Heat-insulating cold-rolled steel door and production device thereof

A technology for heat insulation and production equipment, which is applied in the direction of sealing devices, door leaves, windows/doors, etc. It can solve the problems of increasing the weight of cold-rolled steel doors, overfilling and dense filling, and achieves improved filling quality and heat preservation performance, improve service life, and ensure the effect of heat insulation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

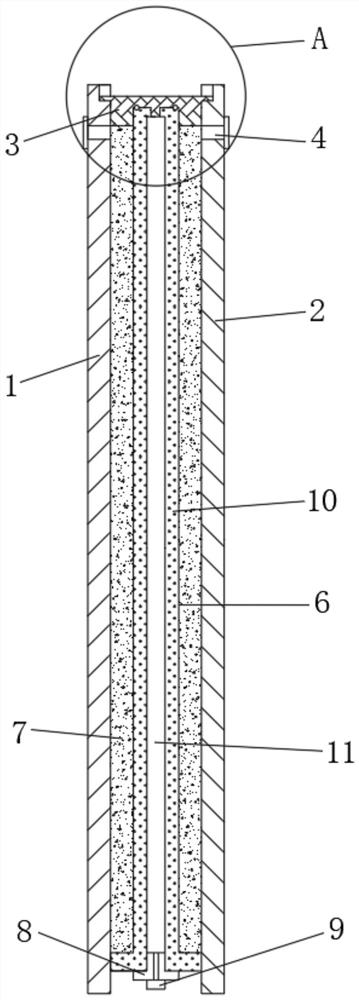

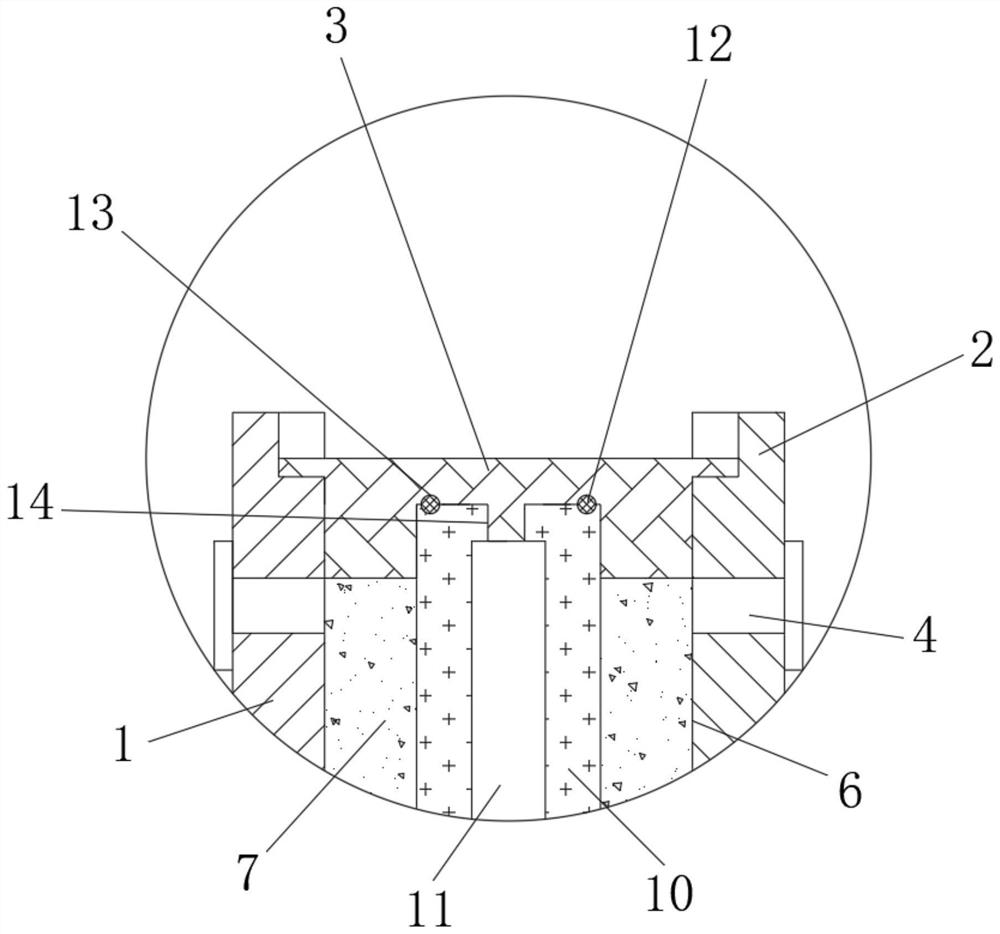

[0052] Embodiment 1: For the filling production process of the cold-rolled steel door with a relatively short filling cavity 6, a single extrusion is used for compaction.

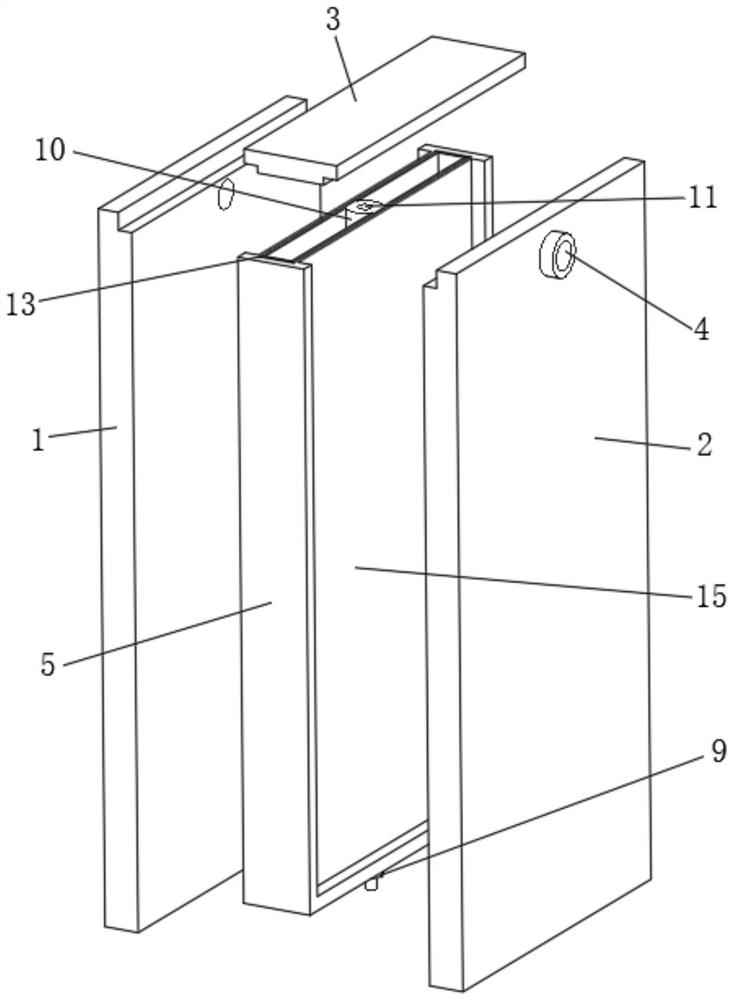

[0053] Through the cooperation of the clamping plate 18 and the fastener 19, the end of the cold-rolled steel door is clamped and fixed, and the convenient connection with the regulating air pump 20 is realized by setting the inner liner 10 with the connecting valve 9 , by adjusting the air pump 20 to drive the piston 28 in the lifting cavity 11, to drive the extruding rod 25 and the active rod 26 to slide back and forth, and by setting the slider 29 to cooperate with the chute 24, the sliding of the slide plate 22 is realized The positions are relative to ensure that the sliding plate 22 keeps sliding in parallel, so that the filling and pressing device 27 maintains a stable extrusion in the filling cavity 6, and the filling cavity 6 is filled with material by setting the filling port 4 and the feed pump 21...

Embodiment 2

[0054] Embodiment 2: When the filling length of the cold-rolled steel door is long, the filling port 4 is used to realize the filling and extrusion of multiple batches in sections. During the filling and driving process, the air intake is controlled by adjusting the air pump 20, so as to achieve the adjustment of driving and extrusion. The purpose of pressing the distance is to ensure the dense filling of the filler, thereby improving the filling quality and thermal insulation performance

Embodiment 3

[0055] Embodiment 3: Due to the deviation in the amount of the heat-insulating filler 7 entering once, there is also a deviation in the adjustment of the intake air volume of the air pump 20, which may easily cause the extrusion driving distance to be insufficient or too long. When the extrusion distance is insufficient, it cannot To achieve tight compaction, when the extrusion distance is too long, it is easy to cause the rod to break due to extrusion.

[0056] By setting the cooperation between the fixed plate 32 and the pressing plate 33 that can be extruded, in the error range where the extruding distance is insufficient or too long, the compression amount of the spring 30 is used for buffering, so that the clamping distance driven by the air pump 20 and the filling ratio can be adjusted. The width is adapted to achieve the purpose of improving the quality of filling compaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com