Equipment fault diagnosis method

A diagnostic method and equipment failure technology, applied in the field of equipment operation guarantee, can solve problems such as judgment lag, fault diagnosis deviation, omission, etc., and achieve the effect of improving accuracy and effectiveness, reducing equipment failure rate, and exerting economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

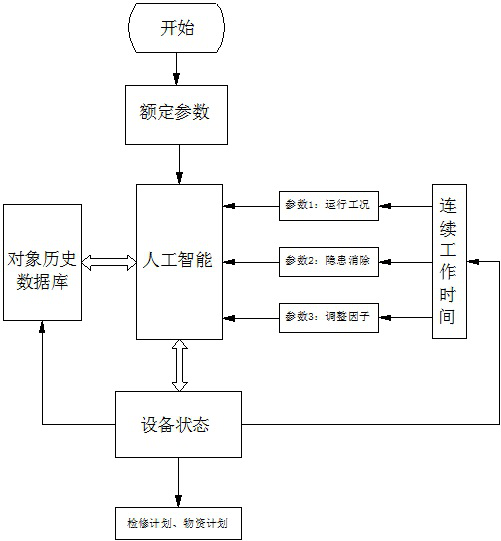

[0042] A device fault diagnosis method, it comprises the following steps:

[0043] Step 1: Determine the category, rated parameters, and initial life cycle of the research equipment;

[0044] Step 2: Establish an expert system model rule base according to the characteristics of object categories;

[0045] Step 3: Establish object history database;

[0046] Step 4: Introduce artificial neural network to model high-dimensional nonlinear problems;

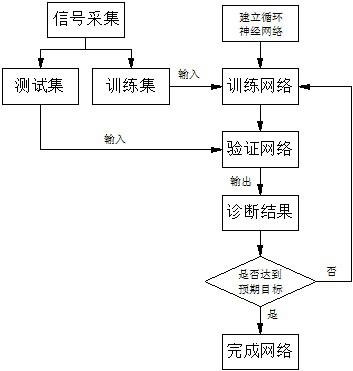

[0047] Step 5: use BP neural network to realize fault diagnosis;

[0048] The category of equipment mentioned in step 1 includes machinery, motors, valves, or other equipment, and the rated parameters of the equipment include power, voltage, frequency, speed, temperature, and other rated parameters that affect the use of the equipment;

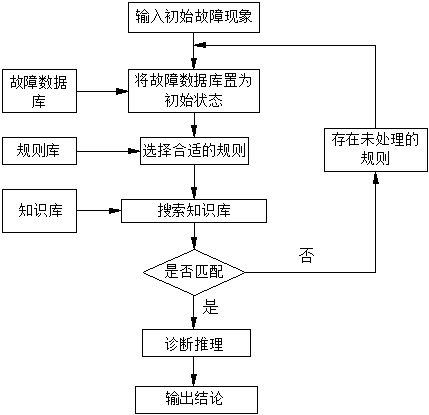

[0049] The expert system model rule base described in step 2 includes a fault database, a rule base, and a knowledge base; as a useful supplement to the artificial neural network, the RBF neural ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com