Portable multi-working-condition universal shaft calibration device

A multi-working-condition, portable technology, applied in the direction of guidance, offensive equipment, weapon accessories, etc., can solve the problems of remote target finding being limited by terrain, inapplicability, and unusable lasers, etc. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

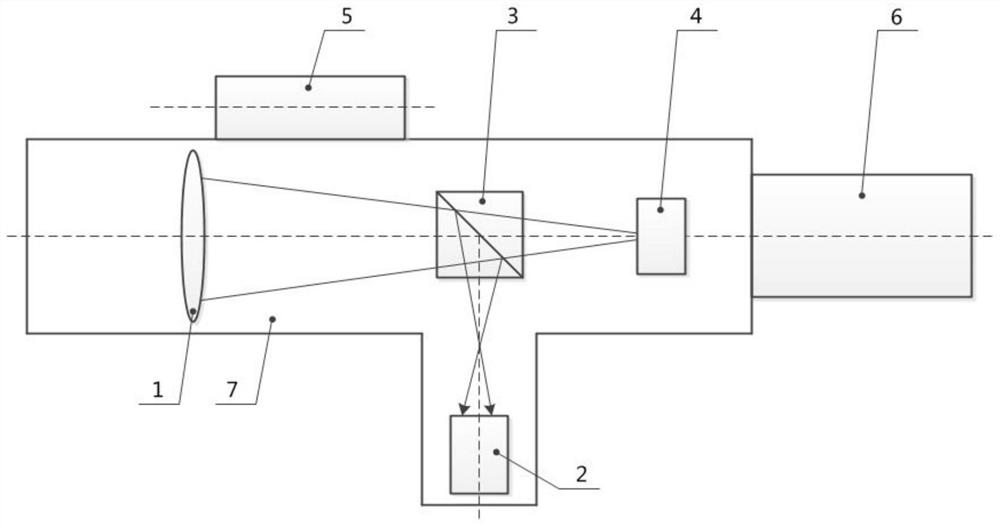

[0029] This embodiment proposes a portable multi-condition universal shaft alignment device, such as figure 1 As shown, the device includes: an optical objective lens assembly 1 , an optical eyepiece assembly 2 , a beam splitter 3 , an imaging display assembly 4 , a laser assembly 5 , a centering barrel 6 and a lens barrel 7 .

[0030] The optical objective lens assembly 1, the incident optical axis of the beam splitter 3, the imaging display assembly 4 and the centering cylinder 6 are located on the same axis, the optical eyepiece assembly 2 and the exit optical axis of the beam splitter 3 are located on the same axis, and the optical axis of the laser assembly 5 is located on the same axis. It is placed off-axis from the optical axis of the optical objective lens assembly 1. The optical objective lens assembly 1, the optical eyepiece assembly 2, the beam splitter 3, the imaging display assembly 4, the laser assembly 5, and the centering barrel 6 are all directly or indirectly...

Embodiment 2

[0036] Based on the above-mentioned Embodiment 1, further function expansion can be performed to realize the function and performance improvement of the device.

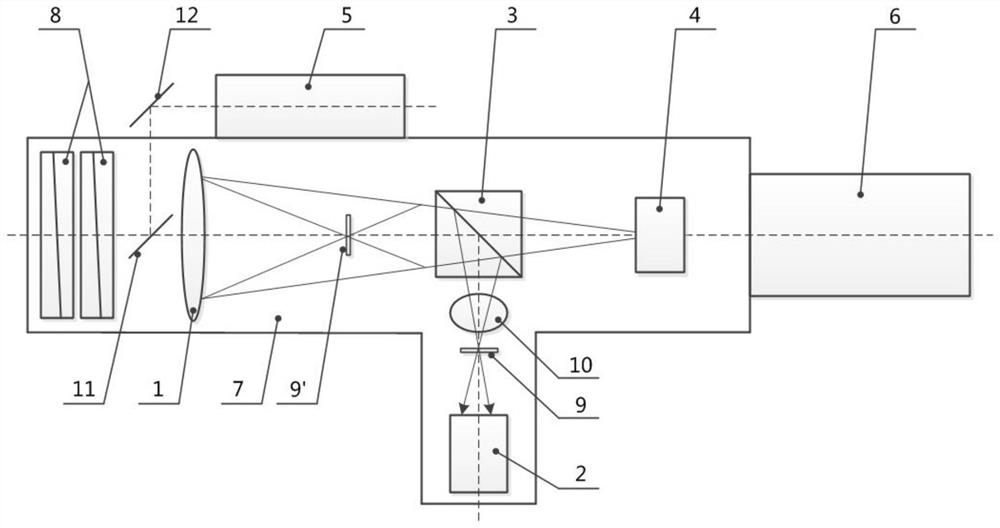

[0037] This embodiment proposes a portable multi-condition universal shaft alignment device, such as figure 2 As shown, as in Embodiment 1, including: optical objective lens assembly 1, optical eyepiece assembly 2, beam splitter 3, imaging display assembly 4, laser assembly 5, centering barrel 6 and lens barrel 7, the device also includes: The double wedge mirror group 8 , the optical reticle A9 , the optical reticle B9 ′, the additional plane mirror 10 , the first plane mirror 11 and the second plane mirror 12 .

[0038] One or two sets of double wedge lens groups 8 are located at the front end of the optical objective lens assembly 1 , and the purpose is to adjust or compensate the overall optical axis orientation of the axis alignment device. The double optical wedge lens group 8 is fixed on the lens barrel 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com