Slab cast-rolling system and method for improving production efficiency of cast-rolling interface

A production efficiency and slab technology, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of low continuous rate, low production efficiency, large heat loss of slabs, etc., to improve direct loading rate and hot charging rate, improve efficiency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

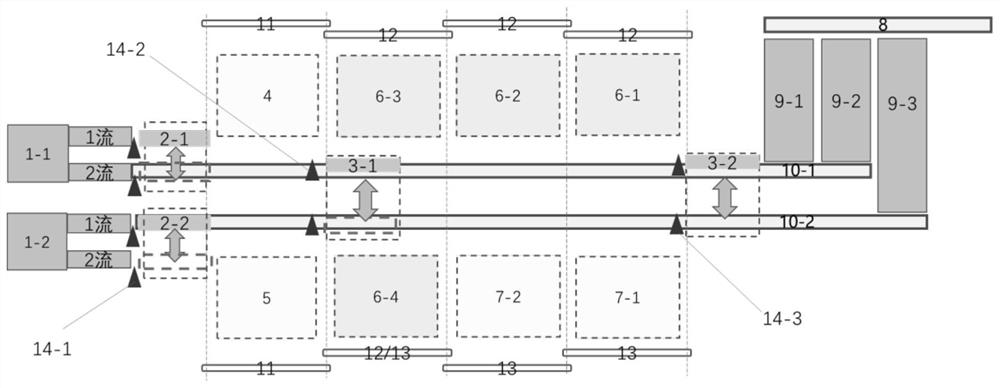

[0089] Such as figure 1 As shown, the present embodiment provides a slab casting and rolling system, and the slab casting and rolling system includes a first continuous casting machine 1-1, a second continuous casting machine 1-2, a first conveying roller table 10-1, and a second conveying roller table 10-1. Roller table 10-2, first heating furnace 9-1, second heating furnace 9-2 and third heating furnace 9-3; first conveying roller table 10-1 and first heating furnace 9-1 and second heating furnace The furnaces 9-2 are connected respectively; the second conveying roller table 10-2 is connected with the third heating furnace 9-3; the first continuous casting machine 1-1 only produces hot-charged slabs, and the second continuous casting machine 1-2 alternately produces Hot-charged slab and cold-charged slab; the first conveying roller table 10-1 can send the hot-charged slab into the first heating furnace 9-1 or the second heating furnace 9-2, and the second conveying roller ta...

Embodiment 2

[0097] This embodiment provides a method for improving the production efficiency of the casting-rolling interface by using the slab casting-rolling system of Embodiment 1. details as follows:

[0098] The first continuous casting machine 1-1 produces SPHC steel grade, and its chemical composition is shown in Table 1 below. The size is 200mm×1500mm×95000mm.

[0099] Table 1 The main chemical composition of SPHC (wt%)

[0100] C Si mn P S Alt margin 0.15 0.05 0.6 0.035 0.015 0.015 Fe and other unavoidable impurities

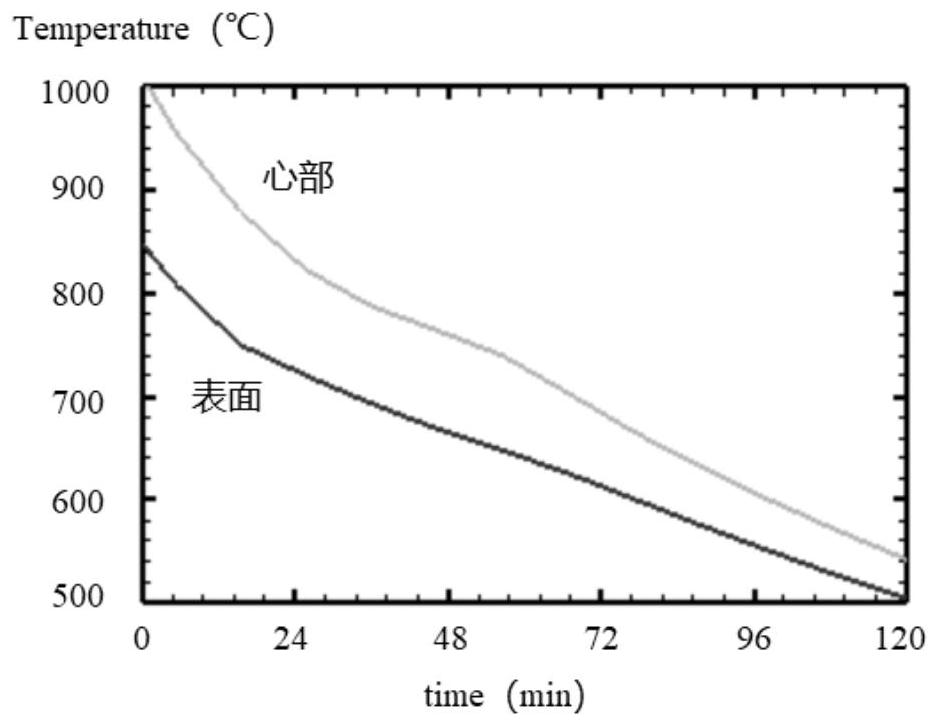

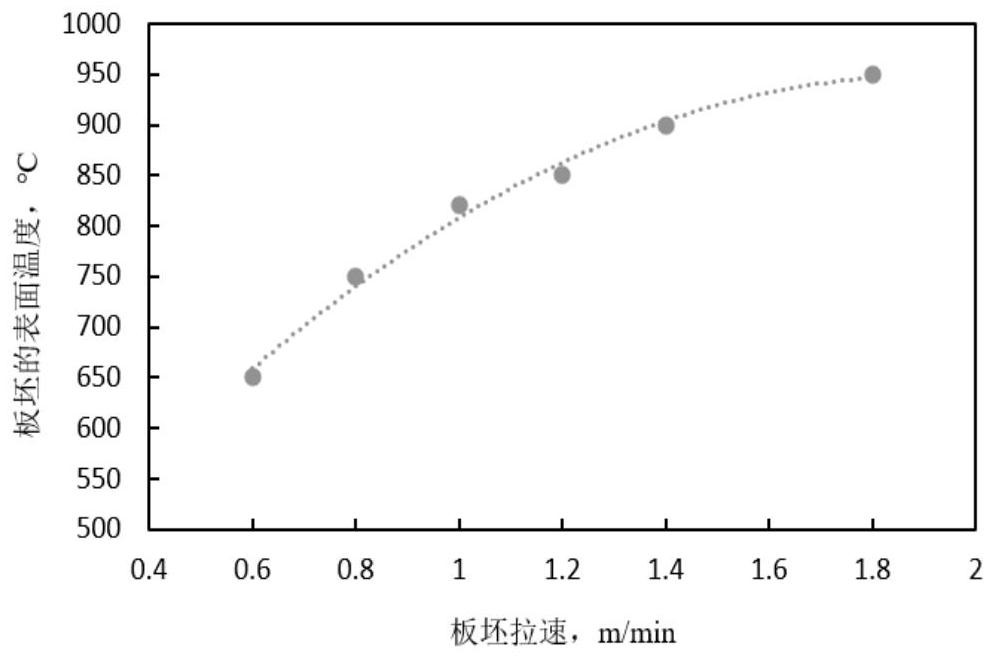

[0101] Scenario 1: When the first continuous casting machine 1-1 and the second continuous casting machine 1-2 are producing SPHC steel at the same time, the casting speed of the first continuous casting machine 1-1 is 1.0m / min. The prediction model of the billet heating and holding time in the furnace determines that the heating time of the hot-charged slab in the furnace is 90 minutes. Taking into account other uncertain facto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com