Preparation method of large hot-forging hot-work die steel

A hot work die steel and hot forging technology, which is applied in the field of large-scale hot forging hot work die steel preparation, can solve the problems of low reliability and service life of the die, complex structure and complex stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

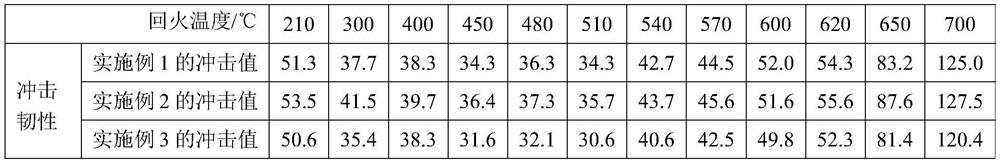

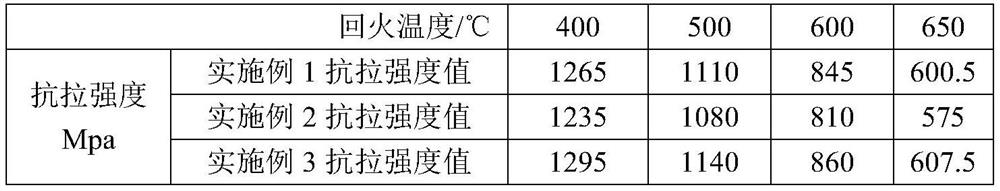

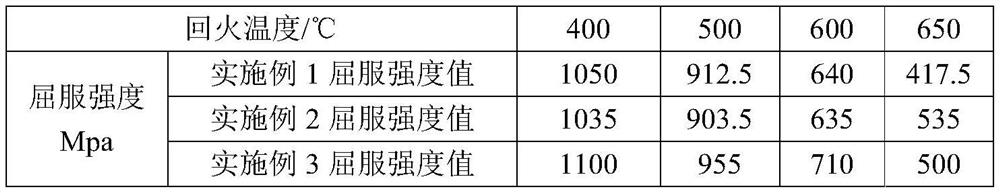

Embodiment 1

[0034] The preparation method of a kind of large-scale hot forging hot working die steel provided in this embodiment comprises the following steps:

[0035] Step 1: use electric furnace, electric furnace + electroslag remelting or vacuum induction furnace to make steel ingots. The chemical composition weight % of steel ingots is: C: 0.38%, Si: 0.44%, S: 0.002%, P: 0.02%, Mn: 0.62%, Mo: 1.51%, Cr: 3.02%, V: 0.15%, Ni: 1.20%, Al+Nb: ≤0.101% (Al: 0.05%; Nb: 0.051%), B: ≤0.07% , the rest is Fe and unavoidable sundries;

[0036] Step 2: Steel ingot pre-opening: The steel ingot is preheated in two stages. First, the temperature is raised to 600°C at a heating rate of 80°C / h for 1 hour, and then the temperature is raised to 800°C at a heating rate of 80°C / h for 1 hour. The heating rate of ℃ / h is raised to 1170 ℃ for 4 hours, and the pliers are pulled out in one direction after being released from the furnace, and the reduction is 8%;

[0037] Step 3: Pre-opening billet high-tempera...

Embodiment 2

[0044] The preparation method of a kind of large-scale hot forging hot working die steel provided in this embodiment comprises the following steps:

[0045] Step 1: Using electric furnace, electric furnace + electroslag remelting or vacuum induction furnace to make steel ingots, the chemical composition weight % of steel ingots is: C: 0.35%, Si: 0.51%, S: 0.002%, P: 0.02%, Mn: 0.52%, Mo: 1.53%, Cr: 3.05%, V: 0.1%, Ni: 0.91%, Al: ≤0.06%, B: ≤0.08%, the rest is Fe and unavoidable impurities;

[0046] Step 2: Steel ingot pre-opening: The steel ingot is preheated in two stages. First, the temperature is raised to 630°C at a heating rate of 70°C / h for 1 hour, and then the temperature is raised to 830°C at a heating rate of 70°C / h for 1 hour. The heating rate of ℃ / h is raised to 1180 ℃ for 5 hours of high-temperature diffusion, and the pliers are pulled out in one direction after being released from the furnace, and the reduction is 7%;

[0047] Step 3: Pre-opening billet high-temp...

Embodiment 3

[0052] The preparation method of a kind of large-scale hot forging hot working die steel provided in this embodiment comprises the following steps:

[0053] Step 1: use electric furnace, electric furnace + electroslag remelting or vacuum induction furnace to make steel ingots. The chemical composition weight % of steel ingots is: C: 0.39%, Si: 0.35%, S: 0.002%, P: 0.02%, Mn: 0.62%, Mo: 1.62%, Cr: 3.38%, V: 0.26%, Ni: 1.12%, Al+Nb: ≤0.0.7% (Al: 0.04%; Nb: 0.067%), B: 0.1 %, the rest is Fe and unavoidable sundries;

[0054] Step 2: Steel ingot pre-opening: The steel ingot is preheated in two stages. First, the temperature is raised to 650°C at a heating rate of 60°C / h for 1 hour, and then the temperature is raised to 850°C at a heating rate of 60°C / h for 1 hour. The heating rate of ℃ / h is raised to 1190 ℃ for 6 hours, and the pliers are pulled out in one direction after being released from the furnace, and the reduction is 6%;

[0055] Step 3: Pre-opening billet high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com