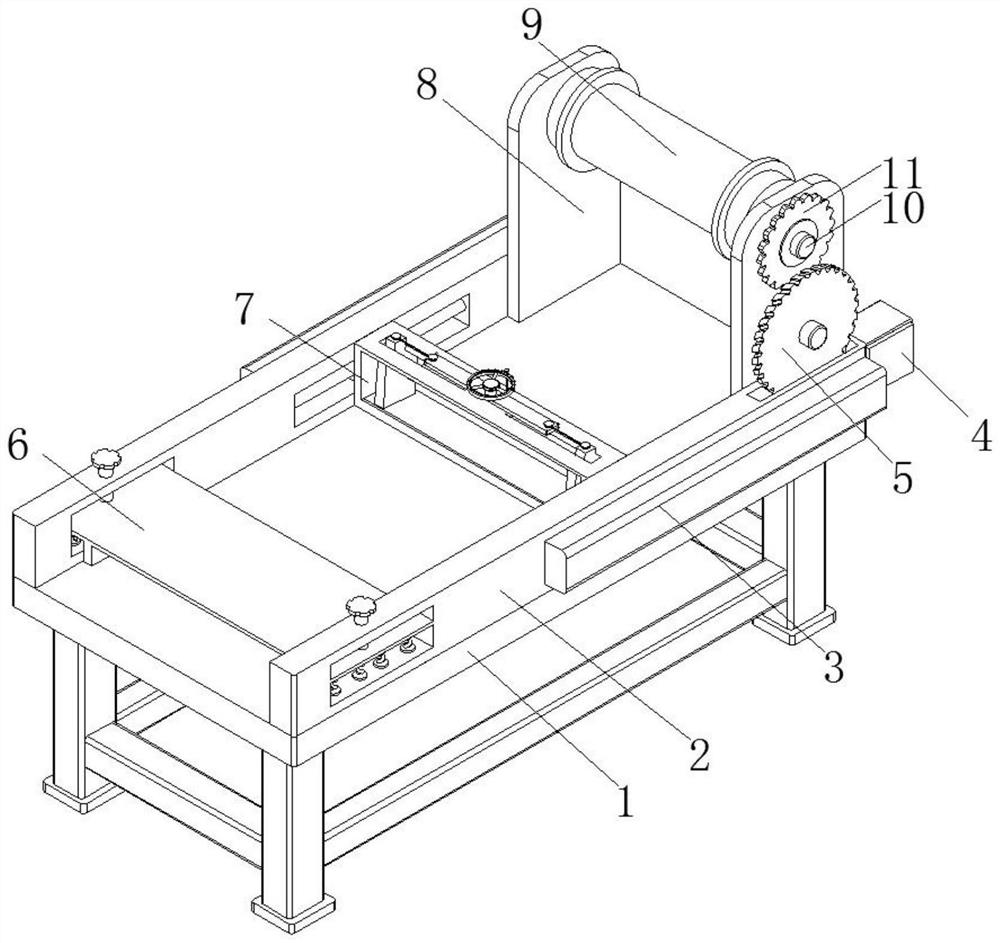

[0037] Such as Figure 1-6As shown, the present invention provides a technical solution: a sorting device for glass fiber stitched felt, including a workbench 1 and legs fixed at the bottom of the workbench 1 for support, and the top of the workbench 1 is fixed There are two left-right symmetrical fences 2, and the two fences 2 are respectively located along the edge of the workbench 1, and the length of the fences 2 is consistent with the length of the workbench 1, and the opposite boards of the two fences 2 There are frame boards 8 fixed on the surface, and the two frame boards 8 are attached and fixed to the fence board 2 respectively, and the same winding assembly 9 pairs of glass fiber stitching mats are arranged on the opposite board surfaces of the two frame boards 8 For winding and sorting, there is an opening on the board body of the two fences 2, and the size of the opening on the left fence 2 is half the size of the opening on the right fence 2, and the opening on t...

Embodiment 2

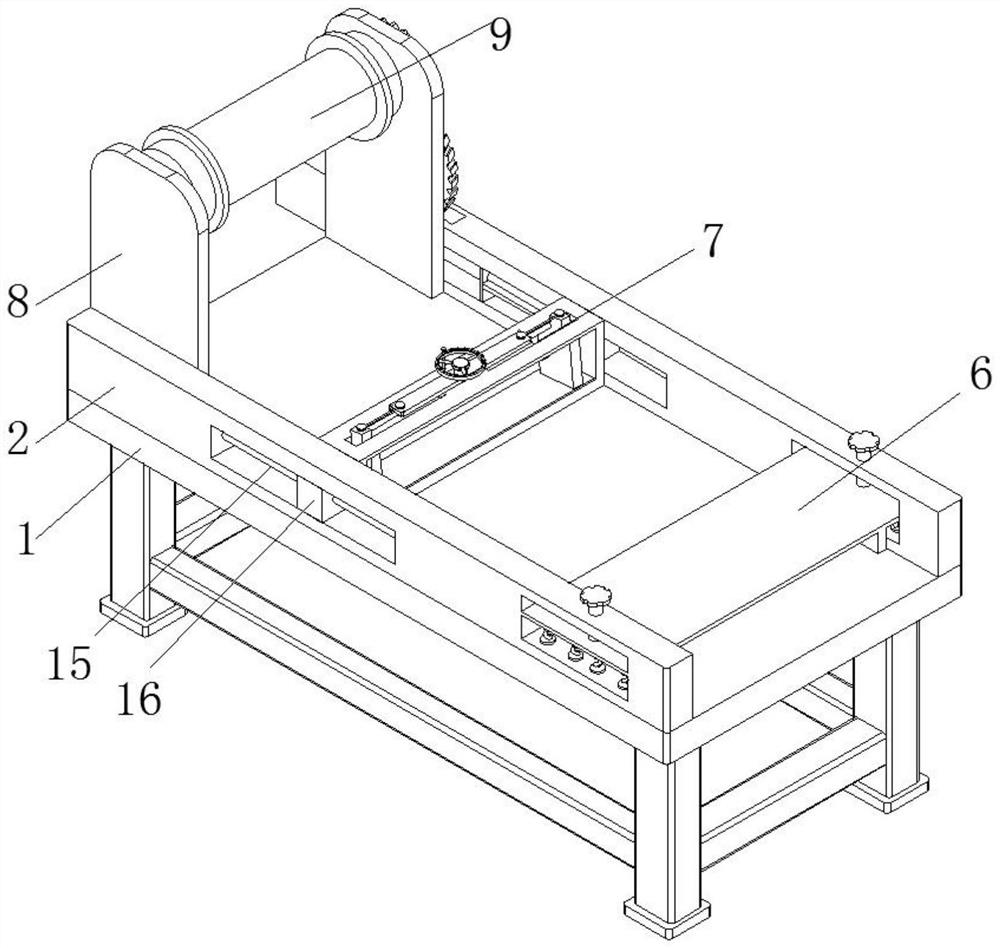

[0041] Such as Figure 7 As shown, this embodiment is basically consistent with Embodiment 1, preferably, and the opposite board surfaces of the two fences 2 are also provided with the same smoothing assembly 6 to smooth the glass fiber stitched mat to be treated to prevent its finishing Front arching, flattening assembly 6 includes internal openings 601 respectively opened on the two sills 2, and some stage clips A602 are all arranged in the two internal ports 601, and the compression springs A602 in each internal port 601 The number is not less than four, and the other ends of several compression springs A602 are fixed with the same horizontal plate 603, and the bottom of the horizontal plate 603 is fixed with two symmetrical legs 604, and the two legs 604 rotate The same roller 605 is installed, and the radial distance between the lowest point of the roller 605 and the lowest point of the frame leg 604 is at least five centimeters to ensure that the roller 605 can be in con...

Embodiment 3

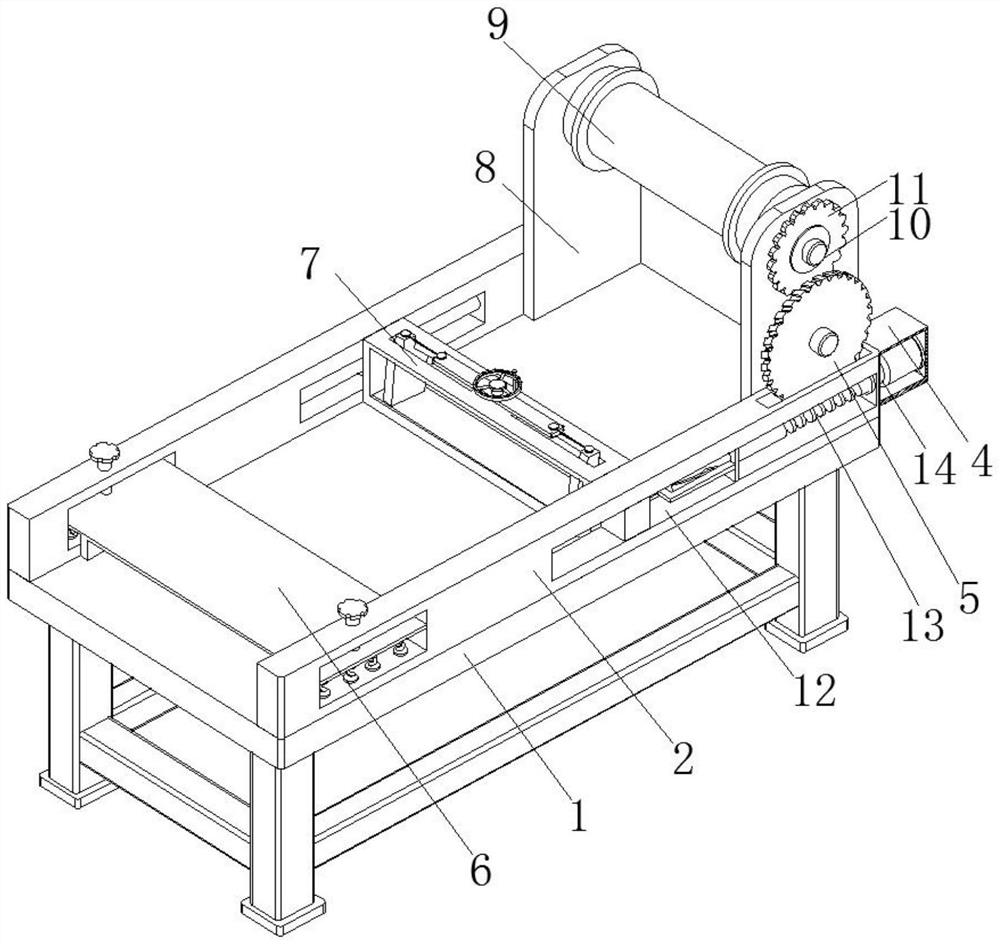

[0044] Such as Figure 5-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a rotating shaft is fixed at the middle position of the top of the rectangular plate 703, and a hand wheel 704 is fixed on the end of the shaft. There are several annular equidistant limiting holes 709, and a through hole with the same diameter as the limiting hole 709 is also arranged on the top of the rectangular frame 701, and a plug is inserted into the through hole and another limiting hole 709 710, to carry out the limit fixation of hand wheel 704 turning.

[0045] In this embodiment, the staff turns the handwheel 704 to make the rectangular plate 703 rotate upwards, thereby pulling the two rectangular plates 703 to move toward or away from each other, so that the scraper 708 on the rectangular plate 703 can accurately Attached to both sides of the glass fiber stitching mat, so as to better meet the deburring work of glass fiber stitching mats of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com