Ontology-based CMM probe diameter intelligent reasoning method

A reasoning method and probe technology, applied in the direction of reasoning methods, geometric CAD, special data processing applications, etc., to achieve the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is a specific example of the present invention, which shows the automatic generation of the probe diameter intelligent reasoning type. However, the present invention is not limited to these examples.

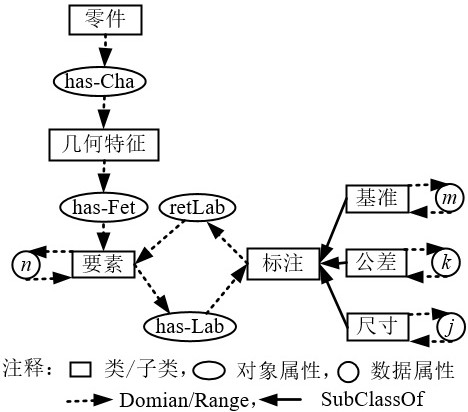

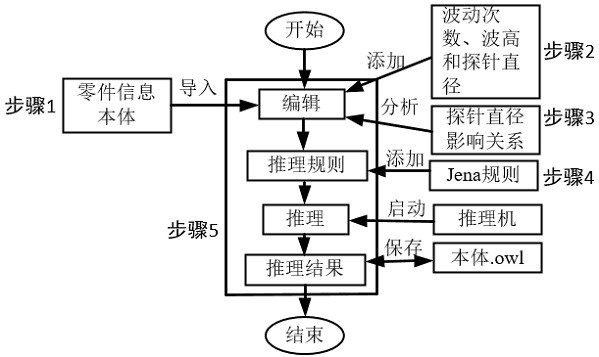

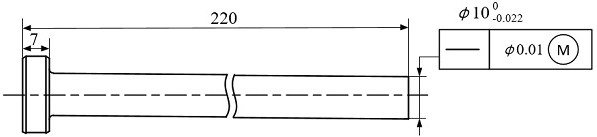

[0042] Step 1: Establish a 3D model of the part in the software UG10.0 based on MBD technology, and the individual marks are as follows image 3 As shown, the ontology model of part geometric information and non-geometric information is constructed, such as Figure 4 shown.

[0043] After step 1, proceed to step 2.

[0044] Step 2: Knowing the number of fluctuations per revolution, wave height and probe diameter, construct the data attribute of the number of fluctuations per revolution, that is, FLU=15, 50, 150, 500; construct the data attribute of wave height, that is, WT=2.5 , 5, 10, 20, 40, 80; construct the data attribute of the probe diameter, that is, PRO=0.025, 0.1, 1, 2, 3, 5, 8, 20, 50.

[0045] After step 2, proceed to step 3.

[0046] Step 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com