High-strength tear-resistant PE (polyethylene) film as well as preparation method and application thereof

A density and medium density technology, applied in the field of packaging materials, can solve the problems of large loss and labor, and achieve the effect of high tensile strength and good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

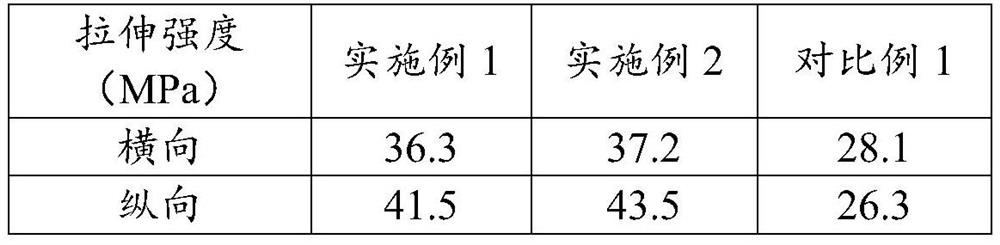

Examples

Embodiment 1

[0032] This embodiment provides a high-strength, tear-resistant PE film, which sequentially includes an inner layer, a middle layer, and an outer layer, and the thicknesses of each layer are 15 μm, 30 μm, and 15 μm, respectively.

[0033] The inner layer comprises the following raw materials in parts by weight: 43.2 parts of linear low-density polyethylene, 20 parts of low-density polyethylene, 35 parts of the first metallocene polyethylene, 1.5 parts of opening (smooth) agent, polyphthalamide ( PPA) 0.3 parts;

[0034] The middle layer includes the following raw materials in the following parts by weight: 19.5 parts of the second metallocene polyethylene, 30 parts of medium-density polyethylene, 50 parts of high-density polyethylene, and 0.5 parts of polyphthalamide (PPA);

[0035] The outer layer includes the following raw materials in parts by weight: 29.5 parts of the second metallocene polyethylene, 50 parts of medium-density polyethylene, 20 parts of low-density polyethy...

Embodiment 2

[0050] This embodiment provides a high-strength, tear-resistant PE film, which sequentially includes an inner layer, a middle layer, and an outer layer, and the thicknesses of each layer are 15 μm, 30 μm, and 15 μm, respectively.

[0051] The inner layer includes the following raw materials in parts by weight: 43 parts of linear low-density polyethylene, 20 parts of low-density polyethylene, 35.3 parts of the first metallocene polyethylene, 1.5 parts of opening (smooth) agent, polyphthalamide ( PPA) 0.2 copies;

[0052] The middle layer includes the following raw materials in the following parts by weight: 19 parts of the second metallocene polyethylene, 30.5 parts of medium-density polyethylene, 50 parts of high-density polyethylene, and 0.5 parts of polyphthalamide (PPA);

[0053] The outer layer includes the following raw materials in the following parts by weight: 29 parts of the second metallocene polyethylene, 50 parts of medium-density polyethylene, 20 parts of low-dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com