Dismantling method for top conical structure of prilling tower

A technology of conical structure and prilling tower, applied in building construction, building material processing, building maintenance, etc., can solve the problems of difficult operation, splashing of explosives, long construction period, etc., achieve simple demolition process, ensure operation The effect of safety and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

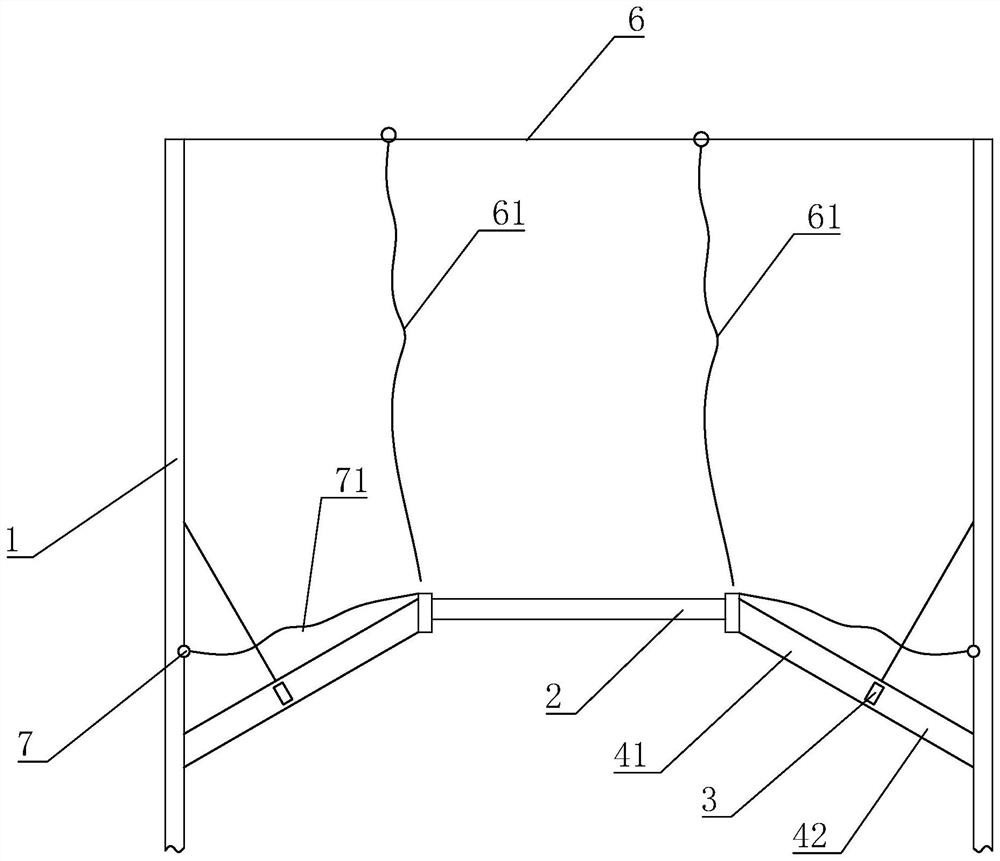

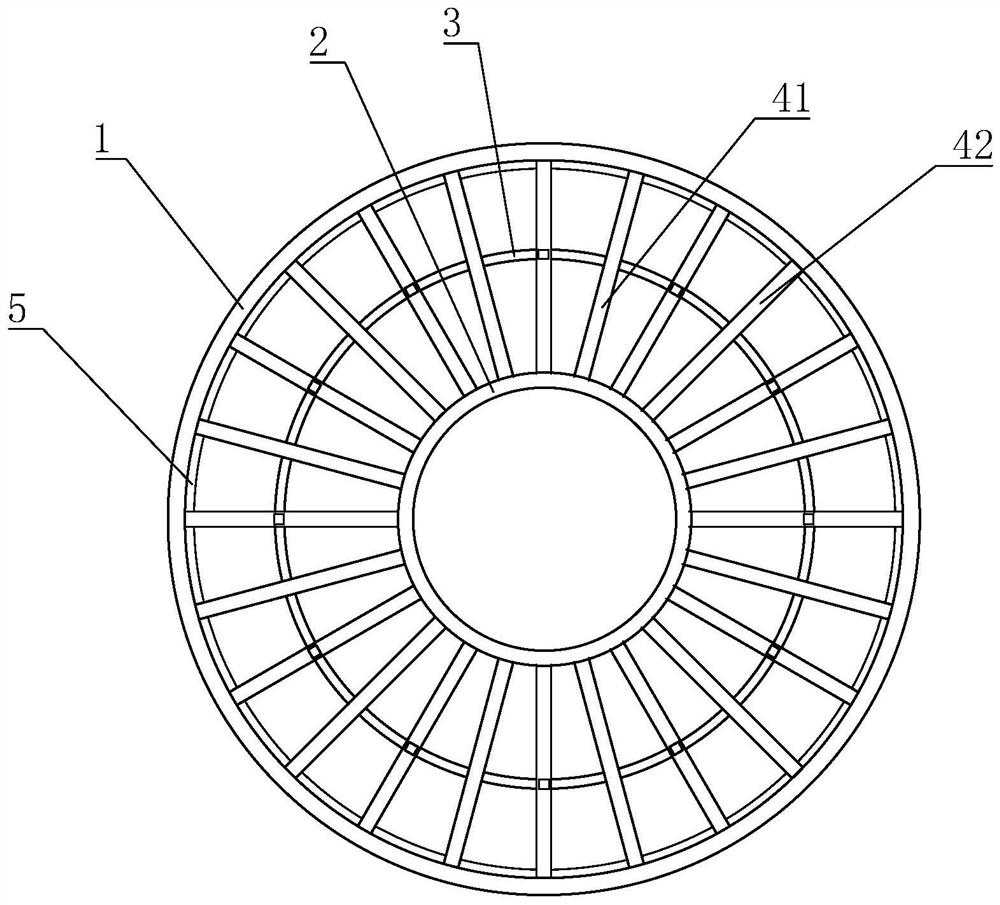

[0021] A method for dismantling a conical structure at the top of a prilling tower. The conical structure includes a central ring beam 2, an edge ring beam 3, and an obliquely fixed connection to the central ring beam 2, Between the edge ring beam 3 and the inner wall of the prilling tower 1, there are multiple connecting inclined beams evenly distributed along the circumferential direction, generally 24, and the part of the connecting inclined beams located between the central ring beam 2 and the edge ring beam 3 is defined as The inner beam 41 defines the part of the connecting inclined beam located between the edge ring beam 3 and the inner wall of the prilling tower 1 as the outer beam 42, and a circle is formed between the outer beam 42 and the inner wall of the prilling tower 1 for operators to stand and The annular workbench 5 that move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com