Glass carrying protection device for building decoration

A protection device, glass technology, applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of high labor intensity, low efficiency, glass damage due to shaking, etc., to achieve convenient movement, prevent shaking and falling, and protect glass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

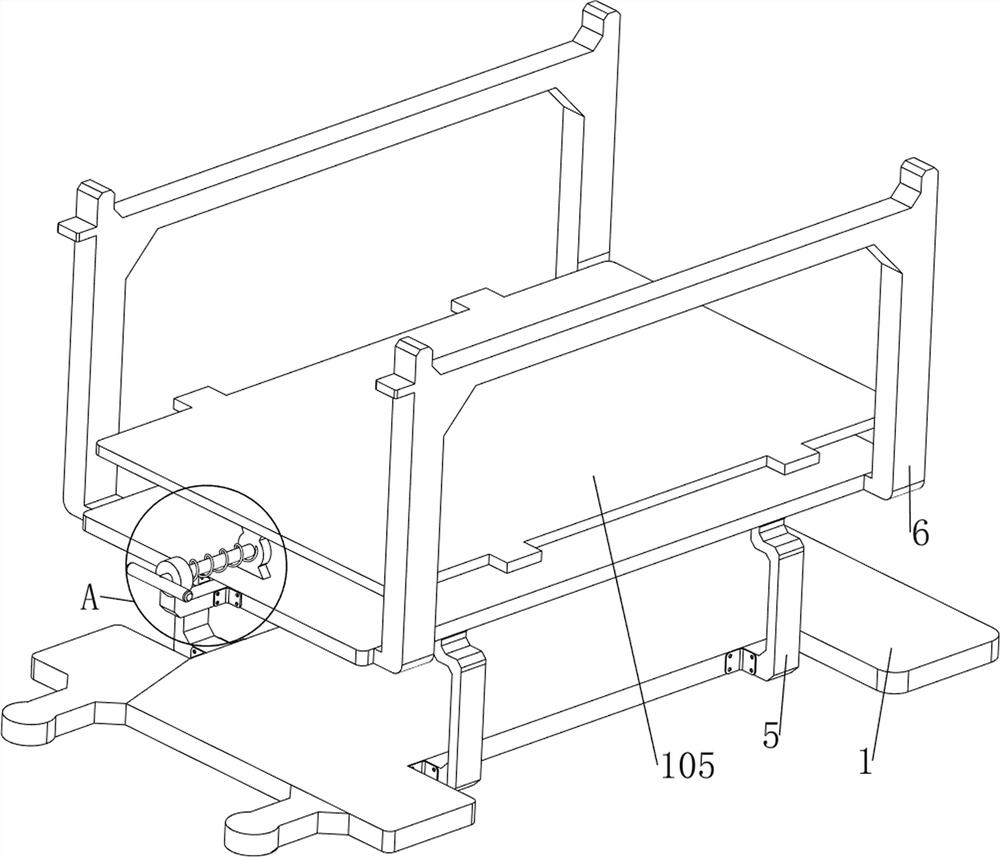

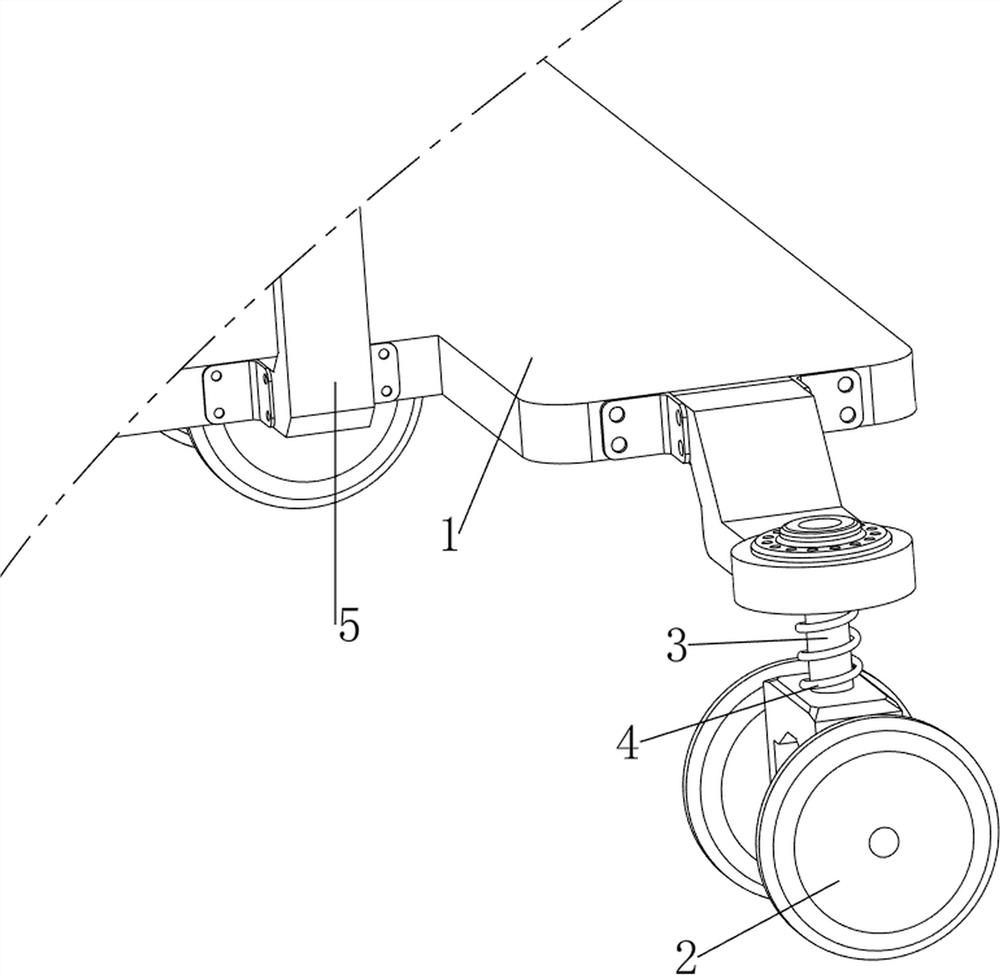

[0036] A glass handling protective device for building decoration, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 12 As shown, it includes a fixed plate 1, a wheel 2, a steering rod 3, a first spring 4, a support rod 5, a placement frame 6, a push rod 7, a guide mechanism 13, a protective mechanism 8 and a clamping mechanism 9, and the bottom of the fixed plate 1 The front and rear sides are left and right symmetrically sliding with steering rods 3, and the bottoms of the four steering rods 3 are all rotatable. Wheels 2 are provided to make the device move more conveniently. The four steering rods 3 are connected to the fixed plate 1. There are first springs 4 for buffering the wheels 2, and the front and rear sides of the fixed plate 1 are symmetrically provided with support rods 5, and the four support rods 5 are all located in the inner position between the four wheels 2. A placement frame 6 for placing glass is placed between ...

Embodiment 2

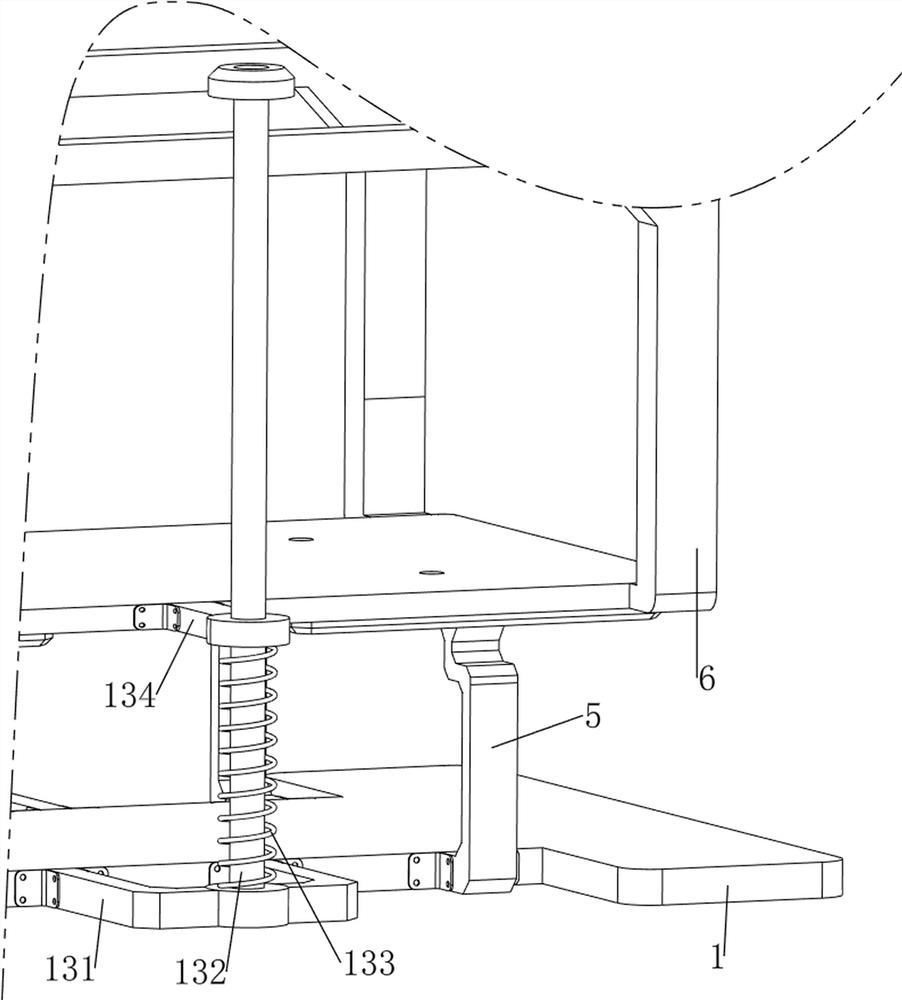

[0042] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 13 with Figure 14 As shown, a buffer mechanism 10 is also included. The buffer mechanism 10 includes a second fixed mount 101, a second connecting rod 102, a third connecting rod 103, a fourth spring 104 and a buffer plate 105. The front and back are symmetrically welded with a second fixed mount 101, and the four second fixed mounts 101 are slidably provided with a third connecting rod 103, and the four third connecting rods 103 are all slidably connected with the placement frame 6. The second connecting rods 102 are connected between the bottoms of the third connecting rods 103, and the two second connecting rods 102 are all in contact with the second fixed frame 101 on the same side, and the tops of the four third connecting rods 103 are connected with Place the buffer plate 105 of glass, the fourth spring 104 is connected between the front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com