Cutting mechanism for pipe fitting cutting machine

A cutting mechanism and cutting machine technology, applied in maintenance and safety accessories, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of pipe incision accuracy not meeting design requirements, manual grinding, and large vibration of the blade. Improve assembly stability, improve incision accuracy, and improve the effect of clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

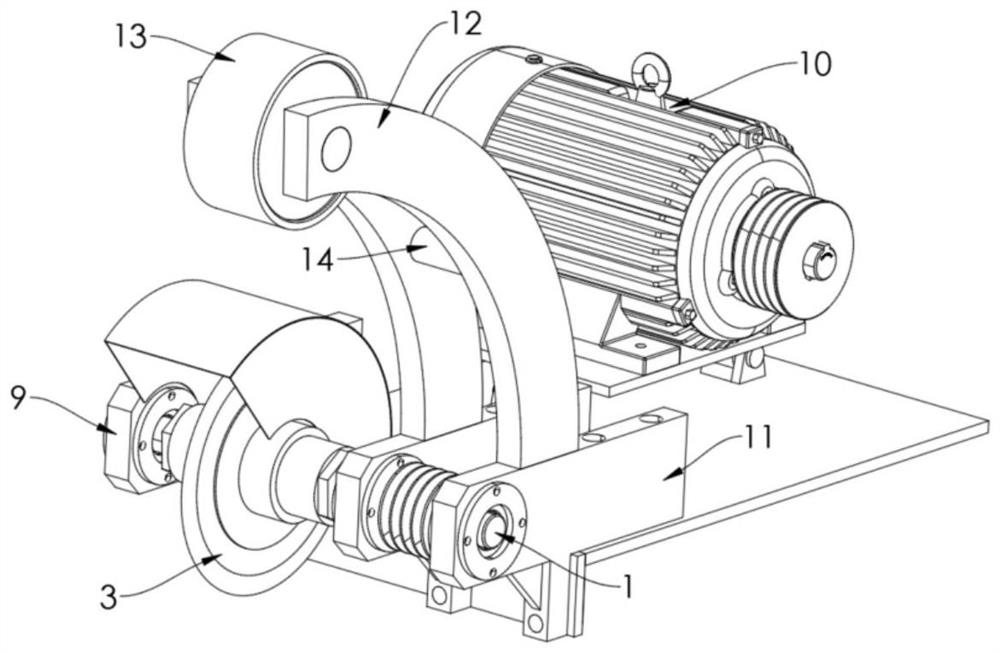

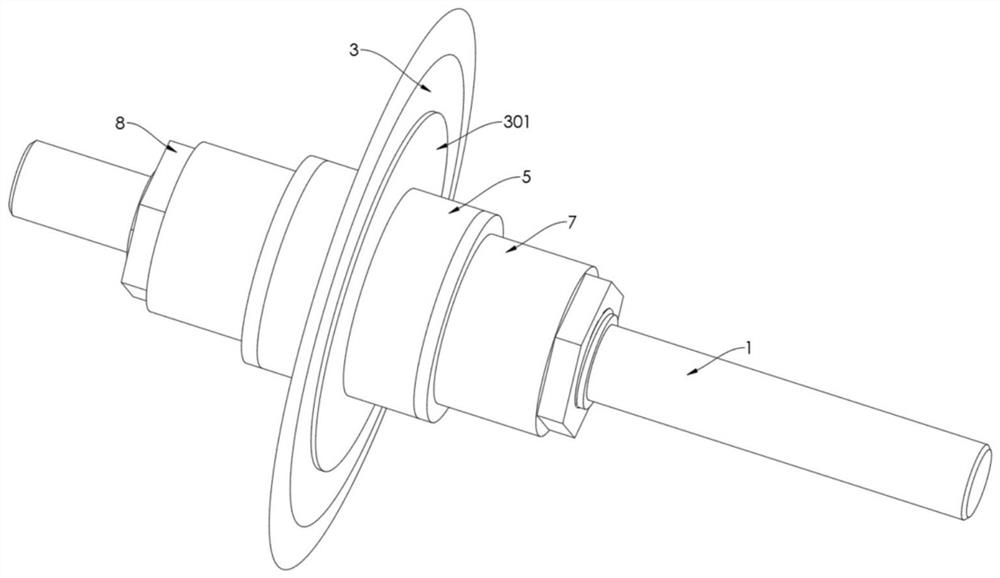

[0036] refer to Figure 1-9 , a cutting mechanism for a pipe cutting machine, comprising

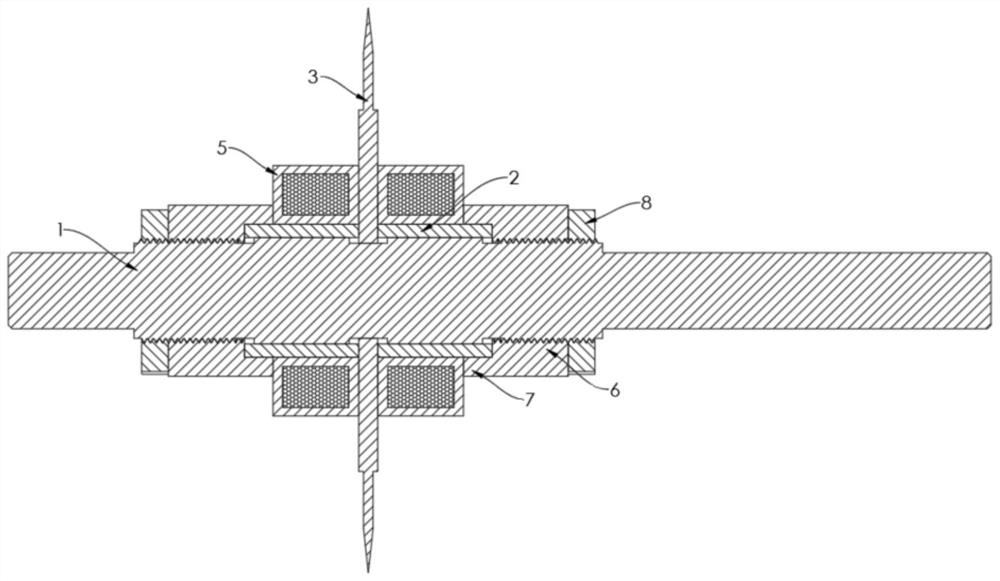

[0037] The blade installation shaft 1, the two sides of the blade installation shaft 1 are respectively integrally formed and outwardly provided with several fixed keys 101 arranged at equal angles;

[0038]A group of plug-in pipe fittings 2, the inner side walls of the plug-in pipe fittings 2 are respectively provided with corresponding fixing grooves 201 at positions corresponding to the fixing keys 101, and the group of plug-in pipe fittings 2 Respectively movably mounted on both sides of the blade installation shaft 1, the set of plug-in pipes 2 are respectively fixed and locked by corresponding fixed locking mechanisms, and the inner ends of the plug-in pipes 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com