Efficient stripping device for optical thin film production

A technology of optical film and stripping device, which is applied in the direction of layered products, chemical instruments and methods, lamination, etc., can solve the problems affecting the stripping efficiency of optical films and the lack of experimental variables, so as to shorten the preparation time, increase experimental variables and experiment The effect of data, good experimental analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

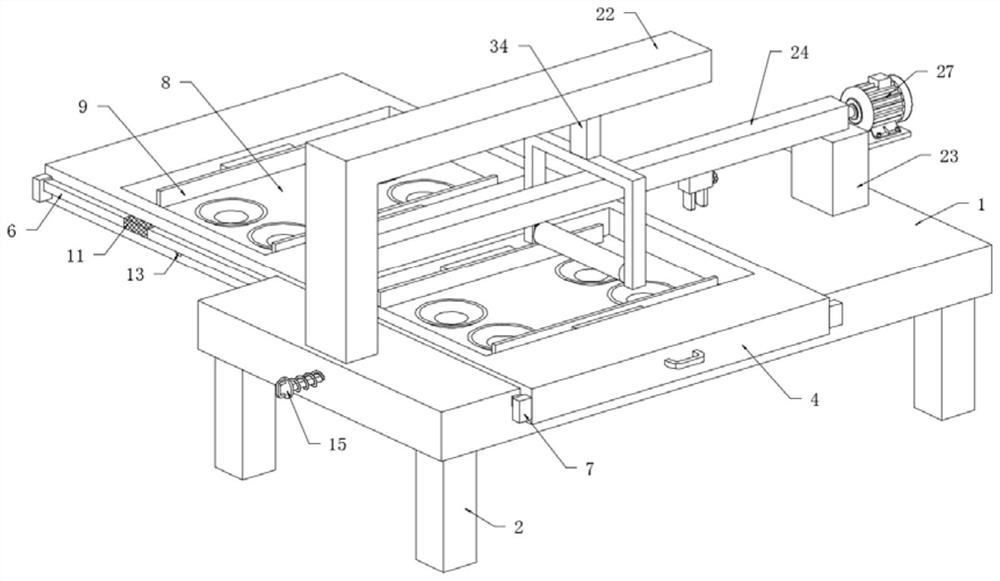

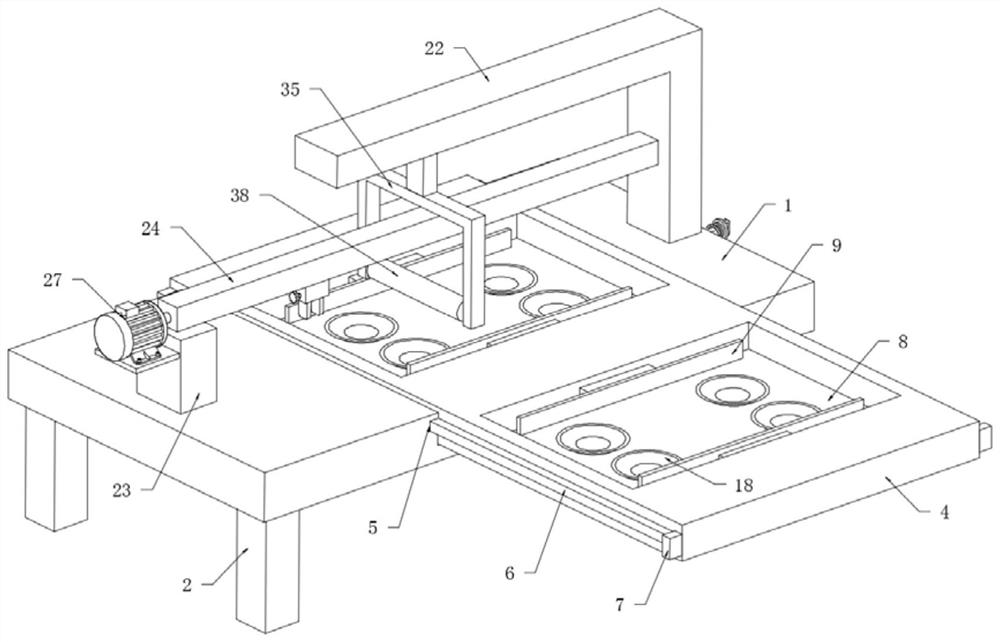

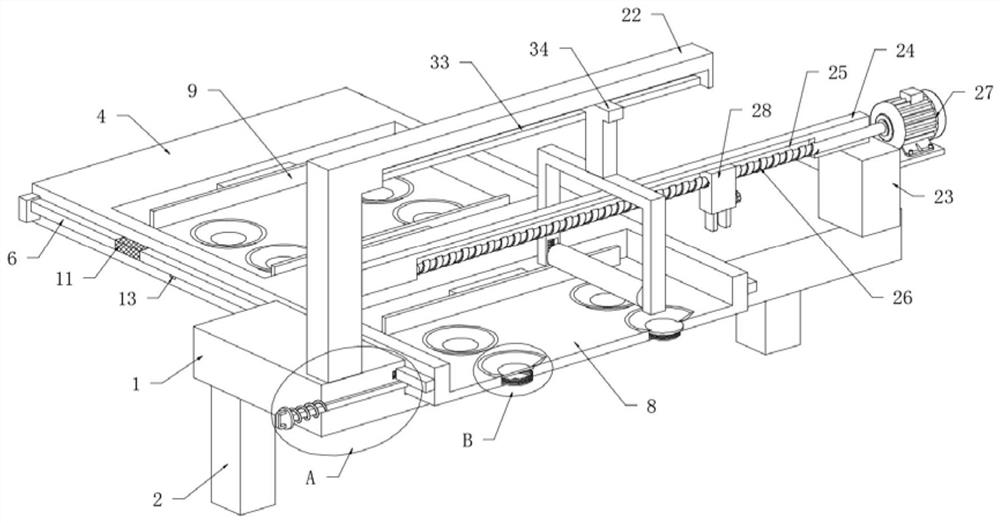

[0029] refer to Figure 1-5 , a high-efficiency peeling device for optical film production, comprising an operating table 1 and a moving plate 4, the bottom of the operating table 1 is fixedly connected with a plurality of supporting feet 2, and the operating table 1 is provided with a penetrating moving groove 3, and the moving plate 4 and the moving plate The groove 3 is slidingly connected, and symmetrical slide grooves 5 are provided on the groove walls on both sides of the moving groove 3, and a slide rail 6 is fixedly connected to each side of the moving plate 4. The chute 5 is slidably connected, the two ends of each slide rail 6 are fixedly connected with the limit block 7, and one end of the moving plate 4 is fixedly connected with a handle.

[0030] The upper end surface of the moving plate 4 is provided with two symmetrical placing grooves 8, and the groove walls on both sides of each placing groove 8 are provided with electric splints 9, and the moving plate 4 is p...

Embodiment 2

[0034] refer to Figure 6-8 A further improvement is made on the basis of Embodiment 1. An electromagnetic plate 10 is embedded in the bottom of the moving slot 3, and two separate The conductive block 12 is embedded with two conductive layers 11 on the slide rail 6. The positions of the two conductive layers 11 correspond to the two placement slots 8 respectively. The two conductive blocks 12 are connected in series with the electromagnetic board 10 through wires and connected to the outside world The power supply is electrically connected, and a plurality of grooves 17 are evenly opened on the bottom groove wall of each placement groove 8, and a suction cup 18 is fixedly connected to the notch of each groove 17, and the sealed sliding connection belt in the groove 17 is formed by a magnetic piston. The plate 19 and the bottom of the piston plate 19 are fixedly connected with a second spring 20 , and the lower end of the second spring 20 is fixedly connected with the bottom g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com