Method and system for measuring shield tail gap of shield tunneling machine based on double-line laser vision

A technology of shield tail clearance and measurement method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of low accuracy, data cannot be automatically saved and managed, laborious, etc., and achieve stable and reliable accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

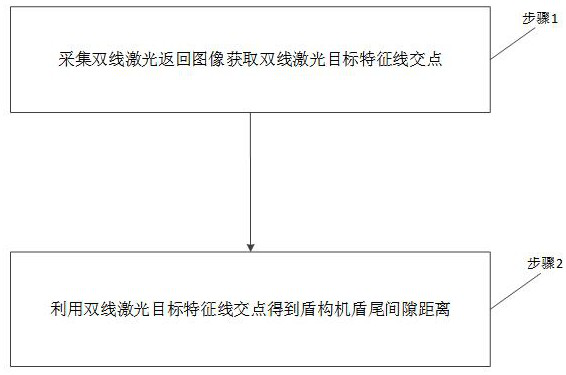

[0046] The invention provides a shield tail gap measurement method based on two-line laser vision, such as figure 1 shown, including:

[0047] Step 1: Collect the double-line laser return image to obtain the intersection point of the double-line laser target feature line;

[0048] Step 2: Use the intersection point of the two-line laser target feature line to obtain the shield tail clearance distance of the shield machine.

[0049] Step one specifically includes:

[0050] 1-1: Extract the pixel point data of the double-line laser return image by using the double-line laser return image;

[0051]1-2: Use the pixel point data of the double-line laser return image to calculate the line equation of the double-line laser return image based on the Hough line fitting algorithm;

[0052] 1-3: Use the linear equation of the double-line laser return image to calculate the intersection point of the double-line laser target feature line;

[0053] Wherein, the double-line laser return ...

Embodiment 2

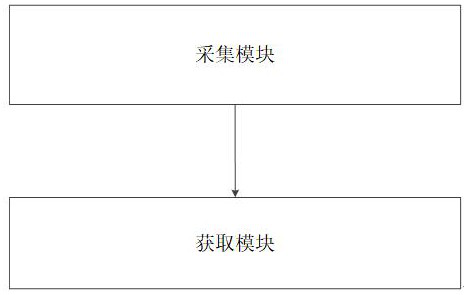

[0082] The invention provides a shield tail gap measurement system based on two-line laser vision, such as figure 2 shown, including:

[0083] The collection module is used to collect the return image of the double-line laser to obtain the intersection point of the characteristic line of the double-line laser target;

[0084] The acquisition module is used to obtain the shield tail gap distance of the shield machine by using the intersection point of the characteristic line of the double-line laser target.

Embodiment 3

[0086] The present invention provides a practical application method for shield tail gap measurement of shield machine based on two-line laser vision, including:

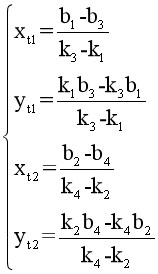

[0087] Use the image processing algorithm to extract the two segment lines projected on the segment by the laser structure line in the image and the two shield shell lines on the shield tail shell, extract the pixel point information of the spot, and use the Hough line fitting algorithm to obtain the segment The effective spot slope and straight line equation of the line and the shield shell line, where the straight line equation of the segment line and the shield shell line is as follows:

[0088]

[0089] Among them, y is the y-axis coordinate value of the image pixel point data returned by the two-line laser, x is the x-axis coordinate value of the image pixel point data returned by the two-line laser, k 管_1 is the straight line slope of the first segment line laser return image pixel point, b 管_1 The straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com