Gantry crane track foundation

A gantry crane and track technology, applied in the field of construction auxiliary tools, can solve the problems of the gantry crane track foundation cannot be reused many times, the use cost of the gantry crane track foundation is high, and the construction period is long, so as to save construction time, facilitate transportation, and cause noise. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-4 The application is described in further detail.

[0041] The embodiment of the application discloses a gantry crane track foundation.

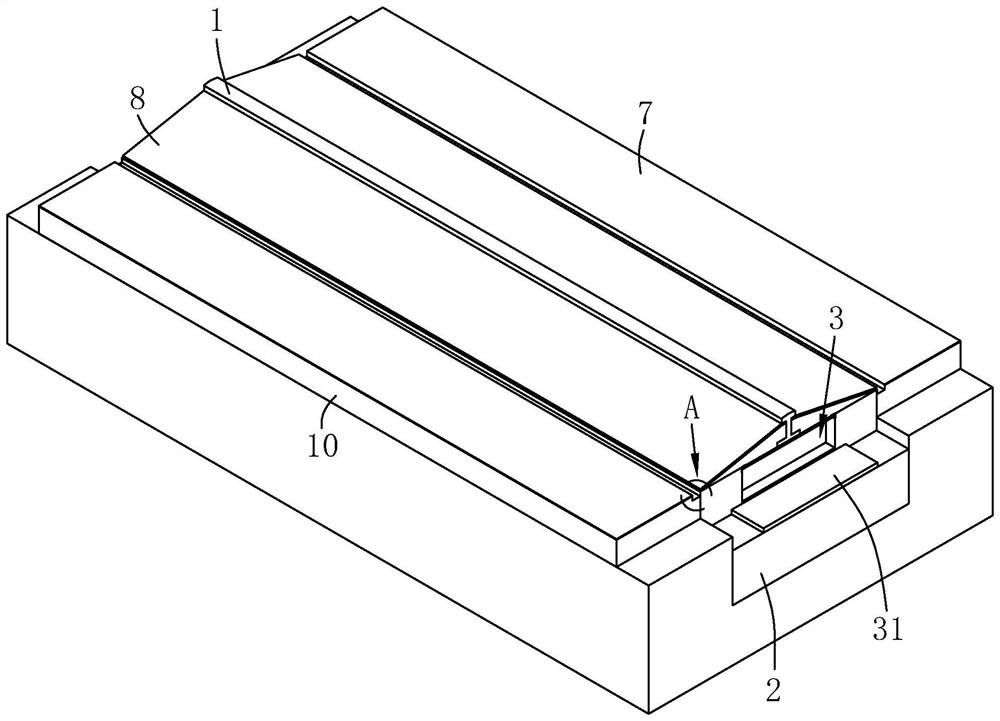

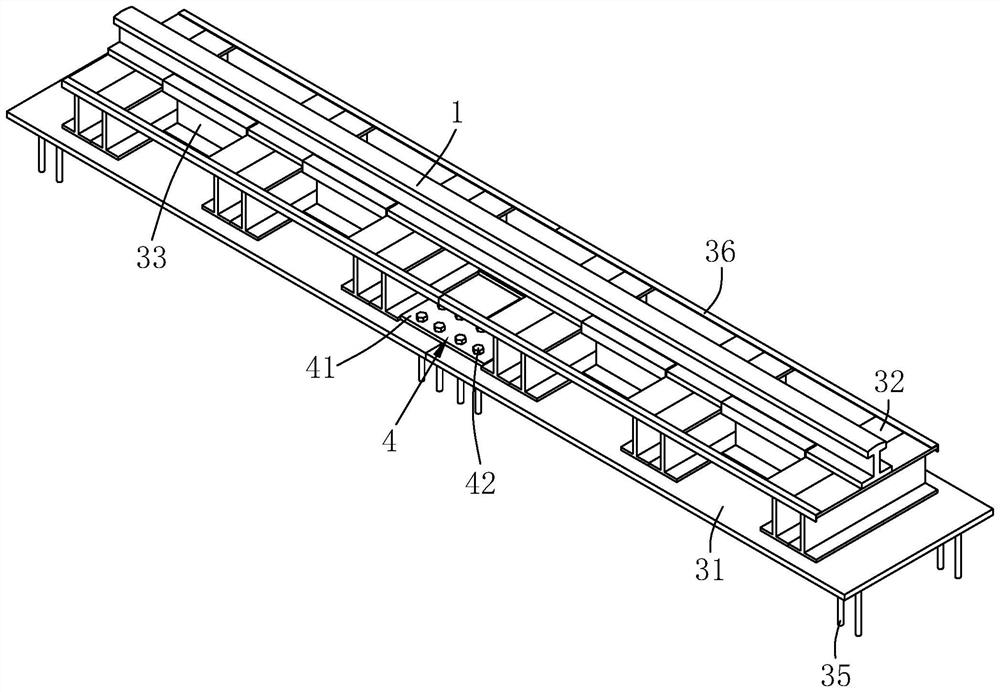

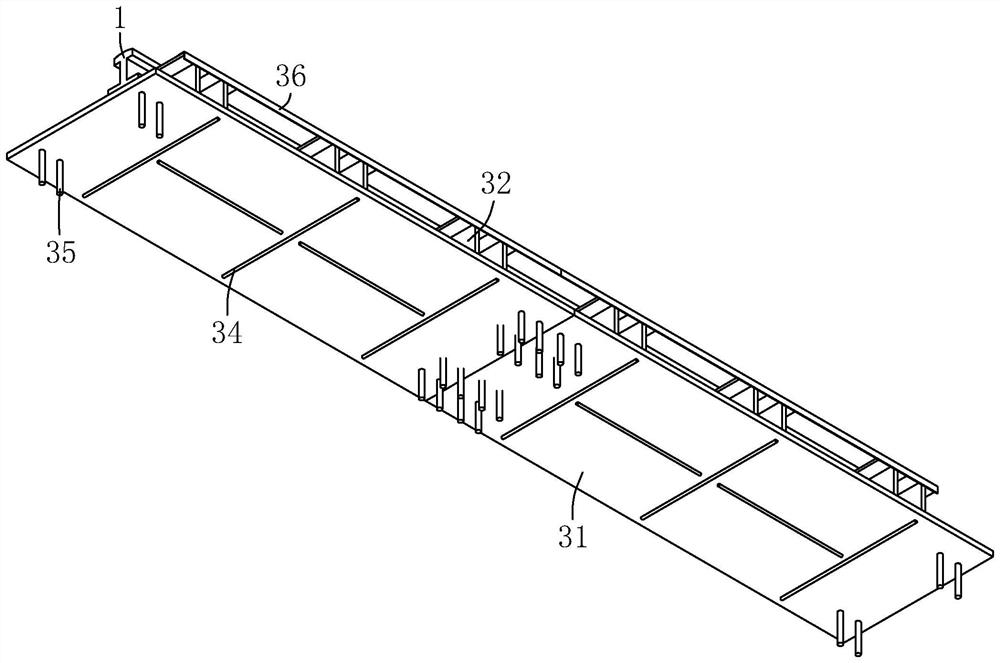

[0042] refer to figure 1 and figure 2 A gantry crane track foundation includes a steel track 1, a lime soil layer 2, a multi-section installation base 3 for fixing the steel track 1, and a connecting assembly 4 for connecting two adjacent installation bases 3; the installation base 3 includes a pressure pad 31. A plurality of fixed blocks 32 and I-beams 33 arranged between two adjacent fixed blocks 32, grooves are opened on the ground, and the lime soil layer 2 is laid in the grooves. The lime soil layer 2 used in this embodiment The volume ratio of lime and soil is 3:7.

[0043] refer to figure 1 and figure 2, the pressure backing plate 31 is placed on the lime-soil layer 2, and the length direction of the pressure backing plate 31 is arranged parallel to the length direction of the lime-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com