Piston sealing structure of hydraulic drive piston hydrogen compressor

A technology of sealing structure and compressor, which is applied in the direction of piston rings, liquid variable capacity machines, mechanical equipment, etc., can solve the problems of universal plug failure, achieve reliable structure, long service life, and prevent uneven changes in outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

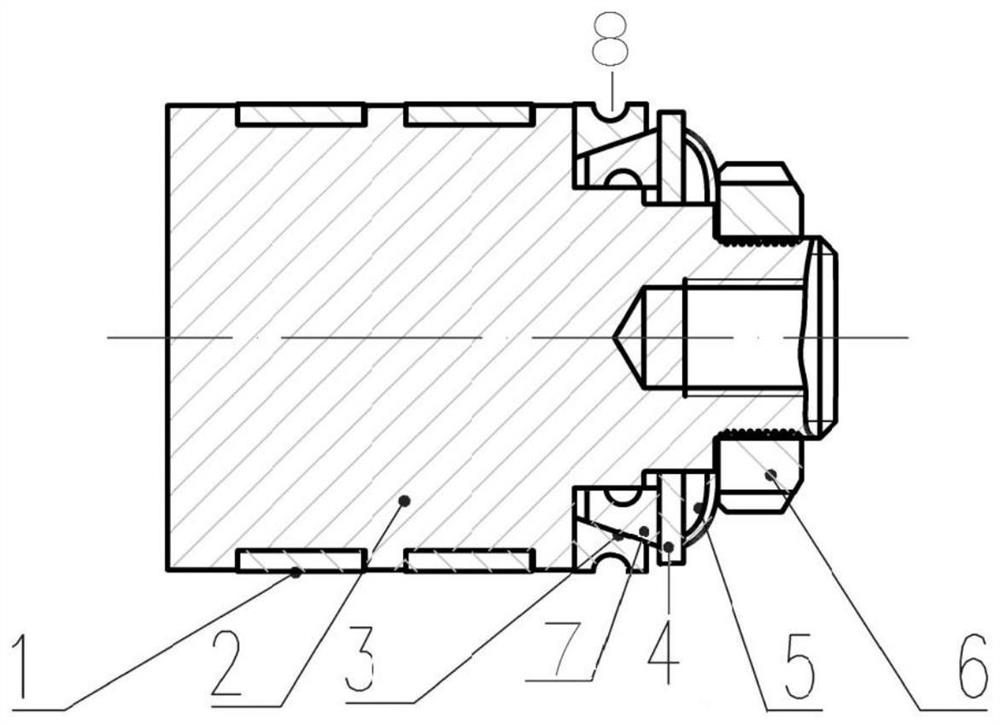

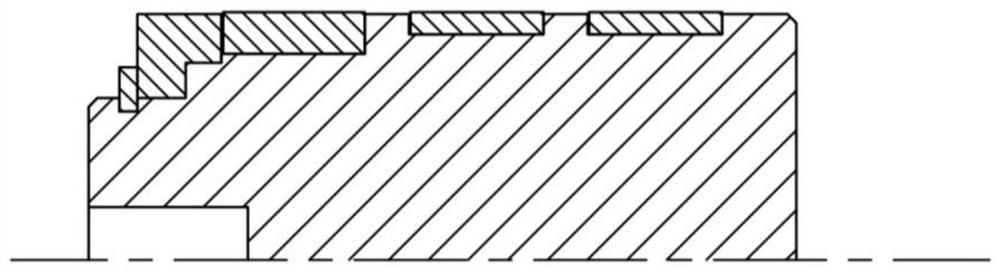

[0020] Embodiment 1: A piston seal structure of a liquid-driven piston hydrogen compressor, including two support rings 1 sleeved on the piston body 2, and sleeved on the end of the piston body 2 away from the piston rod.

[0021] The elastic sealing assembly includes a first ring 3 and a second ring 7, the first ring 3 is sleeved on the outer wall of the second ring 7, and the contact surface between the first ring 3 and the second ring 7 is a conical surface There is a gap between the end surface of the second ring member 7 away from the extrusion assembly and the end surface of the piston body 2 . When the elastic sealing assembly is squeezed, it will generate force to the piston body 2 and the cylinder respectively, so that the second ring 7 is in close contact with the piston body 2, while the first ring 3 is in close contact with the cylinder wall.

[0022] Grooves 8 are formed at the center of the first ring 3 close to the side wall of the cylinder, and at the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com