Reinforced concrete box culvert anti-corrosion structure in saline soil area

A reinforced concrete and saline soil technology, applied in the field of professional culverts, can solve the problems of poor stability, water leakage in culverts, increased concrete leaching, etc., achieve stable culvert strength and quality, prevent concrete cracking, slow down speed and concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

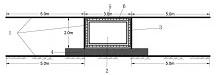

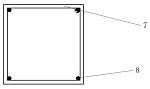

[0021] The reinforced concrete box culvert 2 given in this embodiment is formed by cast-in-place C40 concrete and HRB235 steel bars, and its width and height dimensions are 3.0*2.0m.

[0022] Two cloths and one film 1 are laid on both sides of the wall of the reinforced concrete box culvert 2 to prevent the side walls of the culvert from being corroded by saline soil.

[0023] Two cloths and one membrane 1 are laid on both sides of the top of the reinforced concrete box culvert 2 with roadbed filling, the length is 5.0m, and are tightly welded with the two cloths and one membrane 1 on the outside of the wall to prevent salt from seeping down from the road surface and eroding the culvert.

[0024] A plain concrete cushion 4 is poured under the reinforced concrete box culvert 2 with a thickness of 0.35m. In order to expand the foundation, it mainly serves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com