Control method of equipment for integrally forming internal and external arc-shaped corners of foundation pit and foundation trench

A technology of molding equipment and control methods, which is applied in excavation, infrastructure engineering, construction, etc., and can solve problems such as reduced waterproof performance, easy hollowing, and arc-shaped internal corner damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

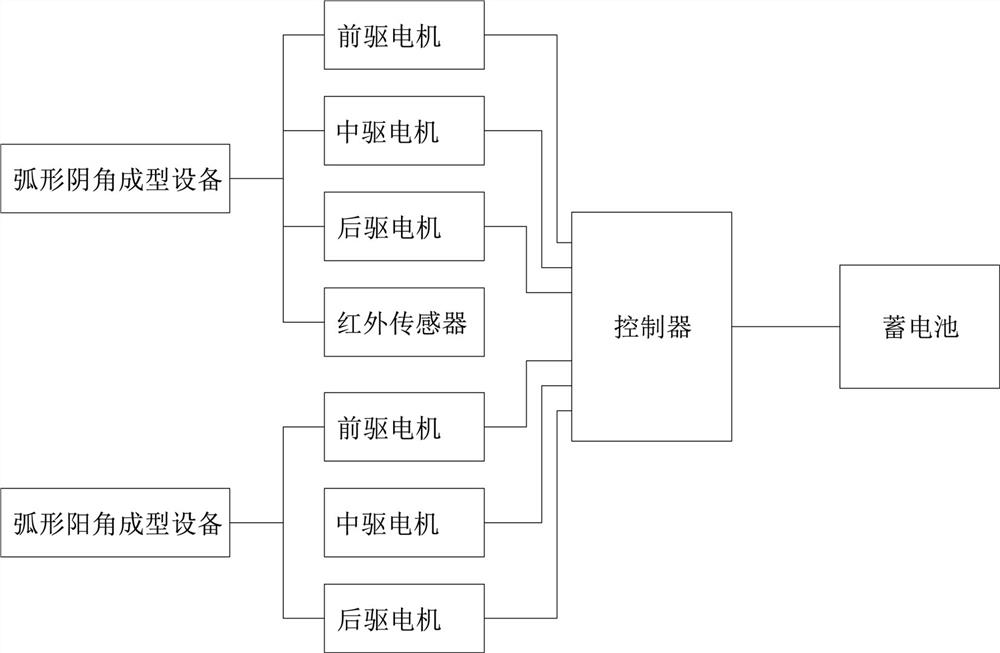

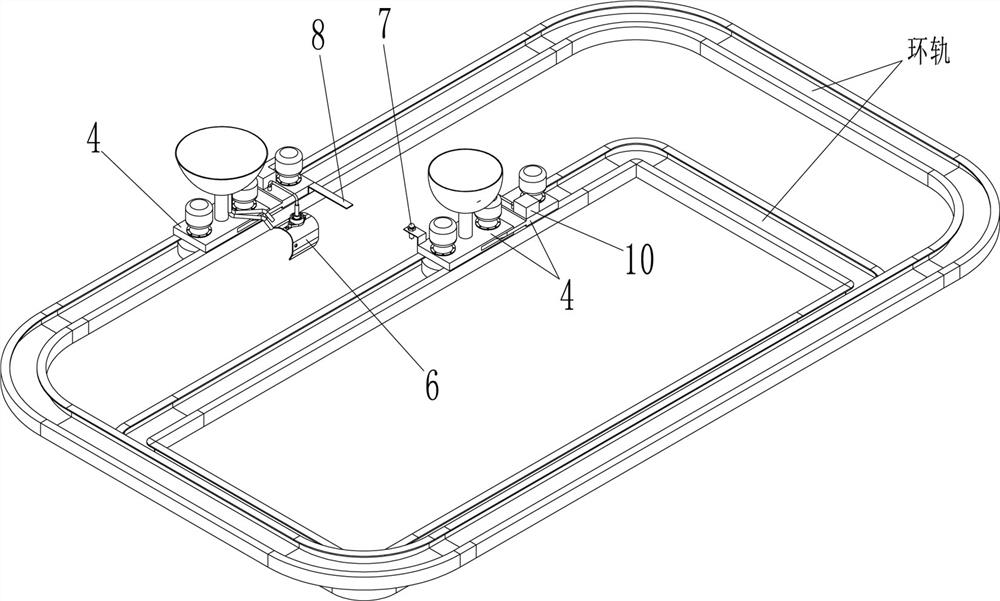

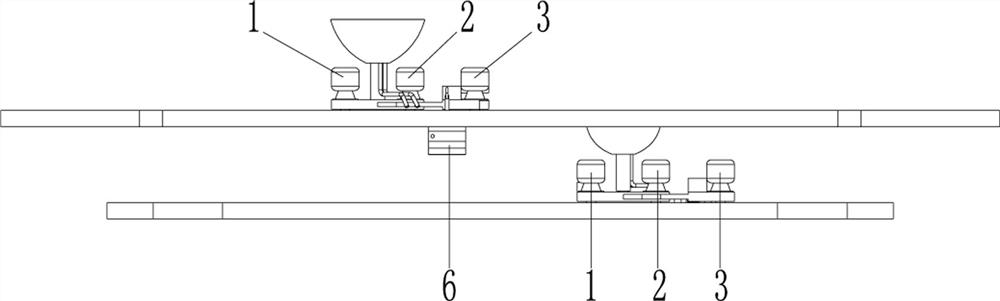

[0032] like Figure 1~Figure 8 Among them, a method for controlling the integrated forming of the Yin and Yang arc corner equipment of the foundation groove of the foundation pit. The female corner mold 5 is located on the outer side of the ring rail and the right-angle female angle in the foundation pit to form a female corner mold groove, and the male corner mold 6 of the arc-shaped male corner forming equipment is located on the inner side of the ring rail and forms a male angle with the right-angle male angle on the foundation pit surface. Die groove; the female corner drive system drives the female corner mold 5 to move along the circular track of the arc-shaped female corner forming equipment, and the male corner drive system drives the male corner mold 6 to move along the circular track of the arc-shaped male corner forming equipment;

[0033] The control method of the inner angle driving system and the outer angle driving system includes the following steps:

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com