Method and equipment for preventing rock burst through pressure relief of coal seam ultra-long large-diameter drill hole

A drilling pressure relief and rock burst technology, which is applied in mining equipment, ground mining, earthwork drilling and mining, etc., can solve the problem of not being able to ensure that the large-diameter drilling trajectory of the coal seam does not deviate from the design, and weaken the coal body around the roadway to resist dynamic load impact The ability of large-diameter coal seam drilling to reduce the anti-scour effect, etc., to avoid long-term occupation of the pedestrian roadway section, enhance the ability to resist dynamic load impact, and avoid the effect of moving back and forth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below, examples of embodiments are shown in the drawings, wherein the same or similar labels from beginning to end indicate the same or similar elements or elements with the same or similar functions. The embodiments described below by reference to the accompanying drawings are exemplary and are intended to be used to explain the present invention, and cannot be construed as a limitation of the present invention.

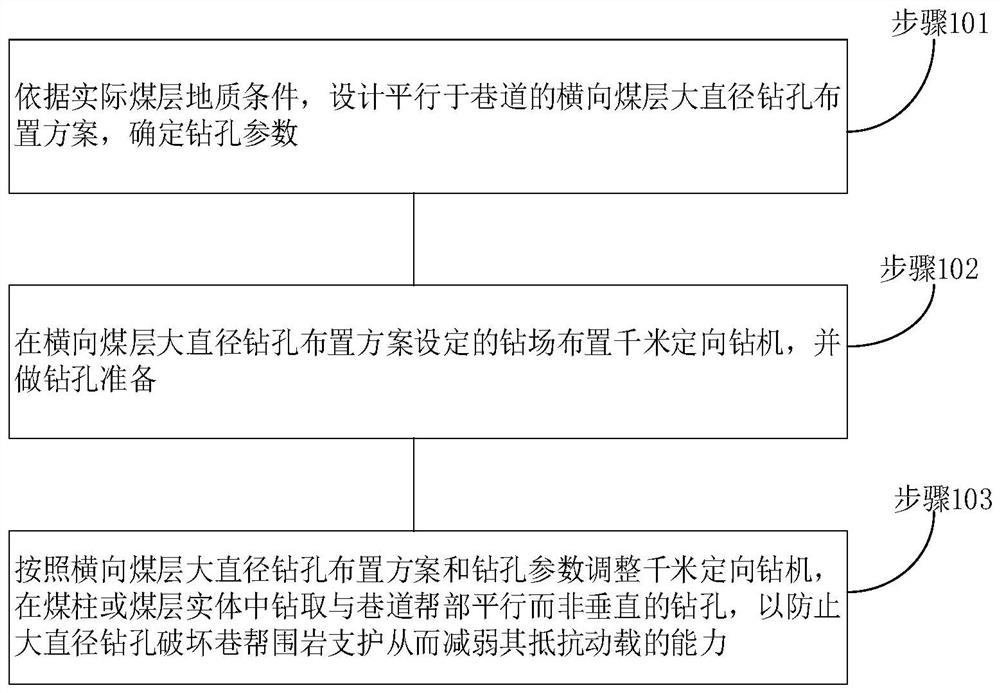

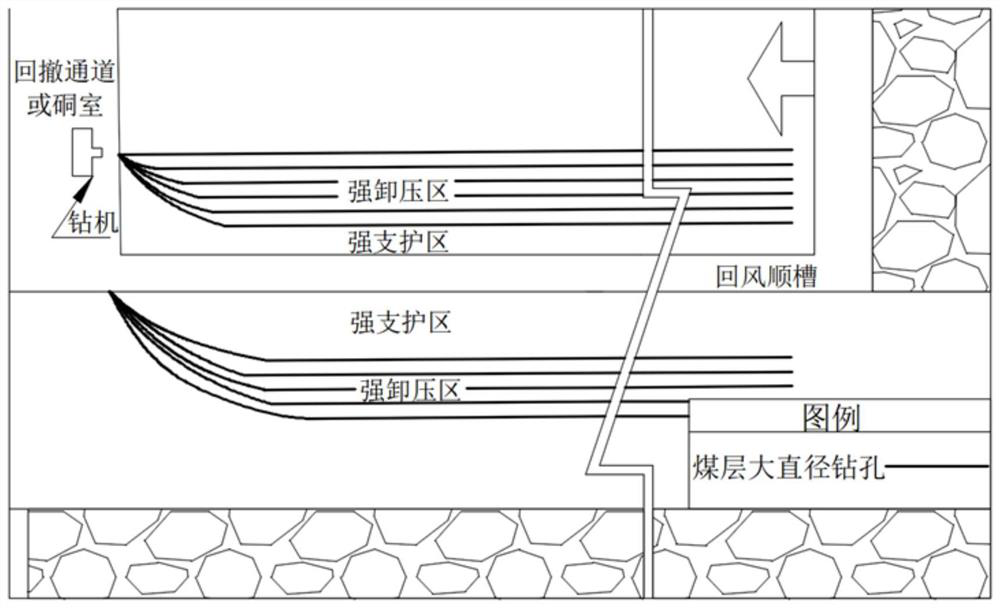

[0036] Figure 2 Schematic diagram of a coal seam ultra-long diameter drilling pressure relief method provided for an embodiment of the present invention. include:

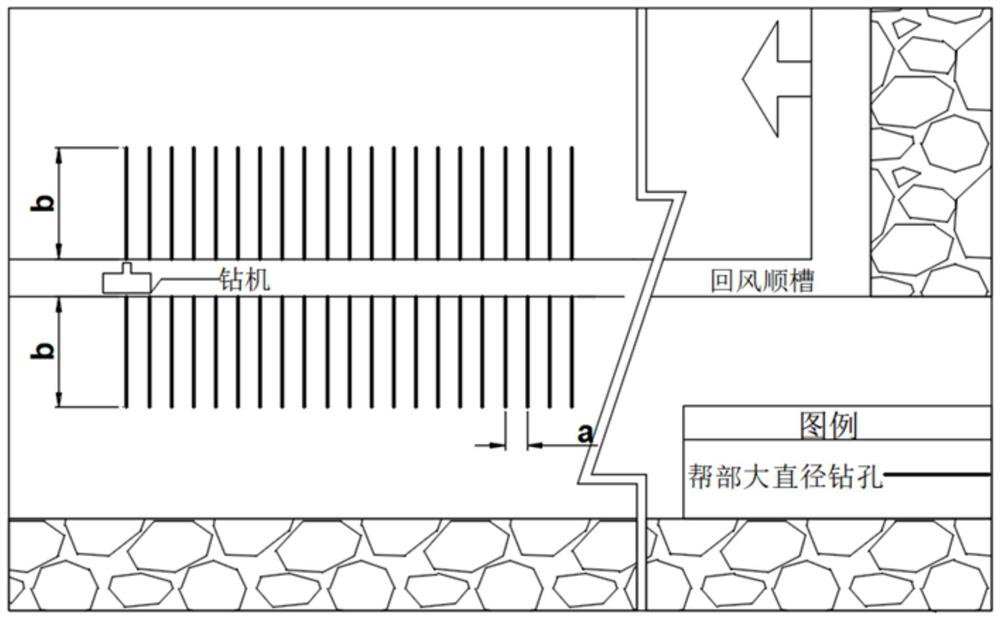

[0037] Step 101: According to the actual coal seam geological conditions, design a large-diameter drilling arrangement scheme for transverse coal seam parallel to the roadway, and determine the drilling parameters.

[0038] The present invention is aimed at the case of large diameter drilling of coal seams to relieve pressure, first of all,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com