Auxiliary device for measuring electrical variable

A technology of auxiliary equipment and electric variables, which is applied in the direction of measuring electric variables, parts of electric measuring instruments, measuring electricity, etc., can solve problems that affect the measurement efficiency of equipment, and cannot add resistance sheets to the base, so as to increase flexibility and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

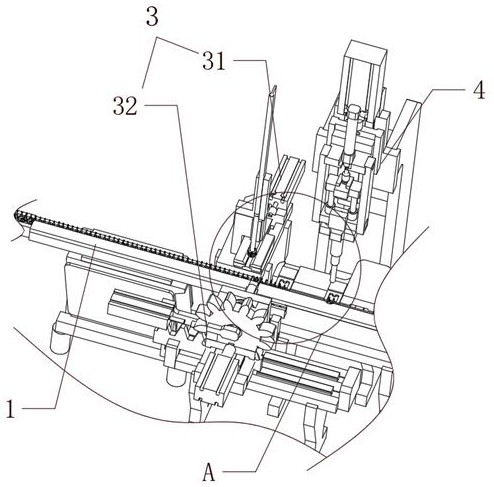

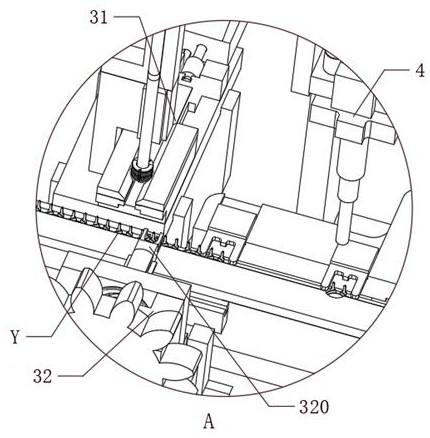

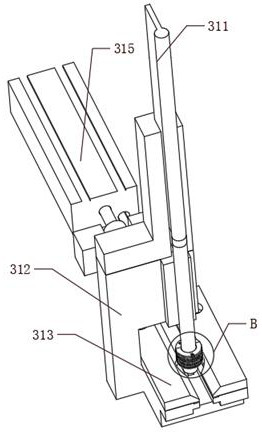

[0031] Such as Figure 1-Figure 10 As shown, an auxiliary device for measuring electrical variables includes an adding mechanism 3 and a pressing mechanism 4 for matching the resistance sheet G with the base Y. The adding mechanism 3 includes stacking components 31 respectively arranged on both sides of the conveying mechanism 1 1. Picking assembly 32, wherein the front end of picking assembly 32 has clamping head 320, and the front end of stacking assembly 31 has alignment notch 310 for inserting clamping head 320, and clamping head 320 will be placed in the resistive slice G in stacking assembly 31 transport To the upper part of the base Y, the pressing mechanism 4 pushes the resistance sheet G into the base Y. The stacking assembly 31 includes a stacking vertical bar 311, a stacking fixing bracket 312 for fixing the stacking vertical bar 311, and a stacking vertical bar 312 arranged on the stacking vertical bar. The stacking slide 313 at the bottom of 311, the stacking slid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap