Rapid cooling device for injection molding product processing

A technology for rapid cooling and injection molding products, used in transportation and packaging, separation methods, and dispersed particle separation, which can solve problems such as waste and multiple water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

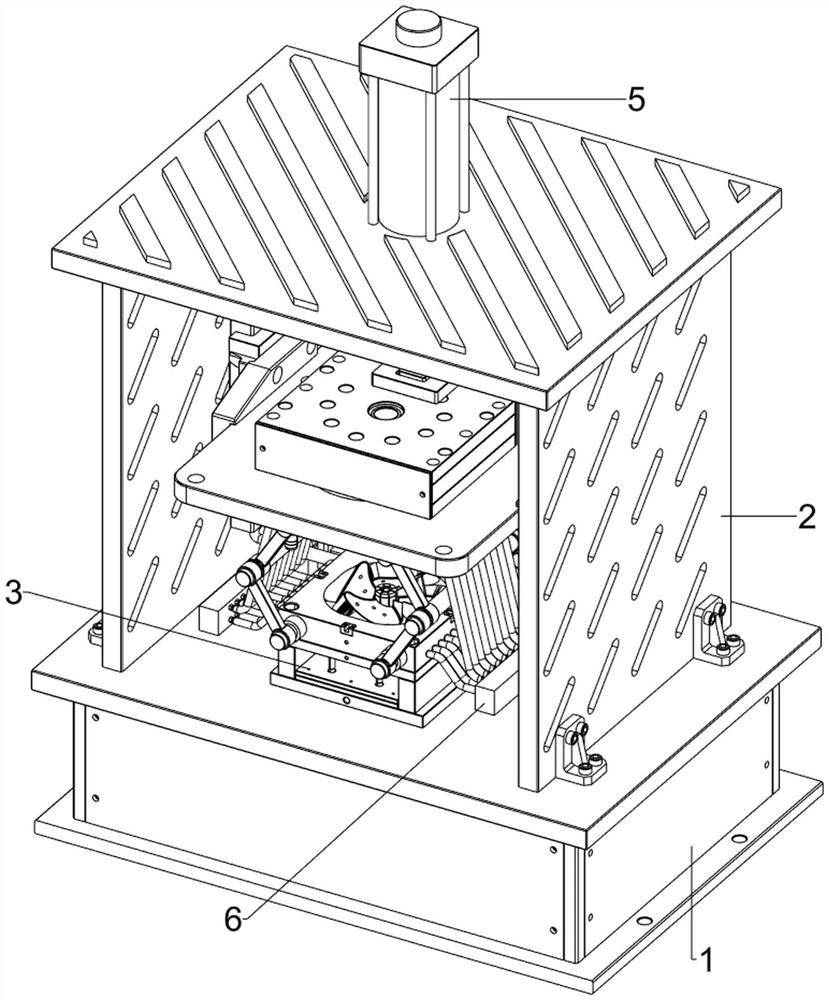

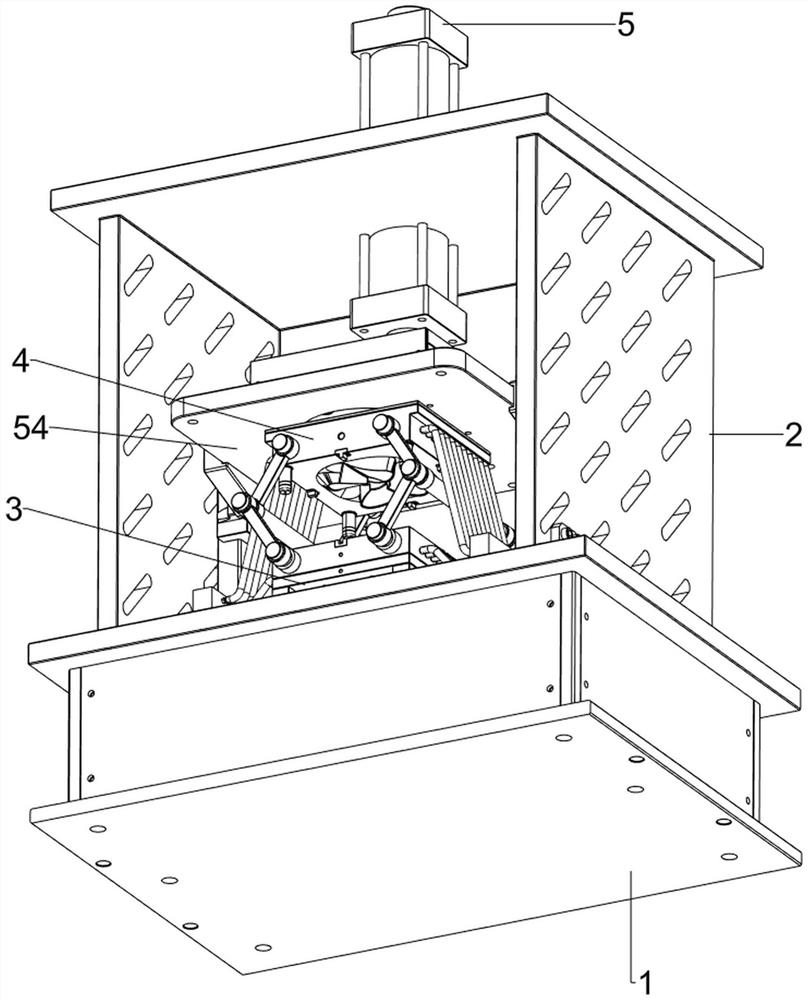

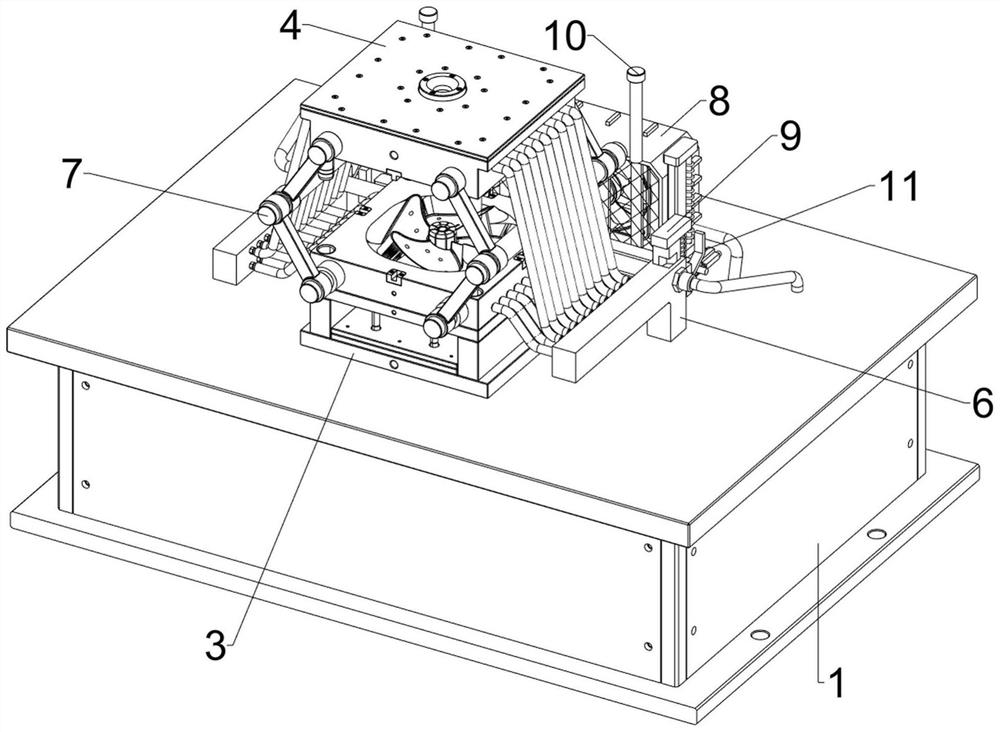

[0039] A rapid cooling device for processing injection molded products, refer to Figure 1-Figure 8 , including a base 1, a fixed frame 2, a bottom mold 3, a top mold 4, a lifting mechanism 5 and a cooling mechanism 6, the top of the base 1 is welded with a fixed frame 2, the top of the base 1 is provided with a bottom mold 3 in the middle, and the bottom mold 3 Located inside the fixed frame 2, the upper part of the fixed frame 2 is provided with a lifting mechanism 5, and the lifting mechanism 5 is provided with a top mold 4. The top mold 4 is located directly above the bottom mold 3, and the top mold 4 can be in contact with the bottom mold 3 when moving downward. together, so that the raw material can be shaped, and the base 1 is provided with a cooling mechanism 6 inside.

[0040] refer to figure 1 , figure 2 , Figure 4 and Figure 5, the lifting mechanism 5 includes a hydraulic cylinder 51, the first slide rail 52, a sliding frame 53 and a fixed plate 54, the upper...

Embodiment 2

[0044] On the basis of embodiment 1, refer to image 3 and Figure 9 , also includes a stretching mechanism 7, and the stretching mechanism 7 includes a first connecting block 71, a second connecting block 72, a connecting rod 73 and a first ejector rod 74, and the front and rear sides of the top mold 4 are welded symmetrically to the left and right. A connection block 71, the front and rear sides of the bottom mold 3 are welded symmetrically with the second connection block 72, the first connection block 71 and the second connection block 72 are all rotatably provided with connecting rods 73, and the four corresponding connecting rods in the front and back The inner sides of the rods 73 are all rotatably provided with first push rods 74, and the first push rods 74 are all in contact with the adjacent third conduits 64. When the first push rods 74 move outward, the third conduits 64 can be pushed away. , to prevent the third conduit 64 from entering between the top mold 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com