Air compressor equipment for electric power system

An air compressor and power system technology, applied in mechanical equipment, supporting machines, machines/engines, etc., can solve problems such as affecting work progress, lack of protective devices, collisions, etc., to achieve the effect of convenient operation and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

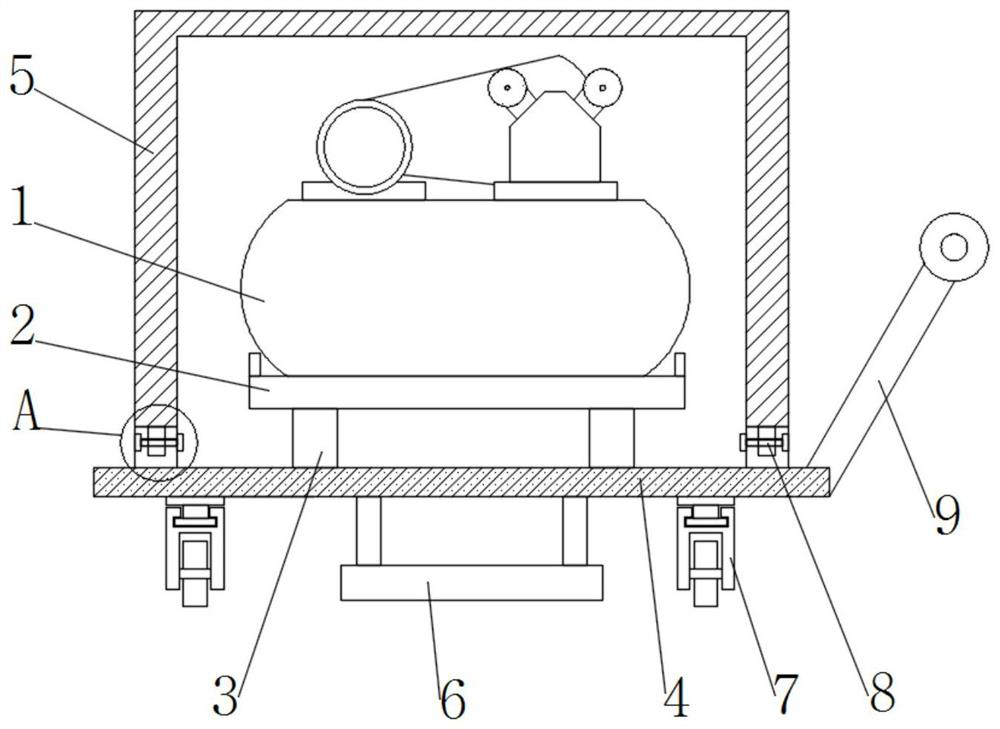

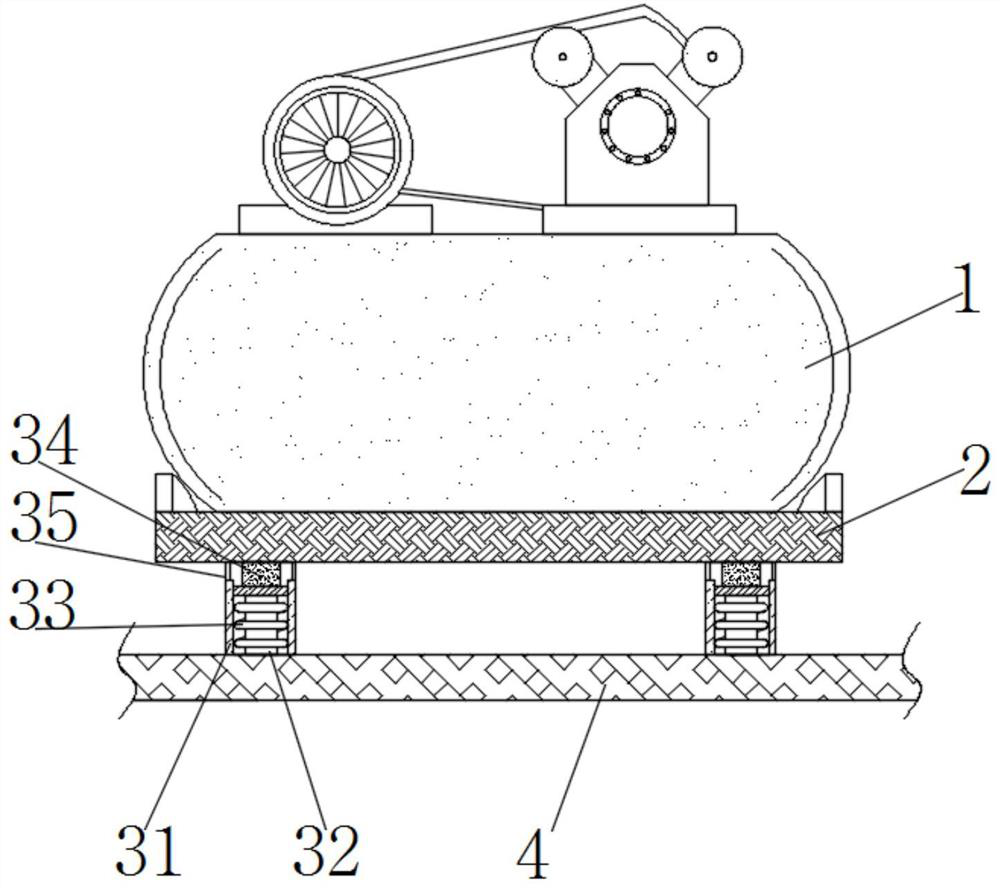

[0028] Such as Figure 1-5 As shown, the present invention provides an air compressor device used in a power system, including an air compressor body 1, a fixed plate 2 is fixedly installed on the bottom of the air compressor body 1, and a shock absorbing assembly is arranged on the bottom of the fixed plate 2 3. The bottom of the shock absorbing assembly 3 is provided with a stable base 4, the bottom of the stable base 4 is provided with a fixed assembly 6, the upper part of the stable base 4 is provided with a connecting assembly 8, the upper part of the connecting assembly 8 is provided with a protective cover 5, and the shock absorbing assembly 3 includes the installation sleeve 31, the interior of the installation sleeve 31 is fixedly installed with a shock-absorbing elastic column 32, the outside of the shock-absorbing elastic column 32 is provided with a buffer spring 33, the upper part of the buffer spring 33 is fixedly installed with a connecting block 34, and the uppe...

Embodiment 2

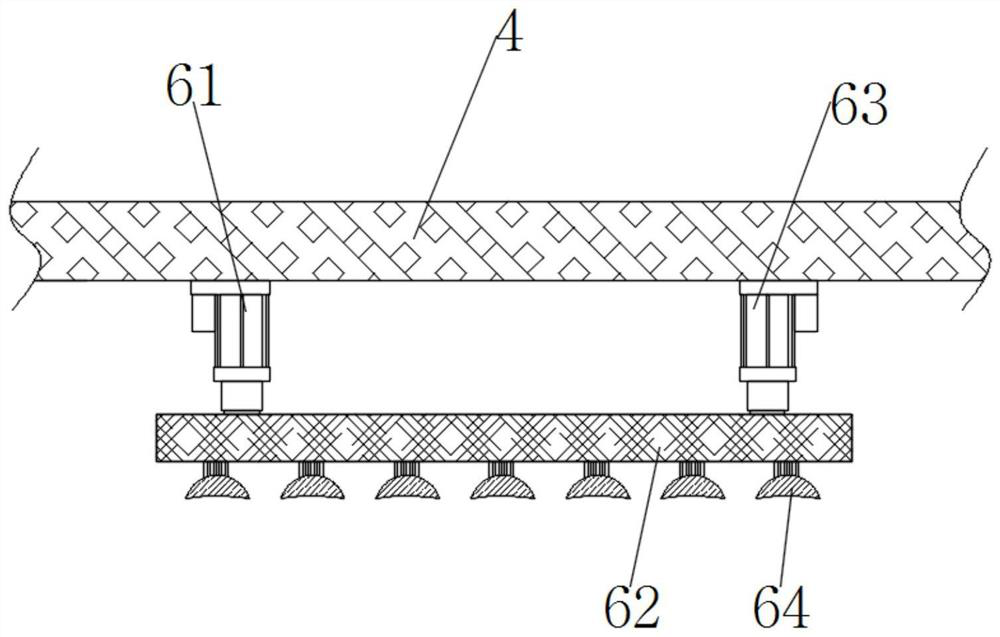

[0030] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the fixing assembly 6 includes a first miniature electric telescopic rod 61, and the first miniature electric telescopic rod 61 is fixedly installed on the lower part of the stable base 4, The bottom of the first miniature electric telescopic rod 61 is provided with a stable pressing plate 62, the bottom of the stable pressing plate 62 is fixedly equipped with a suction cup 64, and the top of the stable pressing plate 62 is fixedly installed with a second miniature electric telescopic rod 63, away from the second miniature electric telescopic rod 63 The left side of the left side is provided with a first miniature electric telescopic rod 61, and the upper part of the second miniature electric telescopic rod 63 is fixedly connected with a stable base 4. When the air compressor body 1 is placed by setting the fixing assembly 6, the first miniature el...

Embodiment 3

[0032] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the connecting assembly 8 includes a connecting seat 81, the connecting seat 81 is fixedly installed on the upper part of the stable base 4, and the lower part of the protective cover 5 is fixedly installed with The connecting block 82, the inside of the connecting seat 81 and the inside of the connecting block 82 are provided with a transverse rectangular groove 83, the outer wall of the connecting block 82 is flexibly connected with the inside of the connecting seat 81, and the left side of the connecting seat 81 is provided with a threaded groove 84, the internal screw thread of threaded groove 84 is connected with threaded cap 86, and the internal activity of transverse rectangular groove 83 is equipped with circular connecting rod 85, and the left side of circular connecting rod 85 is fixedly installed with threaded cap 86, and the circular con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com