Flammulina velutipes polysaccharide-soybean protein gel suitable for 3D printing and preparation method thereof

A technology of soybean protein gel and Flammulina velutipes polysaccharide, applied in biochemical equipment and methods, fixed on/in organic carriers, food science and other directions, can solve problems such as uneasy acceptance by consumers, complicated operation process, etc. Effects of insufficient protein intake, uniform texture, and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

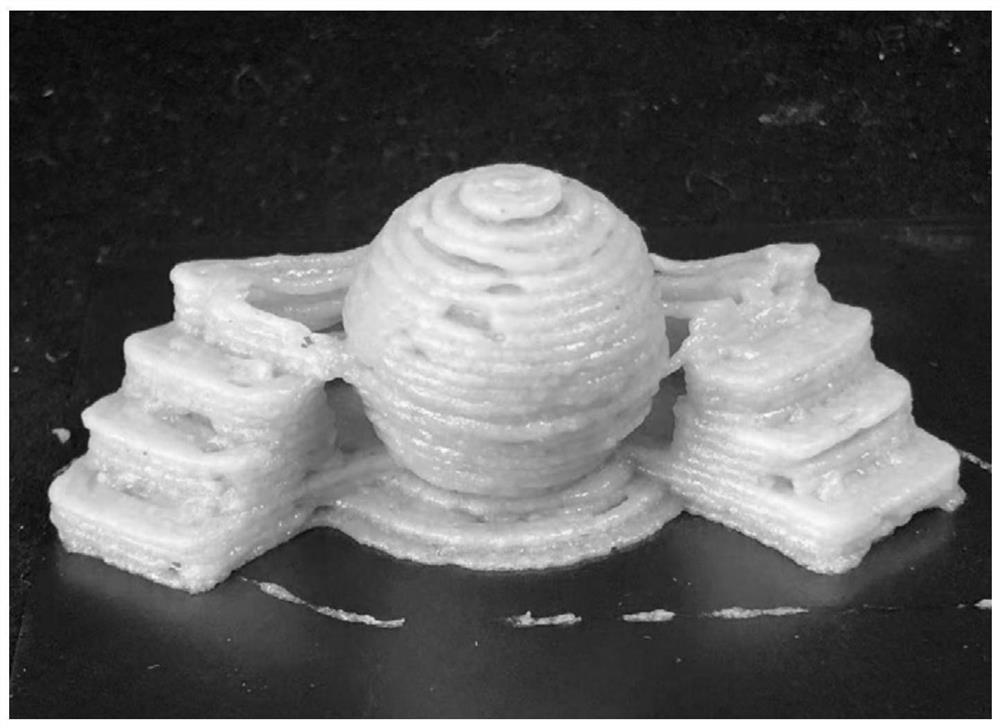

Image

Examples

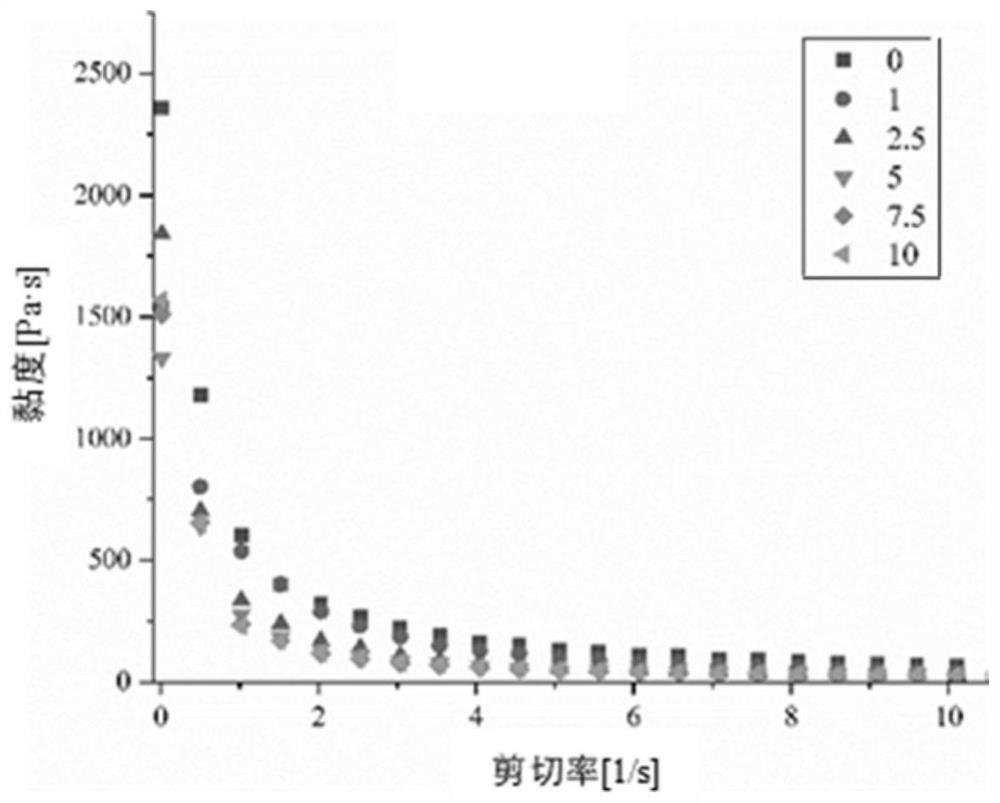

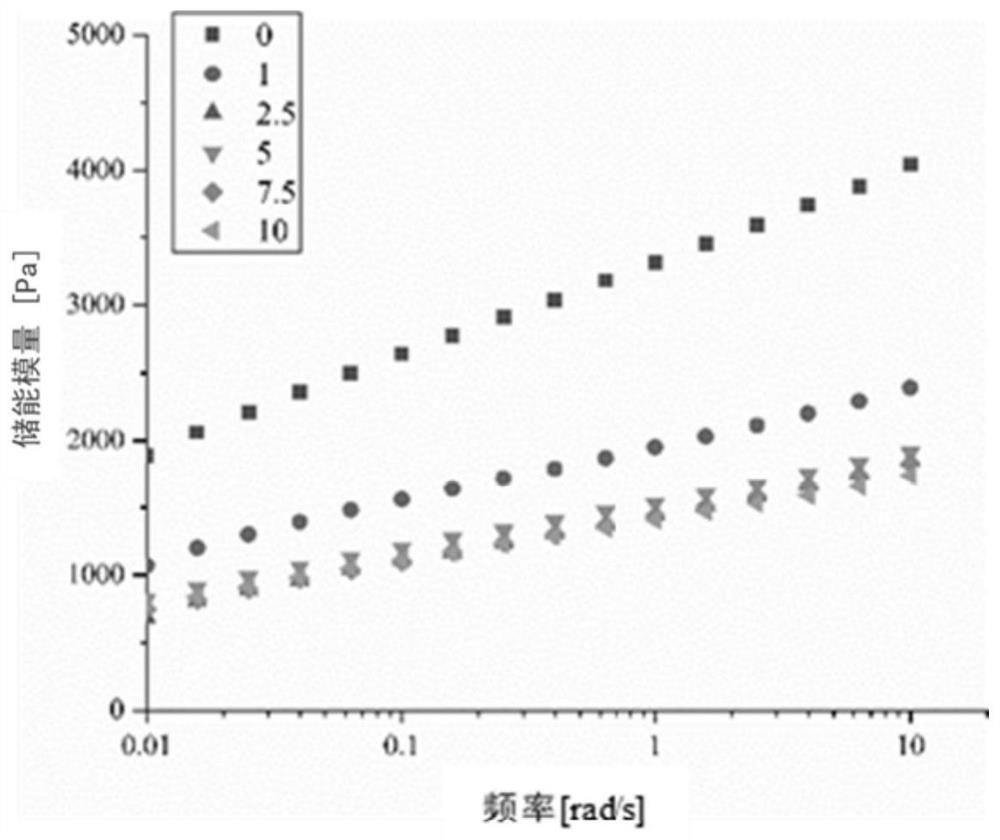

Embodiment 1

[0049] The preparation of Flammulina velutipes polysaccharide-soybean protein gel suitable for 3D printing, the specific steps are as follows:

[0050] Step (1), pretreatment: prepare concentration 0.167% Flammulina velutipes polysaccharide aqueous solution, add soybean protein in Flammulina velutipes polysaccharide aqueous solution, fully stir 30min with rotating speed 300rpm to evenly make the total mass volume concentration of soybean protein and Flammulina velutipes polysaccharide (g / ml, The same below) is 16.67%. At this time, the quality of Flammulina velutipes polysaccharides accounts for 1% of the total mass of soybean protein and Flammulina velutipes polysaccharides. Soybean protein and Flammulina velutipes polysaccharide aqueous solution are mixed until uniform to obtain polysaccharide-protein cold gel;

[0051] Step (2), heating: heat the protein-polysaccharide cold gel in a 90°C water bath for 30 minutes to obtain a polysaccharide-protein thermal mixture;

[0052] ...

Embodiment 2

[0054] The preparation of Flammulina velutipes polysaccharide-composite gel suitable for 3D printing, the specific steps are as follows:

[0055] Step (1), pretreatment: prepare the aqueous solution of Flammulina velutipes polysaccharide of concentration 0.417%, add soybean protein in Flammulina velutipes polysaccharide aqueous solution, fully stir 30min with rotating speed 300rpm to evenly make the total mass volume concentration of soybean protein and Flammulina velutipes polysaccharide be 16.67%, this When the quality of Flammulina velutipes polysaccharide accounts for 2.5% of the total mass of soybean protein and Flammulina velutipes polysaccharide, soybean protein and Flammulina velutipes polysaccharide aqueous solution are mixed to a uniform polysaccharide-protein cold gel;

[0056] Step (2), heating: heat the protein-polysaccharide cold gel in a 90°C water bath for 30 minutes to obtain a polysaccharide-protein thermal mixture;

[0057] Step (3), cooling: the polysacchar...

Embodiment 3

[0059] The preparation of Flammulina velutipes polysaccharide-soybean protein gel suitable for 3D printing, the specific steps are as follows:

[0060] Step (1), pretreatment: preparation concentration 0.835% Flammulina velutipes polysaccharide aqueous solution, in Flammulina velutipes polysaccharide aqueous solution, add soybean protein, fully stir 30min with rotating speed 300rpm to evenly make the total mass volume concentration of soybean protein and Flammulina velutipes polysaccharide be 16.67%, this When the quality of Flammulina velutipes polysaccharide accounts for 5% of the total mass of soybean protein and Flammulina velutipes polysaccharide, soybean protein and Flammulina velutipes polysaccharide aqueous solution are mixed to a uniform polysaccharide-protein cold gel;

[0061] Step (2), heating: heat the protein-polysaccharide cold gel in a 90°C water bath for 30 minutes to obtain a polysaccharide-protein thermal mixture;

[0062] Step (3), cooling: the polysacchari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com