Deep coal in-situ fluidized mining method based on heat extraction and power generation

A mining method and coal technology, applied in coal gasification, mining fluid, mining equipment, etc., can solve problems such as environmental pollution, low development efficiency, frequent safety accidents, etc., and achieve reuse, increase temperature, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] The invention provides a deep coal in-situ fluidized mining method based on heat extraction and power generation, which specifically includes the following steps;

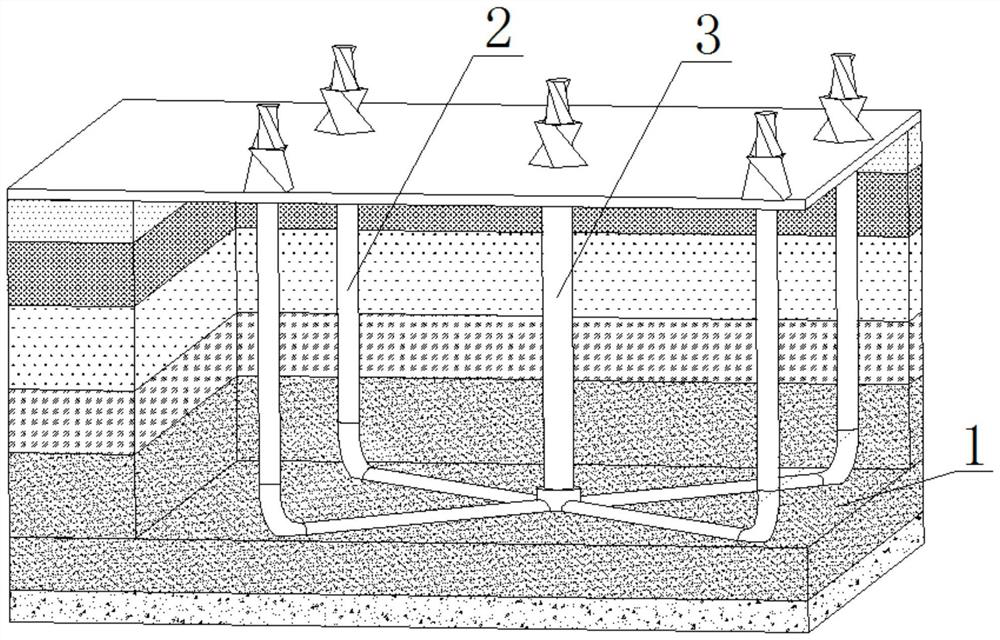

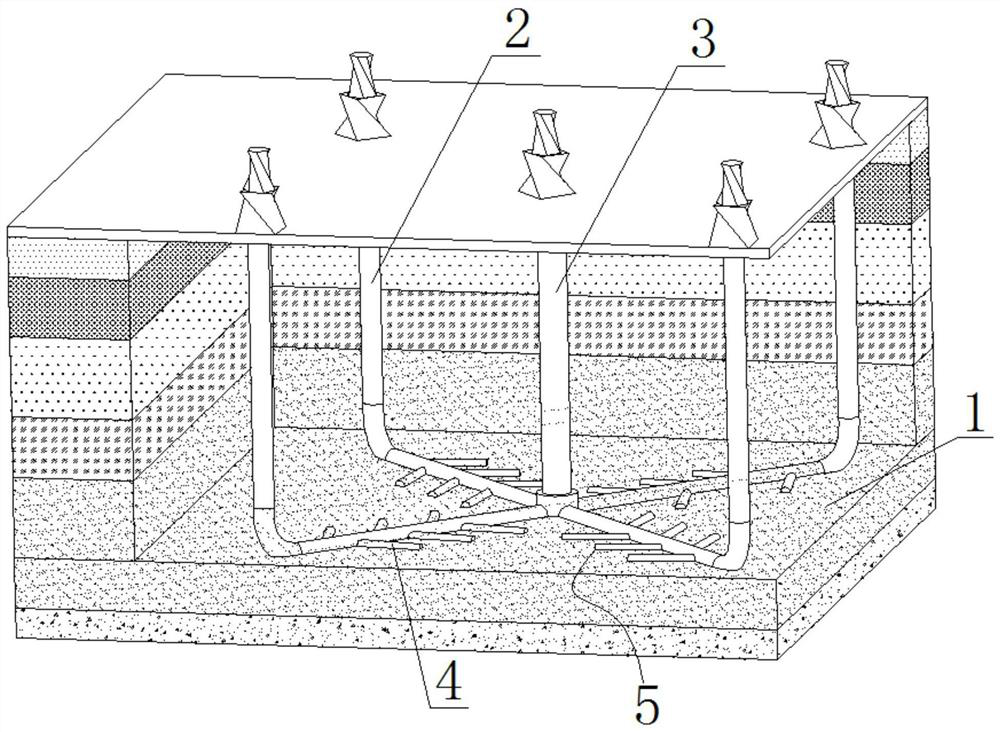

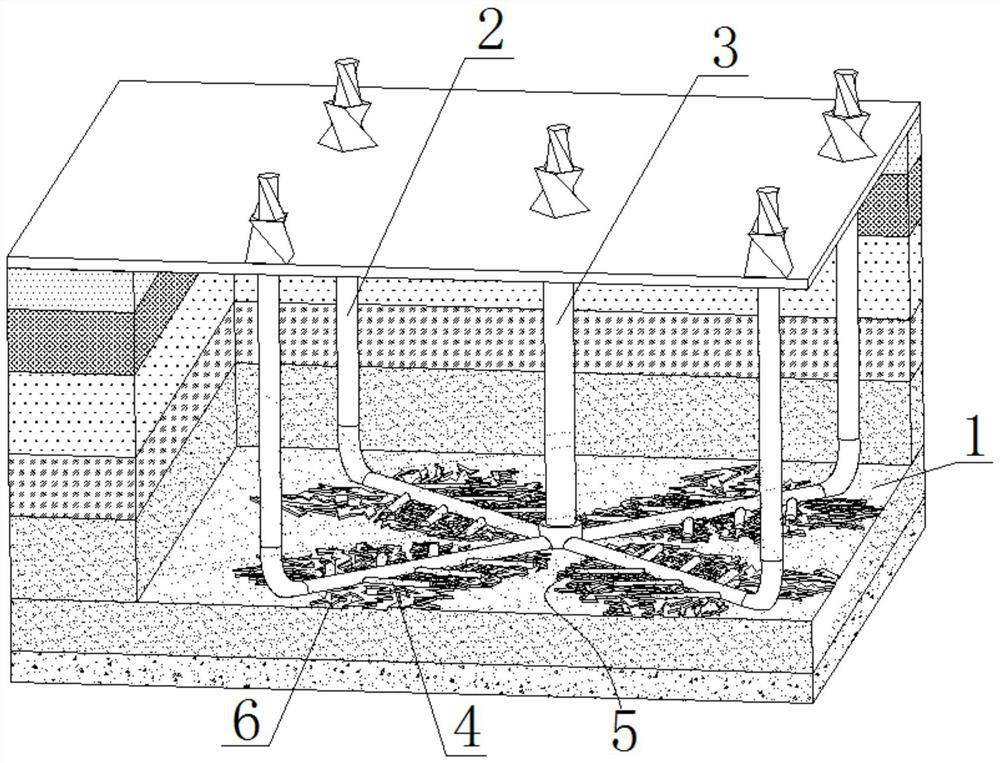

[0040] Step 1: Construct a multi-plane U-shaped well;

[0041] First, according to the geological parameters and exploration data of the underground coal seam, the coal seam 1 that needs fluidized mining is determined, and then the well pattern is arranged in the coal seam 1, such as figure 1 As shown, the well pattern is composed of a vertical well 3 arranged in the center of the coal seam 1 and several horizontal wells 2 evenly distributed around the vertical well 3 in the circumferential direction, wherein the end of the vertical well 3 extends to near the bottom of the coal seam 1, and the horizontal wells 2 It passes through the bottom of the coal seam 1, and its end communicates with the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com