Drilling machine with cooling liquid splash-proof function

A cooling liquid and functional technology, applied to the parts of boring machine/drilling machine, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of invalid use, waste, and affecting cooling effect of cooling liquid, so as to prevent splashing and facilitate recycling , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

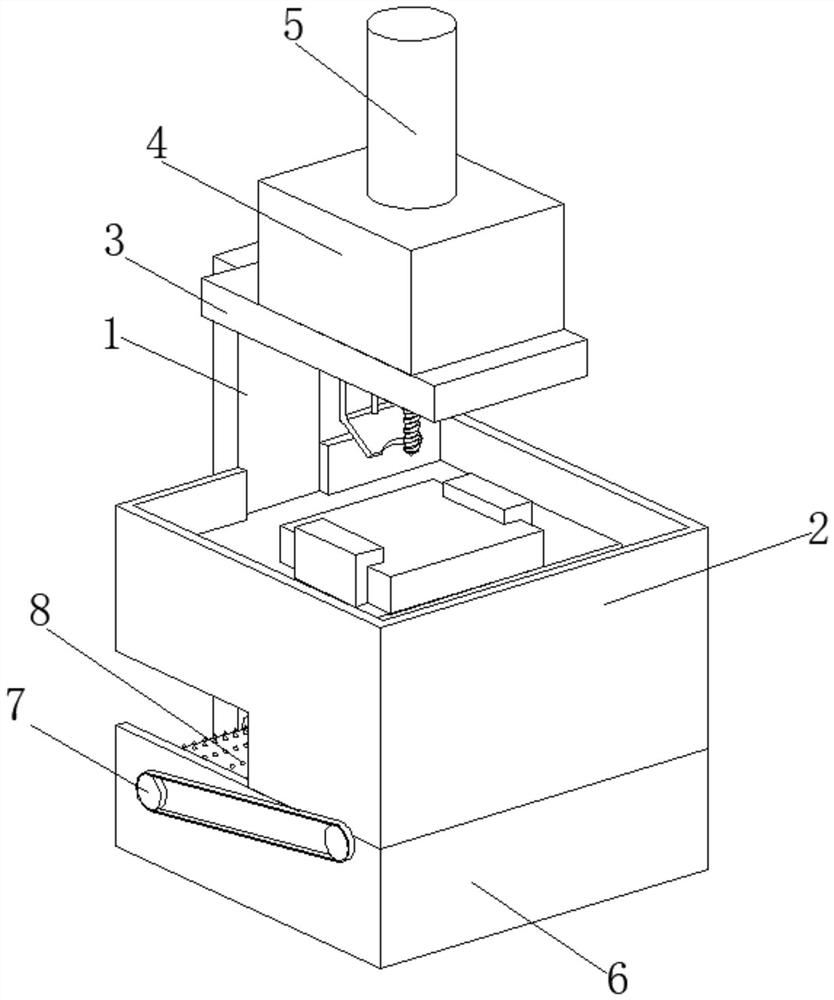

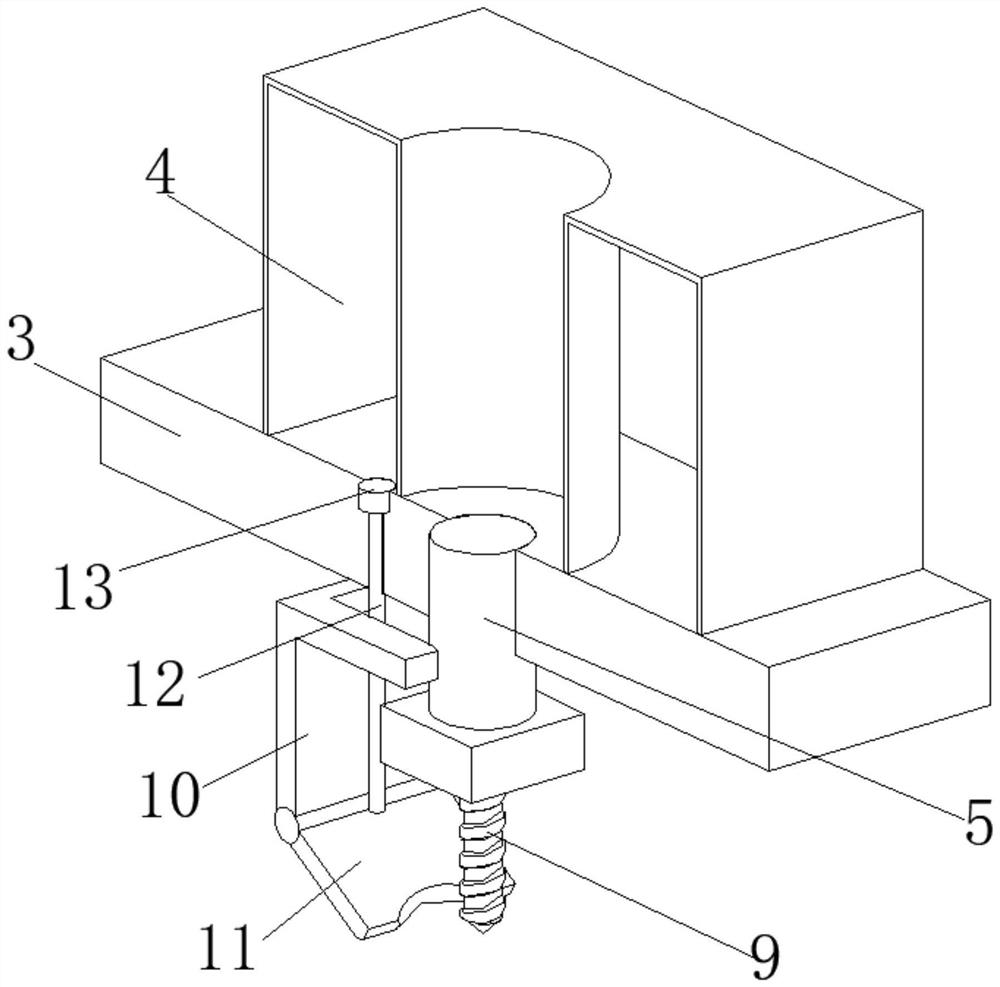

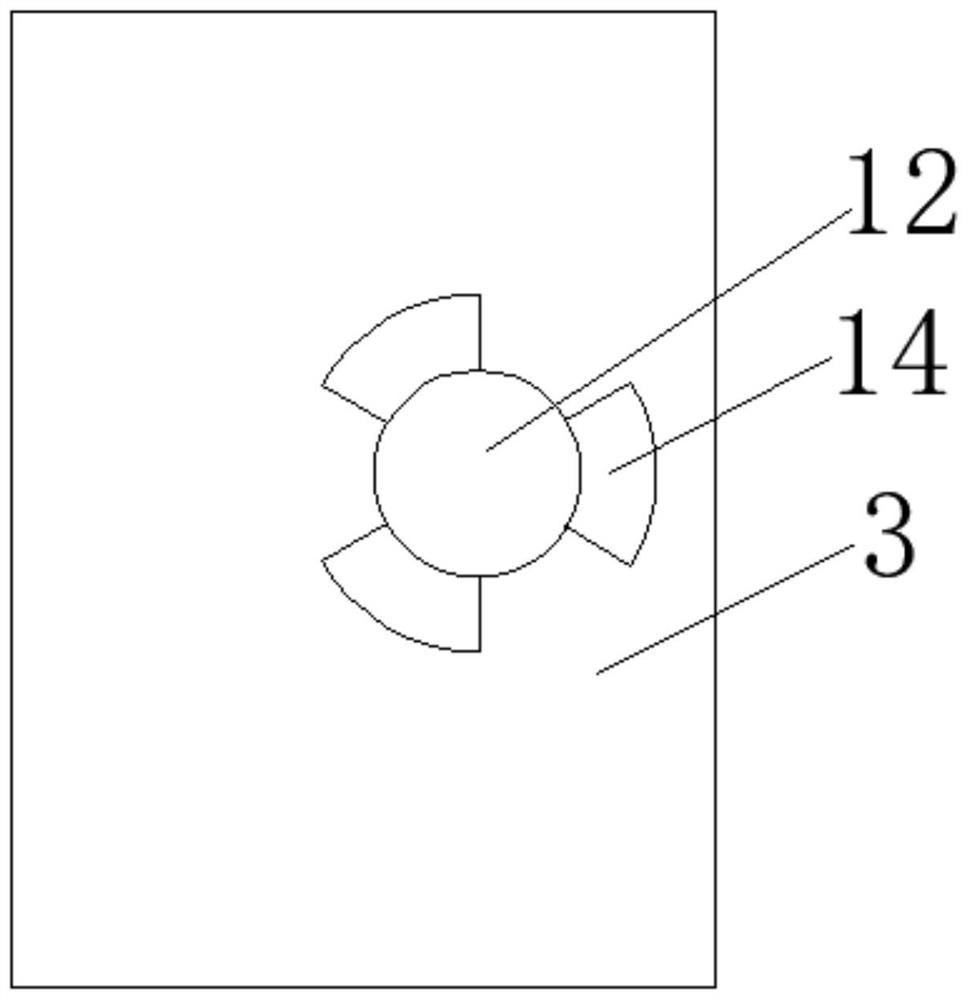

[0028] A drill press with coolant splash protection, such as Figure 1-Figure 6 As shown, including the support plate 1, the front part of the support plate 1 is fixedly connected with the installation plate 3 and the workbench 2 respectively, and the workbench 2 is located under the installation plate 3, and the top of the installation plate 3 is respectively installed with a water tank 4 and an oil cylinder 5 , and the surface of the oil cylinder 5 is in contact with the inner wall of the water tank 4, the output end of the oil cylinder 5 is fixedly connected with the drilling machine 9 and the fixed plate 10 respectively, and the bottom of the fixed plate 10 is connected with the rotating plate 11 through the rotation of the torsion spring, and the inner wall of the mounting plate 3 A guide rod 12 is slidably connected, and the top of the guide rod 12 is fixedly connected with a limit plate 13. The inside of the mounting plate 3 is provided with a drainage hole 14, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com