Device for realizing full-automatic scanning of test tubes

A fully automatic, test-tube technology, applied in the field of medical devices, can solve the problems of difficulty in ensuring scanning accuracy, high time and labor costs, and overwhelmed medical staff, so as to ensure timeliness and accuracy, reduce time, and ease work. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

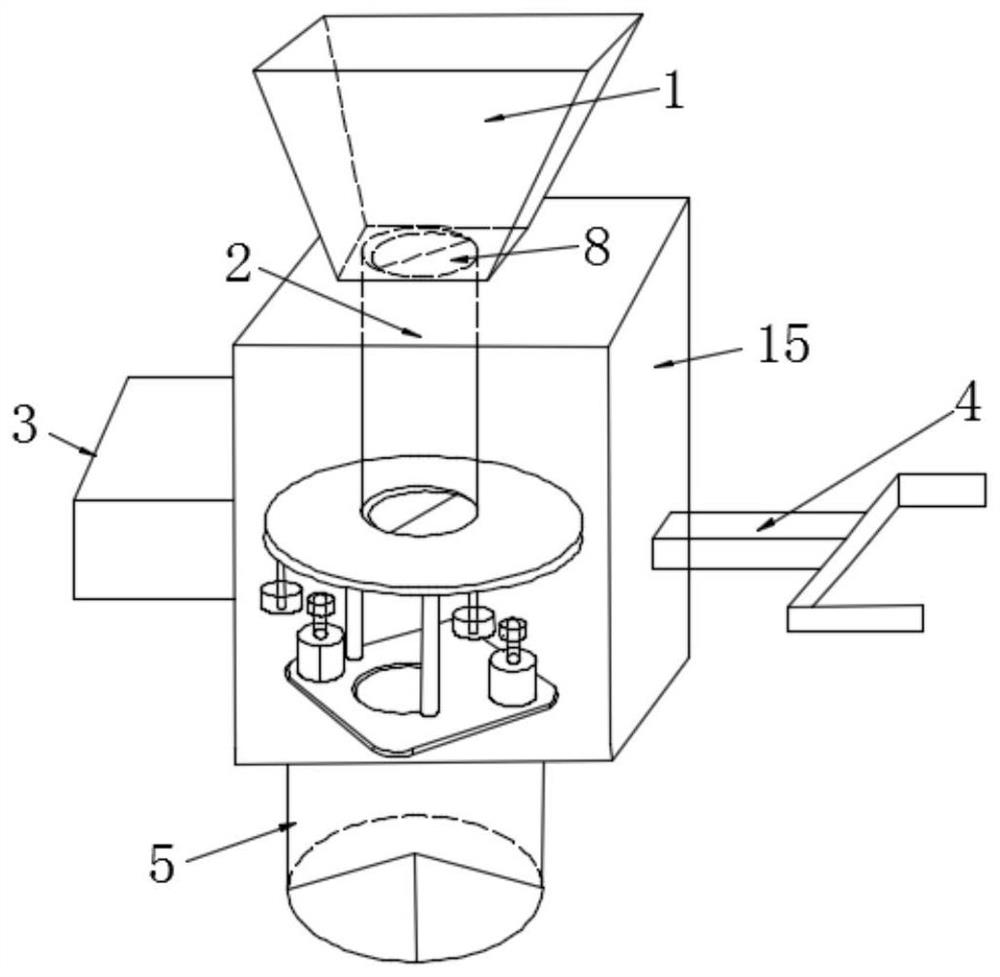

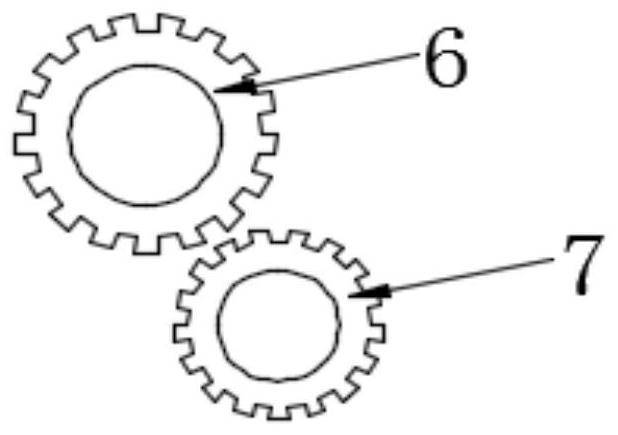

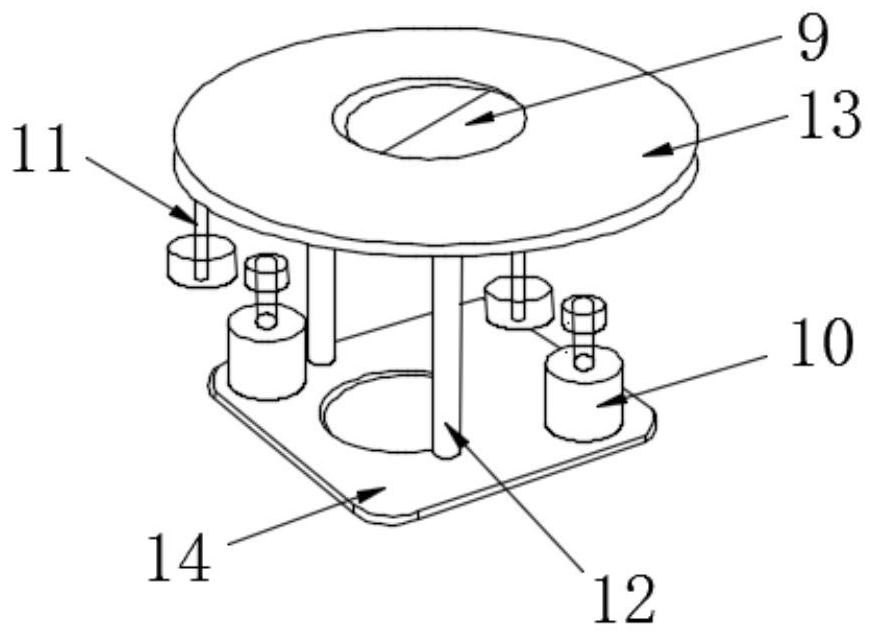

[0044] Such as figure 1 , figure 2 and Figure 5 As shown, the embodiment of the present application provides a device for fully automatic scanning of test tubes, including a receiving chamber 1, a scanning chamber 15 and a receiving chamber 5 for receiving dropped test tubes after scanning. The storage cylinder 2 of the test tube, the top of the storage cylinder 2 is connected with the bottom end of the accommodation chamber 1, and the side of the scanning chamber 15 perpendicular to the storage cylinder 2 is provided with a clamping mechanism 4 for clamping the scanner; A rotating device for driving the storage cylinder 2 to rotate is provided. The rotating device includes a rotating plate 13, a rotating assembly and a placement plate 14. The rotating assembly includes a motor 10, a driving wheel 7, a driven wheel 6 and a connecting rod 11. The driving wheel 7 is fixedly installed On the transmission shaft of the motor 10, the motor 10 is fixedly connected with the upper ...

Embodiment approach

[0049] As a specific implementation, the control device 3 includes a power supply, a processor and a controller, the power supply is electrically connected to the processor, the processor is electrically connected to the controller, and the controller is electrically connected to the motor 10 . The start and stop of the motor 10 are controlled by the processor and the controller, so as to realize automatic scanning. The power supply can be a battery, or an external 220V indoor power supply. The processor can be a single-chip microcomputer series chip. As far as the controller is concerned, it changes the wiring of the main circuit or the control circuit and changes the resistance value in the circuit to control the start of the motor. The master device of speed regulation, braking and reverse can be used to control the motor 10 to start and stop.

[0050] Such as image 3 As shown, as a specific embodiment, two first semicircular cover plates are provided at the bottom end of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap