System and method for measuring emission angle of optical antenna

An optical antenna and measurement system technology, applied in radio wave measurement systems, measurement devices, measurement angles and other directions, can solve problems such as the influence of the optical system, the poor accuracy of releasing the ball, and the difficulty of calibration, achieve simple and accurate calculation, improve measurement accuracy, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

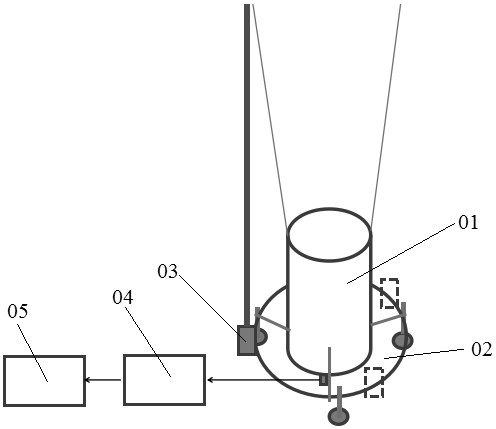

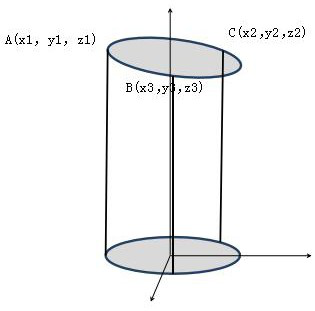

[0042] A measurement system for the emission angle of an optical antenna, such as figure 1 As shown, it includes a laser emitting device 03, a photoelectric conversion device 04, a data acquisition and processing device 05, a horizontal inclinometer 45 and an equipment support 02; the receiving end of the optical antenna 01 is connected with the photoelectric conversion device 04 and the data acquisition and processing device 05 in sequence; The outer side of the optical antenna 01 is equipped with an equipment bracket 02, and the optical antenna 01 and the equipment bracket 02 are arranged on a concentric axis; a horizontal inclinometer 45 and several laser emitting devices 03 are arranged on the circumference of the equipment bracket 02; the photoelectric conversion The device 04 is used to collect the echo signal of the optical antenna 01 and convert it into an electrical signal, and the data collection and processing device 05 is used to collect the electrical signal and co...

Embodiment 2

[0047] This embodiment is optimized on the basis of embodiment 1, such as Figure 6 As shown, the equipment support 02 includes an annular main support 41, a coaxial support 43, a horizontal support frame 42 and a laser emitting hanger 44, and several coaxial supports 43, laser emitting Hanger 44, horizontal support frame 42; the ring-shaped main bracket 41 is sleeved on the outside of the optical antenna 01, and the ring-shaped main bracket 41 and the optical antenna 01 are concentrically arranged, and the coaxial bracket 43 passes through the ring-shaped main bracket 41 transversely And contact with the optical antenna 01 ; the laser emitting device 03 is arranged on the laser emitting hanger 44 , and the horizontal inclinometer 45 is arranged on the annular main support 41 .

[0048] Further, several coaxial brackets 43 , laser emitting hangers 44 , and horizontal support brackets 42 are equidistantly arranged in the circumferential direction of the annular main bracket 41 ...

Embodiment 3

[0052] This embodiment is optimized on the basis of embodiment 2, such as Figure 7 As shown, the coaxial bracket 43 includes a T-shaped bracket 431, a bracket main body 432, a bracket fine-tuning device 433 and a locking buckle 434. The fine-tuning device 433 is connected with the ring-shaped main bracket 41, and the bracket main body 432 is provided with several grooves along the length direction, and the locking buckle 434 passes through the bracket fine-tuning device 433 and locks with the grooves; the bracket main body 432 A T-shaped bracket 431 is provided at the abutting end of the bracket body 432 , and scale lines are provided along the length direction of the bracket main body 432 .

[0053] Further, the outer end of the bracket main body 432 is provided with a bracket auxiliary scale 435 feet.

[0054] Further, the bracket fine-tuning device 433 is rotationally connected with the ring-shaped main bracket 41 , and the bracket main body 432 is slidably connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com