Stir-frying and dust removing equipment for tea processing

A kind of dedusting equipment and tea technology, which is applied in tea treatment before extraction, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems affecting the quality of tea stir-frying and the effect of tea stir-frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

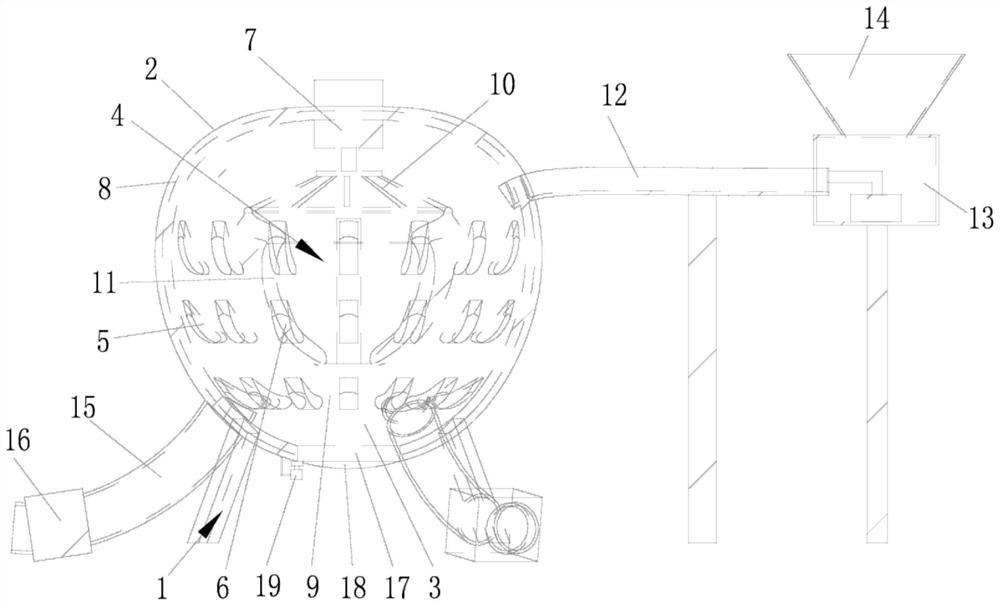

[0014] Such as figure 1 As shown, a kind of stir-frying and dust-removing equipment for tea processing includes a stir-frying stand 1, and the stir-frying stand 1 is provided with an outer casing 2 with an electric heating block 8 inside. The middle part of the stir-frying cavity 3 is provided with an arc-shaped stir-frying head 4, the inner wall of the stir-frying cavity 3 is provided with fixed stir-frying teeth 5 extending downward along the inner wall, and the outer wall of the arc-shaped stir-frying head 4 is provided with a The rotating and turning teeth 6 extending upward on the outer wall, the arc-shaped stirrer head 4 is connected to the output end of the forward and reverse stirrer motor 7, the upper outer side of the outer casing 2 is provided with a tea feeding assembly, and the tea feeding assembly The output end is arranged corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com