A high wear-resistant rubber hose

A rubber hose, high wear-resistant technology, applied in the direction of hose, pipe, pipeline protection, etc., can solve the problems of shortened use time of rubber hose, low strength and wear resistance, and wear of the outer layer of the hose, etc. Achieve the effect of improving softness and compression resistance, enhancing wear resistance and reducing wear surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

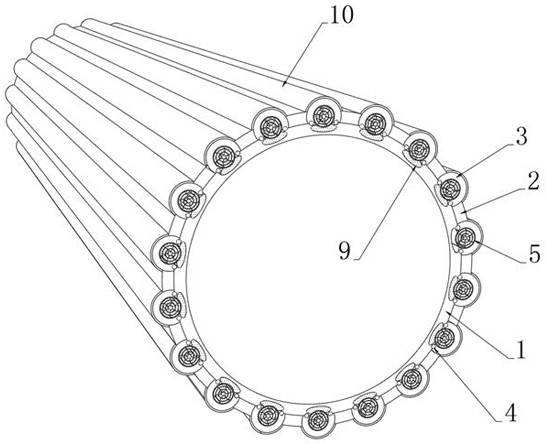

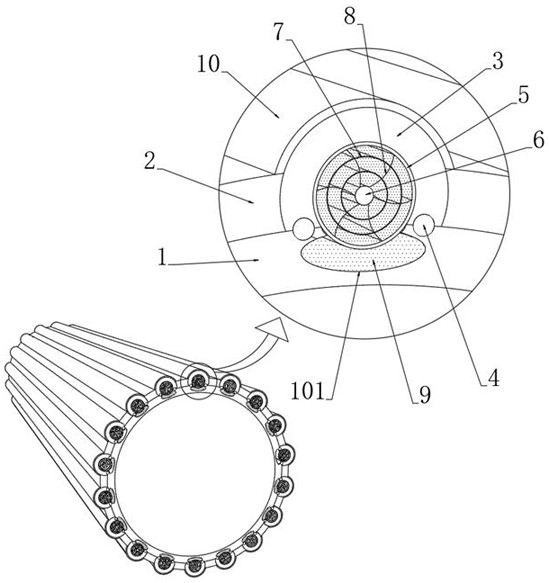

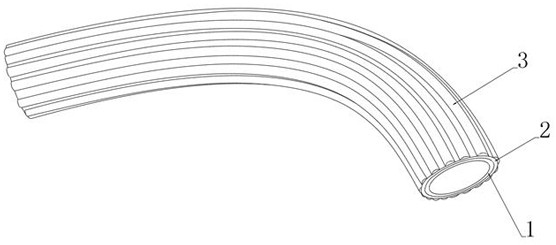

[0041] see Figure 1-4 , a highly wear-resistant rubber hose, including an inner rubber layer 1 and an outer rubber layer 2 that are connected with the inner and outer layers. The outer end wall of the outer rubber layer 2 is annularly distributed with a plurality of convex wear-resistant protruding outwards. Adhesive layer 3, the lower end walls of a plurality of convex anti-abrasion adhesive layers 3 are embedded and connected with the outer end walls of the inner adhesive layer 1. The inner adhesive layer 1, the outer adhesive layer 2 and the convex abrasion-resistant adhesive layer 3 are all composed of The raw material components in parts are composed of 50-65 parts of natural rubber, 45-65 parts of nitrile rubber, 35-50 parts of cis-butadiene rubber, 60-80 parts of butadiene nitrile, and 5-10 parts of anti-aging agent.

[0042] see Figure 4-6 , the plurality of convex anti-abrasion rubber layers 3 and the outer rubber layer 2 are integrally formed, and one-shot injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com