Novel water curtain environment-friendly paint spraying table

A water curtain and environmental protection technology, applied in spray booths, spray devices, etc., can solve the problems of spray paint quality stability and spray efficiency, affect the health of workers, and low degree of automation, and achieve convenient maintenance, low cost, and overall low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

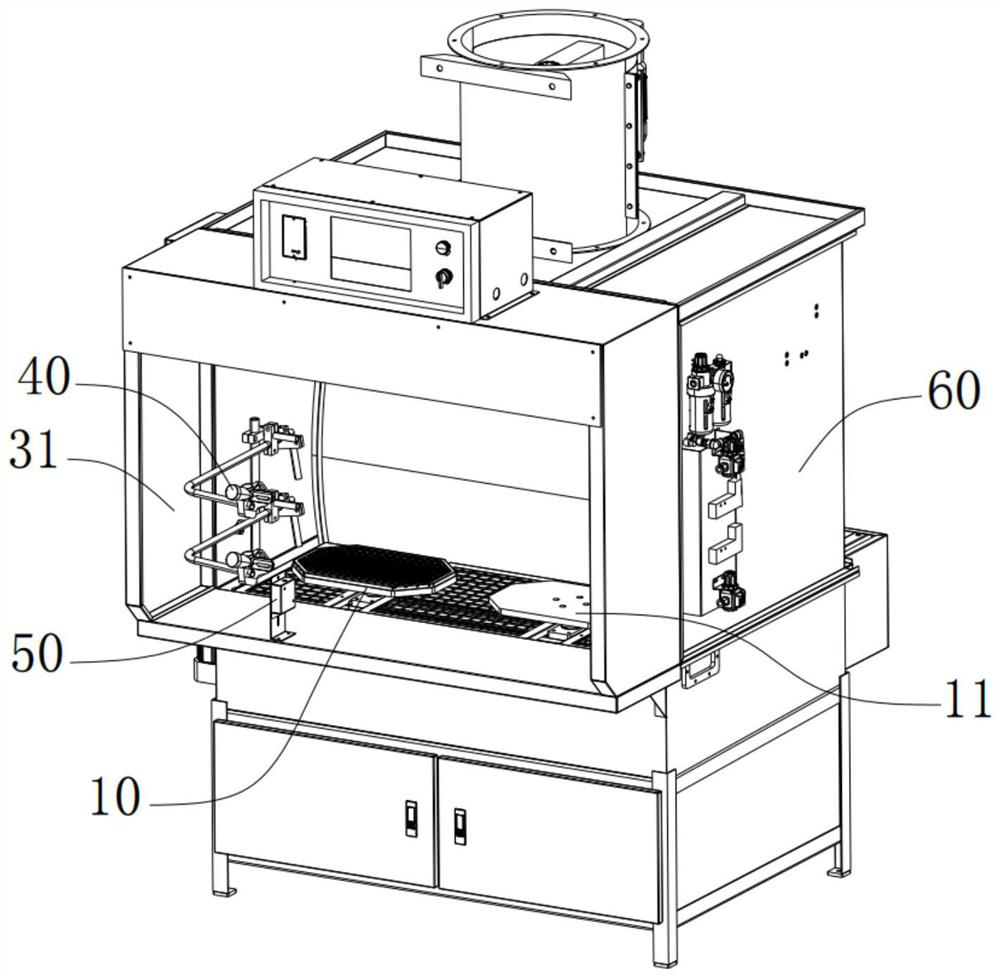

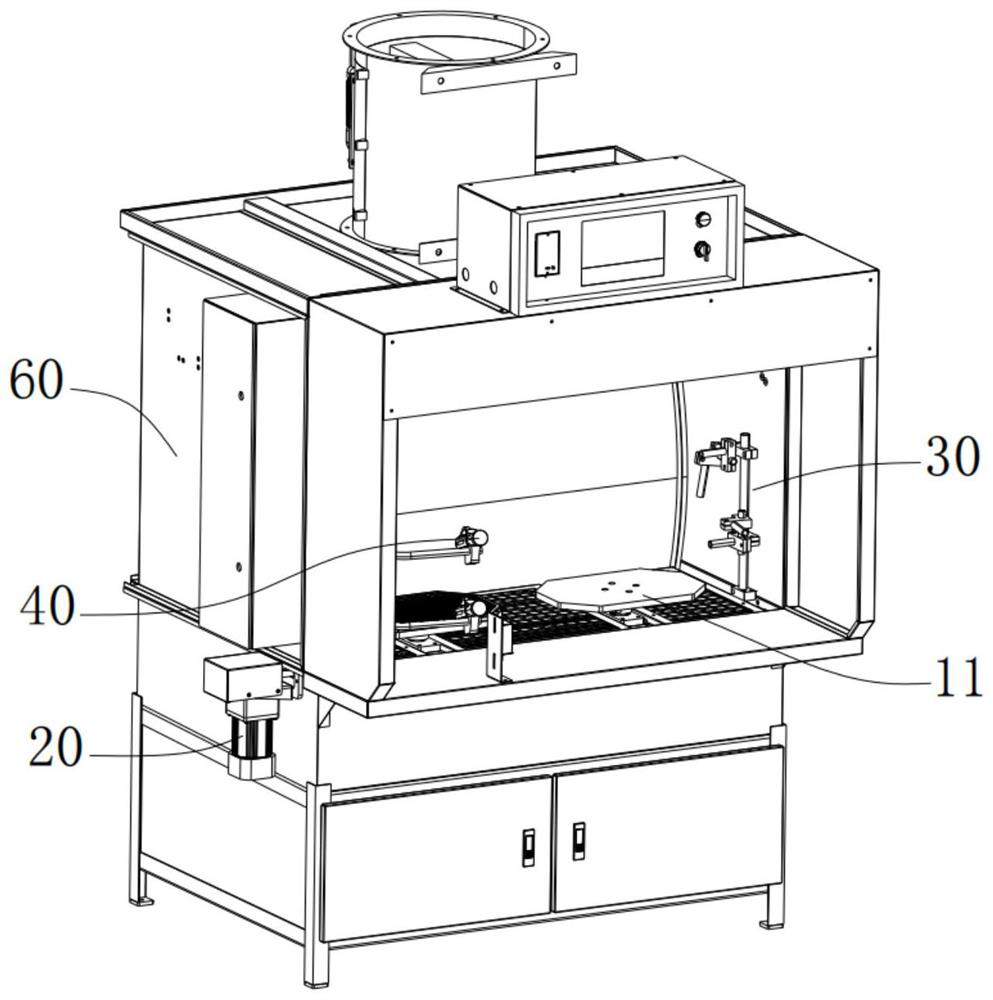

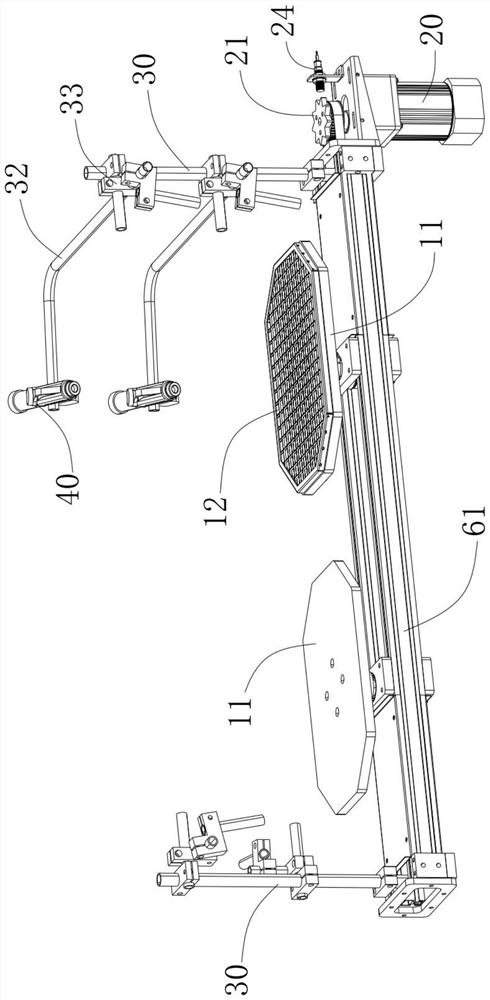

[0034] as attached figure 1 - 2, 4 - 8, and 11 show a new type of water curtain environmental protection painting booth provided by the present invention, including:

[0035] The painting turntable 10 is used to support the product and drive the product to rotate on at least one horizontal plane. According to the product painting processing requirements, when the product needs to be driven to rotate only on a single horizontal plane, the painting turntable 10 only needs to use a single set of driving sources. And when rotating at low speed, there is no need to set up a fixing mechanism to fix the product. When it is necessary to drive the product to rotate on multiple horizontal planes, it is necessary to set up multiple sets of driving sources accordingly, and correspondingly need to set up a corresponding fixing mechanism for fixing according to the product structure;

[0036] The spray gun installation stand 30 is used to set up the paint spray gun 40, and the spray gun ins...

Embodiment 2

[0049] as attached figure 1 As shown in -11, the difference between this embodiment and the above embodiments is that the angle adjustment connecting arm 31 includes multiple sets of connecting pipes 32 and multiple sets of steering clamp blocks 33, and at least two sets of steering clamp blocks 33 are provided for clamping Tighten the clamping groove 34 of the connecting pipe 32, at least two groups of clamping grooves 34 are not parallel to each other in the axial direction, the connecting pipe 32 is connected to each other through the steering clamp block 33, after the connection angle is adjusted, the clamping groove 34 can be tightened by the fastener. lock;

[0050] Among them, when the flexible bracket is used as the angle adjustment arm 31, when the painting speed is too fast or the opening and closing frequency is high, it will cause the paint spray gun 40 to vibrate, which will affect the painting accuracy. When the requirements are not high, compared with the use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com